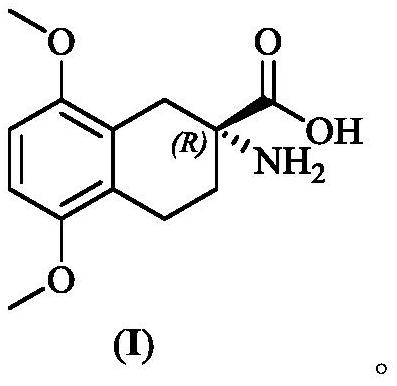

Amrubicin hydrochloride intermediate compound I

A technology of amrubicin hydrochloride and amrubicin, which is applied in the field of medicine, can solve the problems of low conversion rate and long production cycle, and achieve the effects of high conversion rate, reduced splitting, and mild use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

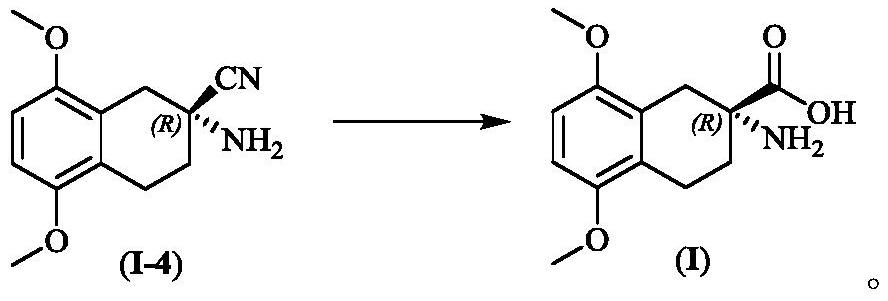

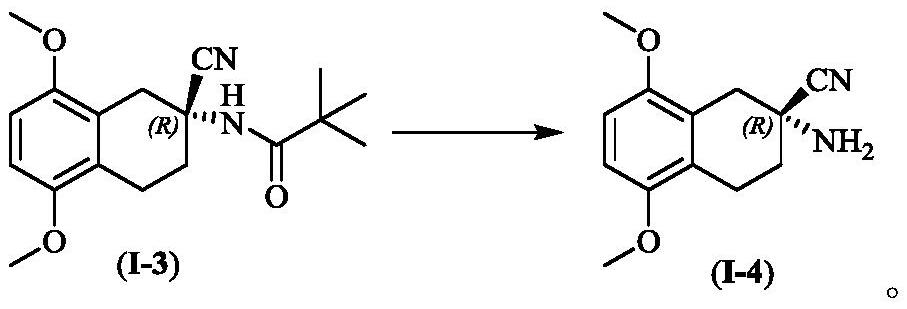

Method used

Image

Examples

Embodiment 1

[0083] Under argon protection, at room temperature, add I-1 (10.31g, 0.050mol), (R)-tert-butylsulfinamide (9.70g, 0.080mol) and tetrabutyl titanate (28.93g, 0.085mol) In dry tetrahydrofuran (200mL), react at 40-45°C for 3 hours. After the reaction is detected, pour the reaction solution into saturated aqueous sodium carbonate solution (200mL), extract with dichloromethane (150mL×2), and place it on a pad of silicon Filter through alginate, dry the filtrate with anhydrous sodium sulfate, filter, and concentrate the filtrate to dryness under reduced pressure to obtain I-2, with a molar yield of 94.9%, a purity of 99.74% by HPLC, and an optical purity of 99.98% by HPLC.

Embodiment 2

[0085] Under argon protection, at room temperature, I-1 (10.31g, 0.050mol), (R)-tert-butylsulfinamide (6.67g, 0.055mol) and tetrabutyl titanate (28.93g, 0.085mol) were added In dry chloroform (220mL), react at 40-45°C for 3 hours. After the reaction is detected, pour the reaction solution into saturated aqueous sodium carbonate solution (200mL), extract with chloroform (150mL×2), and pad with diatomaceous earth After filtration, the filtrate was dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness under reduced pressure to obtain I-2, with a molar yield of 92.6%, a purity of 99.60% by HPLC, and an optical purity of 99.98% by HPLC.

Embodiment 3

[0087]Under argon protection, at room temperature, add I-1 (10.31g, 0.050mol), (R)-tert-butylsulfinamide (6.06g, 0.050mol) and tetrabutyl titanate (28.93g, 0.085mol) In dry tetrahydrofuran (200mL), react at 40-45°C for 3 hours. After the completion of the reaction, pour the reaction solution into saturated aqueous sodium carbonate solution (200mL), extract with dichloromethane (150mL×2), pad silicon After filtration with alginate, the filtrate was dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness under reduced pressure to obtain I-2. The molar yield was 91.2%. The purity by HPLC was 99.58%, and the optical purity by HPLC was 99.97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com