Aluminum-silicon alloy powder for 3D printing and preparation method thereof

An aluminum-silicon alloy and 3D printing technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the technical difficulty of increasing raw material powder preparation and printing, fail to control the performance of aluminum powder from the source, and cannot be large Large-scale production and other issues, to achieve the effect of convenient and fast preparation technology, excellent mechanical properties, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method for aluminum-silicon alloy powder for 3D printing, comprising the following steps:

[0038] The aluminum-silicon alloy raw material is heated and melted in vacuum within the range of 630°C-700°C and kept for a period of time to make it fully mixed and uniform. The content is 15%wt-30%wt, the content of Fe is not more than 0.3wt%, the content of Cu is not more than 0.15wt%, and the rest is Al;

[0039]Use high-speed compressed airflow (high-purity argon or nitrogen) to impact the molten aluminum-silicon alloy flow, the gas pressure of the high-speed compressed airflow is 1.6-2.5MPa, and adopt a tightly coupled method to ensure that the negative pressure at the outlet is 0.3-0.7kPa. It is broken into aerosolized particles, and the high-speed compressed airflow hits the molten aluminum-silicon alloy flow using a supersonic atomizing nozzle that combines laval and hartmann structures. For the specific structure of the supersonic atomizing nozzle fused ...

Embodiment 1

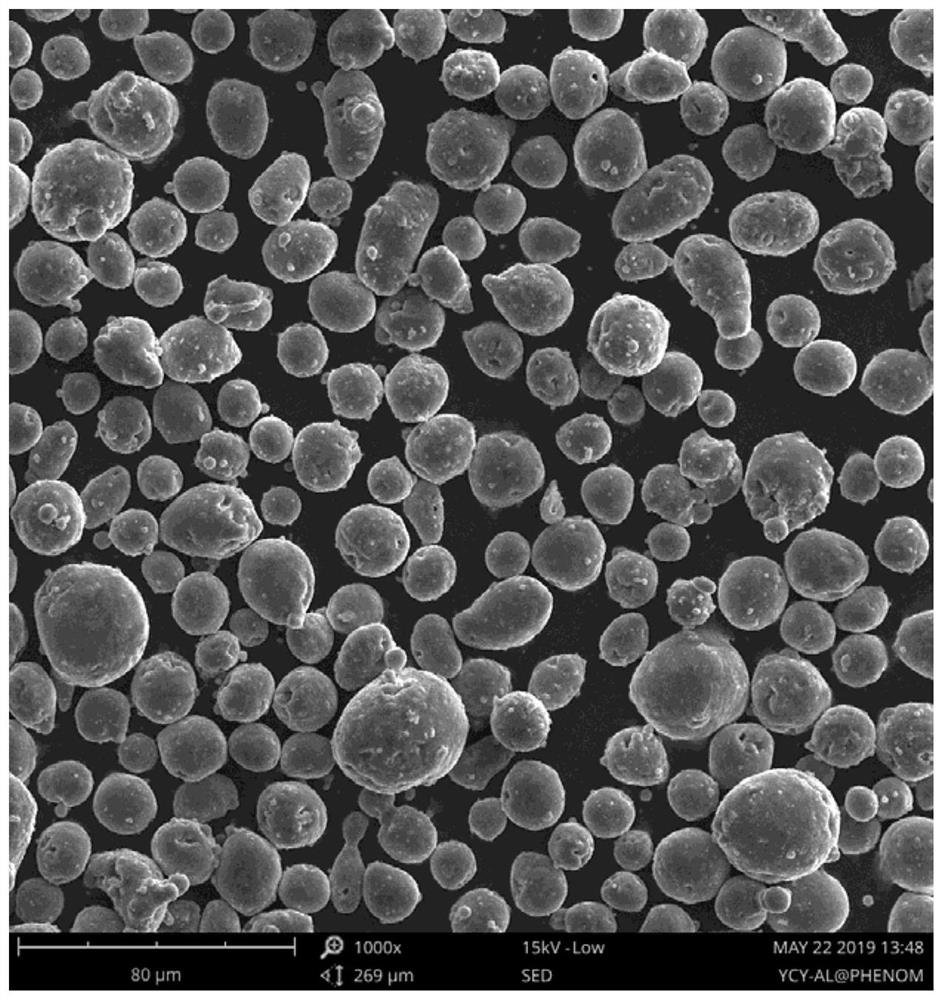

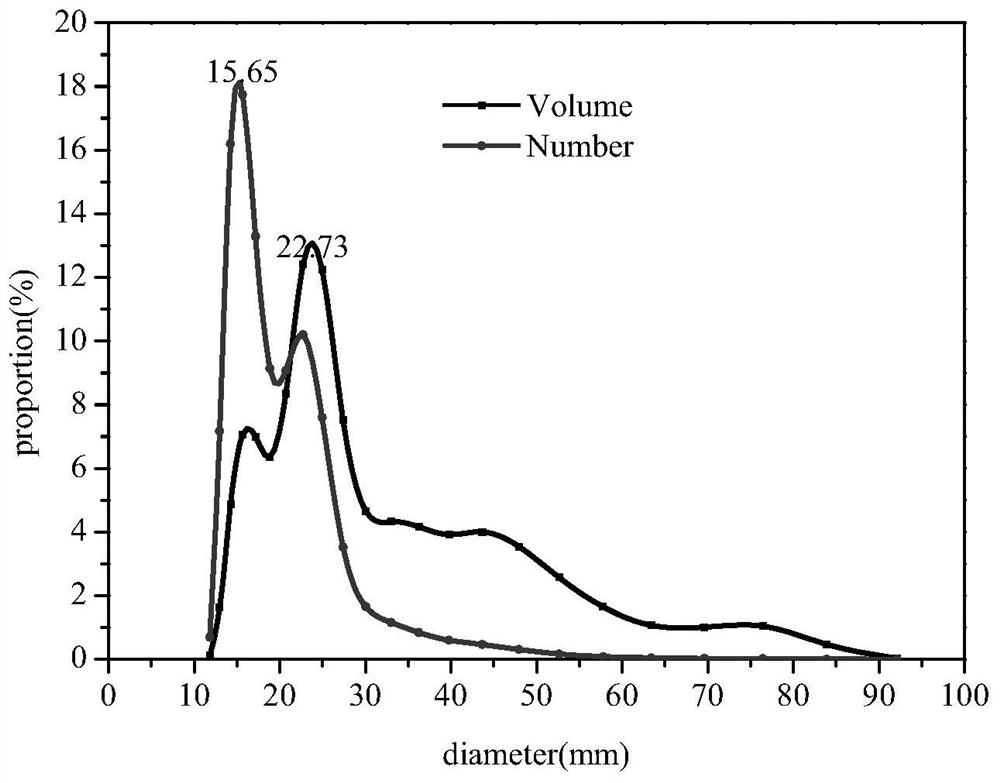

[0045] According to the mass ratio of 4:1, the aluminum-silicon raw materials were taken respectively, heated and melted in vacuum at 660°C and kept for half an hour, and then the high-speed compressed airflow was used to impact the molten aluminum-silicon alloy flow, and the specific structure of the supersonic atomizing nozzle combined with the laval and hartmann structure could be Refer to the supersonic atomizing nozzle disclosed in Chinese patent CN201410553271.X, which is a fusion of two-stage laval and hartmann structures. The atomizing gas is high-purity argon, and the gas pressure during atomization is 2MPa. The tight coupling method is adopted to ensure negative pressure at the outlet. At 0.5kPa, the primary resonance gas frequency is 100kHz. After the gas is atomized, the powder with a particle size of 10-45 μm is screened out by cyclone classification and collected to obtain aluminum-silicon alloy powder.

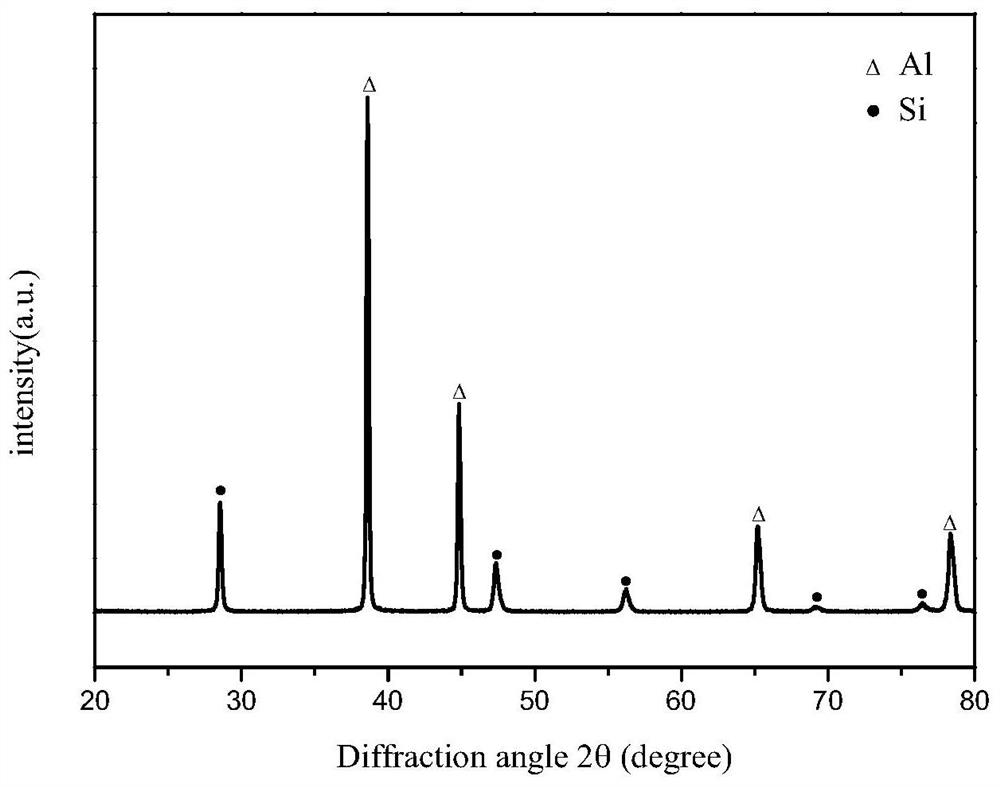

[0046] The composition of Al-Si alloy powder was analyzed ...

Embodiment 2

[0055] A preparation method for aluminum-silicon alloy powder for 3D printing, comprising the following steps:

[0056] The aluminum-silicon alloy raw material is heated and melted in a vacuum within the range of 630°C for a period of time, so that it is fully mixed and evenly mixed. The ratio of silicon and aluminum in the aluminum-silicon alloy raw material meets the Si content of the final aluminum-silicon alloy powder used for 3D printing. %wt, Al content is 84.6%wt, Fe content is 0.28wt%, Cu content is 0.12wt%,

[0057] Use high-speed compressed airflow (high-purity argon gas) to impact the molten aluminum-silicon alloy flow. The gas pressure of the high-speed compressed airflow is 1.6MPa. The tight coupling method is adopted to ensure that the negative pressure at the outlet is 0.3kPa, and it is broken into aerosol. The high-speed compressed airflow impinges on the molten aluminum-silicon alloy flow using a supersonic atomizing nozzle that combines laval and hartmann str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com