Method for preparing sheet molecular sieve membrane support body by using natural attapulgite

A technology of attapulgite and attapulgite powder, which is applied in the application, household appliances, manufacturing tools and other directions, can solve the problems of poor economic benefit, easy falling off of the film surface, uneven pores, etc., and achieves clean and smooth appearance, good practical value, The effect of shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a thin molecular sieve membrane support by using natural attapulgite, specifically implemented according to the following steps:

[0043] Step 1, mix the natural attapulgite powder and soluble starch evenly according to the mass ratio of 50:3 to form a mixture; take 5g of the obtained mixture and put it into a ball mill tank with a volume of 20mL, and mix and stir evenly for 20 minutes;

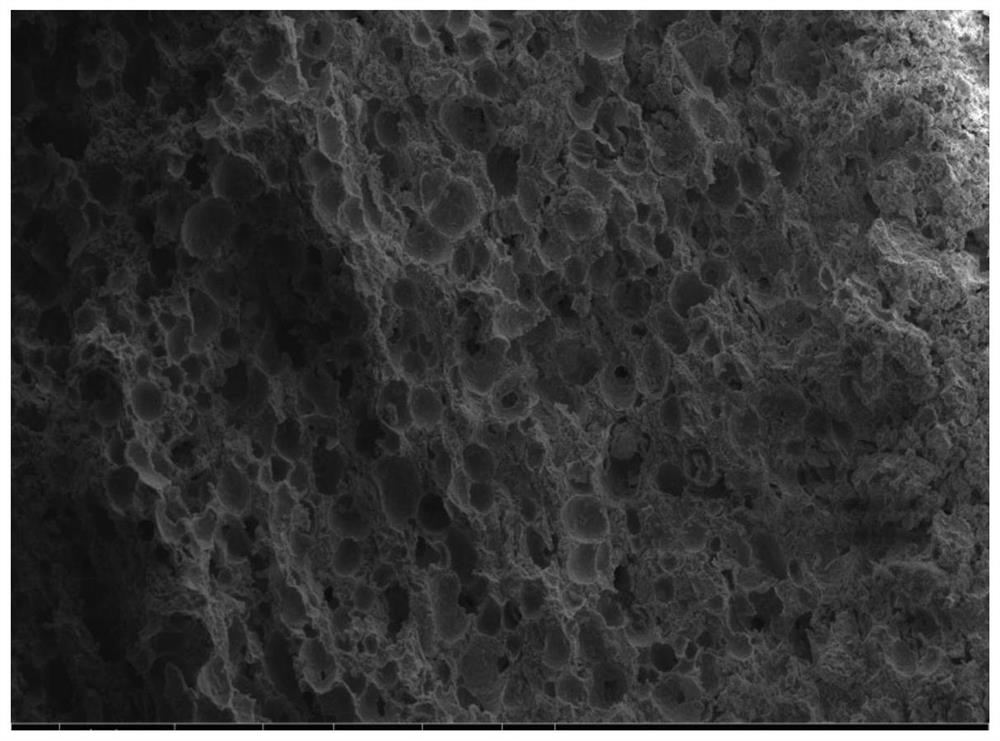

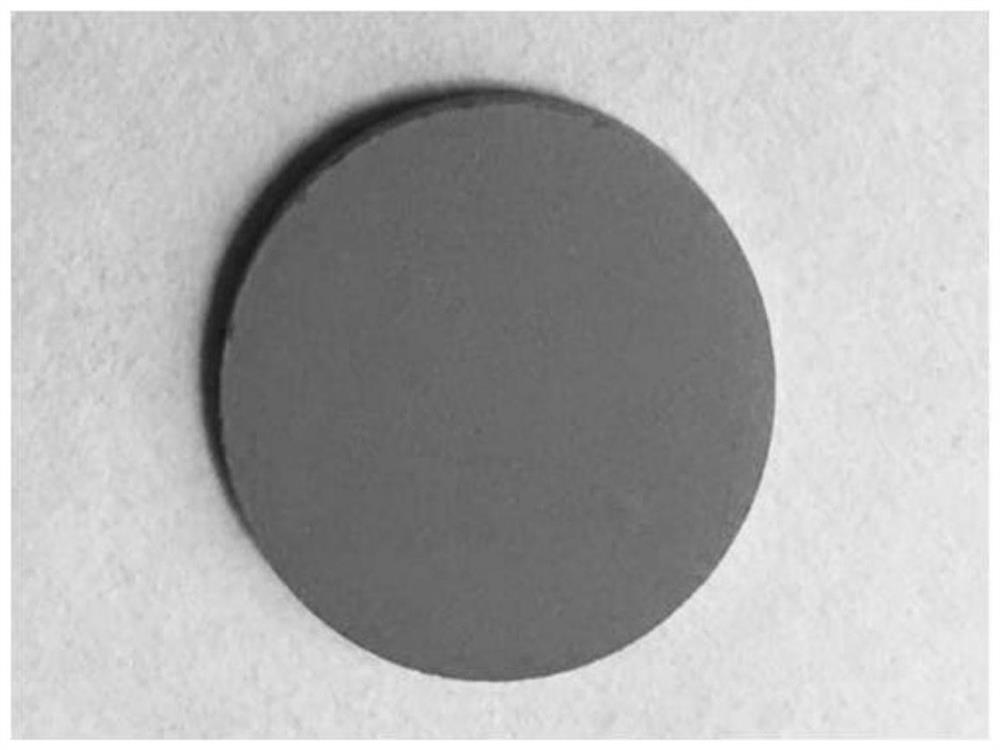

[0044] Step 2: Put the uniformly mixed material in step 1 into an oven and heat at 110°C for 2 hours, take it out after drying, cool it, transfer it to a 200mL agate mortar for grinding, pass through a 200-mesh sieve to obtain a uniform powder with a diameter of no more than 75μm, and use a powder tablet machine. In a circular mold with a diameter of 20mm, the pressure is 10MPa, the pressing time is 100s, and the pressure relief time is 120s, and the molding is performed;

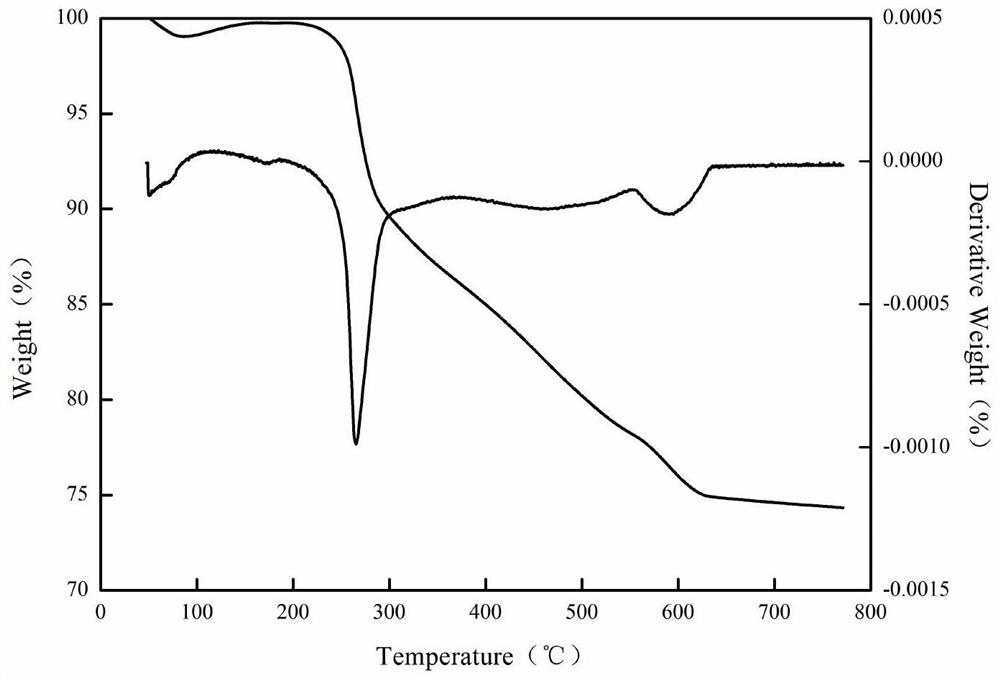

[0045] Step 3, put the green body obtained in step 2 in a muffle furnace, and roast it in ...

Embodiment 2

[0048] A method for preparing a thin molecular sieve membrane support by using natural attapulgite, specifically implemented according to the following steps:

[0049] Step 1, mix the natural attapulgite powder and cellulose evenly according to the mass ratio of 100:5 to form a mixture; take 5g of the obtained mixture and put it into a ball mill tank with a volume of 20mL, and mix and stir evenly for 30 minutes;

[0050] Step 2: Put the uniformly mixed material in step 1 into an oven and heat at 110°C for 2 hours, take it out after drying, cool it, transfer it to a 200mL agate mortar and grind it, pass it through a 200-mesh sieve to obtain a uniform powder with a diameter of no more than 60 μm, and use a powder tablet machine. In a circular mold with a diameter of 20 mm, the pressure is 15 MPa, the pressing time is 100 s, and the pressure release time is 120 s, and the press is formed;

[0051] In step 3, the green body obtained in step 2 is placed in a muffle furnace, and fir...

Embodiment 3

[0054] A method for preparing a thin molecular sieve membrane support by using natural attapulgite, specifically implemented according to the following steps:

[0055] Step 1, mix the natural attapulgite powder and polyethylene evenly according to the mass ratio of 100:3 to form a mixture; take 5g of the obtained mixture and put it into a ball mill tank with a volume of 20mL, and mix and stir evenly for 15 minutes;

[0056] Step 2: Put the uniformly mixed material in step 1 into an oven and heat at 110°C for 2 hours, take it out after drying, cool it, transfer it to a 200mL agate mortar and grind it, pass it through a 200-mesh sieve to obtain a uniform powder with a diameter of no more than 80 μm, and use a powder tablet machine. In a circular mold with a diameter of 20mm, the pressure is 15MPa, the pressing time is 150s, and the pressure relief time is 200s, and the molding is performed;

[0057] In step 3, the green body obtained in step 2 is placed in a muffle furnace, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com