Tribasic copper chloride microspheres, preparation method thereof and feed additive

A copper chloride, basic technology, applied in the field of basic copper chloride microspheres and its preparation, and feed additives, can solve copper pollution, copper poisoning and other problems, achieve low environmental pollution, large specific surface area, and strong safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

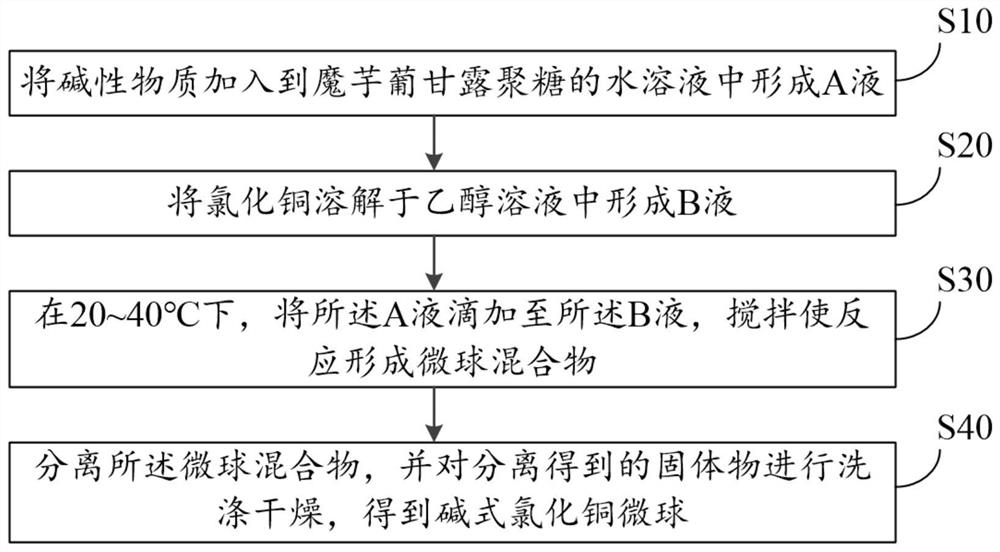

[0036] refer to figure 1 , in the present embodiment, the preparation method of described basic cupric chloride microspheres comprises the following steps:

[0037] Step S10, adding alkaline substances into the aqueous solution of konjac glucomannan to form A liquid.

[0038] Step S20, dissolving copper chloride in ethanol solution to form B solution.

[0039] In this embodiment, liquid A and liquid B are prepared in advance. It should be noted that, in actual implementation, step S10 and step S20 have no sequence, and step S10 can be performed before, after or at the same time as step S20.

[0040] Wherein, the alkaline substance may be common alkaline reagents such as ammonia water, sodium hydroxide, potassium hydroxide, and calcium hydroxide. Further, considering that compared with sodium hydroxide and potassium hydroxide, when selecting calcium hydroxide or ammoniacal liquor as raw material, the purity of the basic cupric chloride microspheres of generation is lower, and...

Embodiment 1

[0057] Add 6.0g NaOH to 300mL 3% aqueous solution of konjac glucomannan, stir to dissolve and form A liquid; add 13.44g CuCl 2 Add to 50mL 95% ethanol solution, stir to dissolve, filter and collect the filtrate to obtain liquid B.

[0058] Transfer liquid B to a 500mL round-bottomed flask, stir with a constant temperature heating magnetic stirrer, and keep the solution temperature at 30°C, add liquid A slowly and uniformly within 50 minutes, and react for another 60 minutes. After the reaction, the obtained The microsphere mixture was centrifuged, the precipitate was separated and washed with water, and the obtained precipitate was dried in a drying oven at 105° C. for 1 h to obtain a green powder.

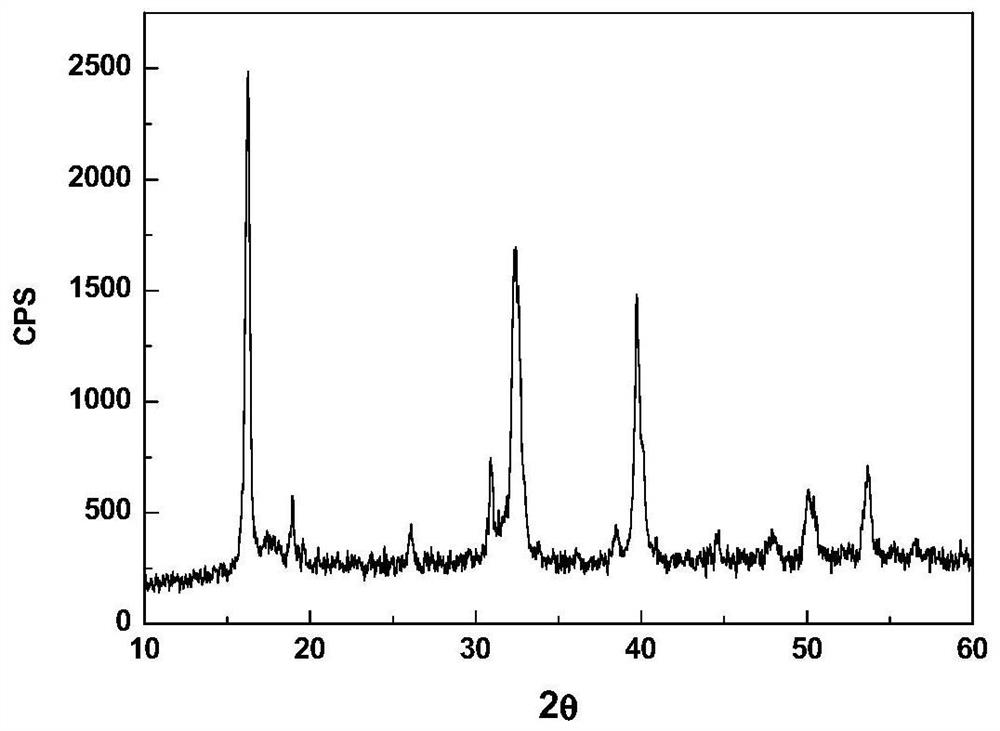

[0059] Carry out XRD measurement to green powder, the result is as follows figure 2 As shown, it can be seen from the figure that the peak positions 2θ are 16.28°, 18.91°, 26.11°, 30.89°, 32.21°, 32.42°, 32.62°, 32.93°, 38.39°, 39.67°, 40.13°, 40.87° °, 44.60 °, 47.89 °, 49.87 ...

Embodiment 2

[0062] Add 8.96g NaOH to 560mL 2% aqueous solution of konjac glucomannan, stir to dissolve and form A liquid; add 20.40g CuCl 2 Add to 70mL 95% ethanol solution, stir to dissolve, filter and collect the filtrate to obtain liquid B.

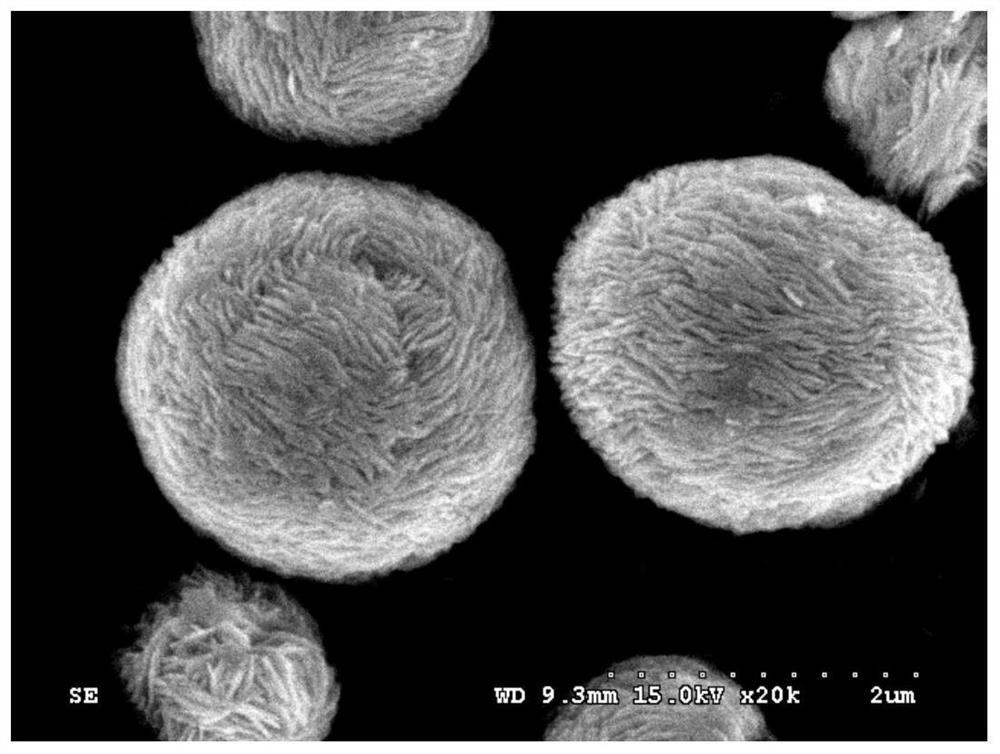

[0063] Transfer liquid B to a 1000mL round-bottomed flask, stir with a constant temperature heating magnetic stirrer, and keep the solution temperature at 20°C, add liquid A slowly and uniformly within 60 minutes, and react for another 90 minutes. After the reaction, the obtained The microsphere mixture was centrifuged, the precipitate was separated and washed with water, and the obtained precipitate was dried in a drying oven at 100°C for 2 hours to obtain a green powder, which was basic copper chloride microspheres, and basic copper chloride microspheres The balls are in the shape of wire balls, with a particle size of 1-3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com