Array type plasma device for material surface treatment

A plasma and surface treatment technology, applied in the direction of plasma, electrical components, etc., can solve the problems of difficult processing, large area processing of difficult materials, poor timeliness, etc., to improve stability and timeliness, increase processing area, reduce Effects of processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below with examples, so as to fully understand and implement the implementation process of how the present invention uses technical means to solve technical problems and achieve technical effects.

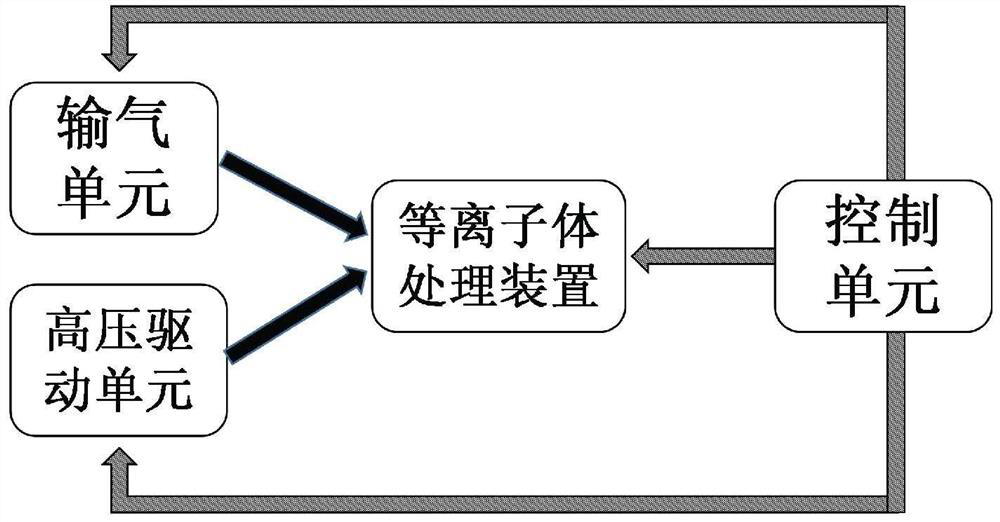

[0029] The embodiment of the present invention discloses an array plasma device for surface treatment of materials, the schematic diagram of which is shown in figure 1 As shown, it includes a plasma processing device, a high-voltage drive unit, a gas delivery unit and a control unit.

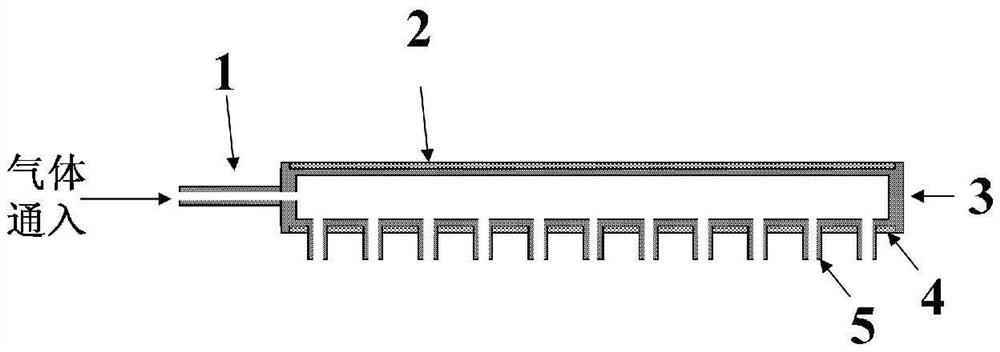

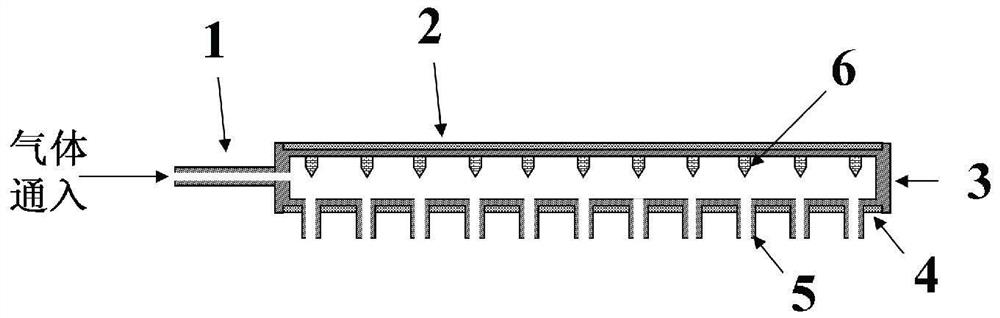

[0030] Such as figure 2 with image 3 As shown, the plasma processing device is equipped with a discharge gas chamber 3, the discharge gas chamber 3 is provided with a gas inlet 1, the upper part of the discharge gas chamber 3 is connected to the high voltage plate electrode 2, and the lower part is connected to the orifice plate electrode 4, and the high voltage plate electrode 3 and the grounded perforated plate elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com