Tetrahedral amorphous carbon film, as well as preparation method and application thereof

A tetrahedral amorphous carbon and matrix technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of film macro-large particle deposition pollution, short arc spot life, and difficult to obtain tetrahedral amorphous Carbon film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] An aspect of the embodiments of the present invention provides a method for preparing a tetrahedral amorphous carbon film, which includes:

[0021] Etching the surface of the substrate; and,

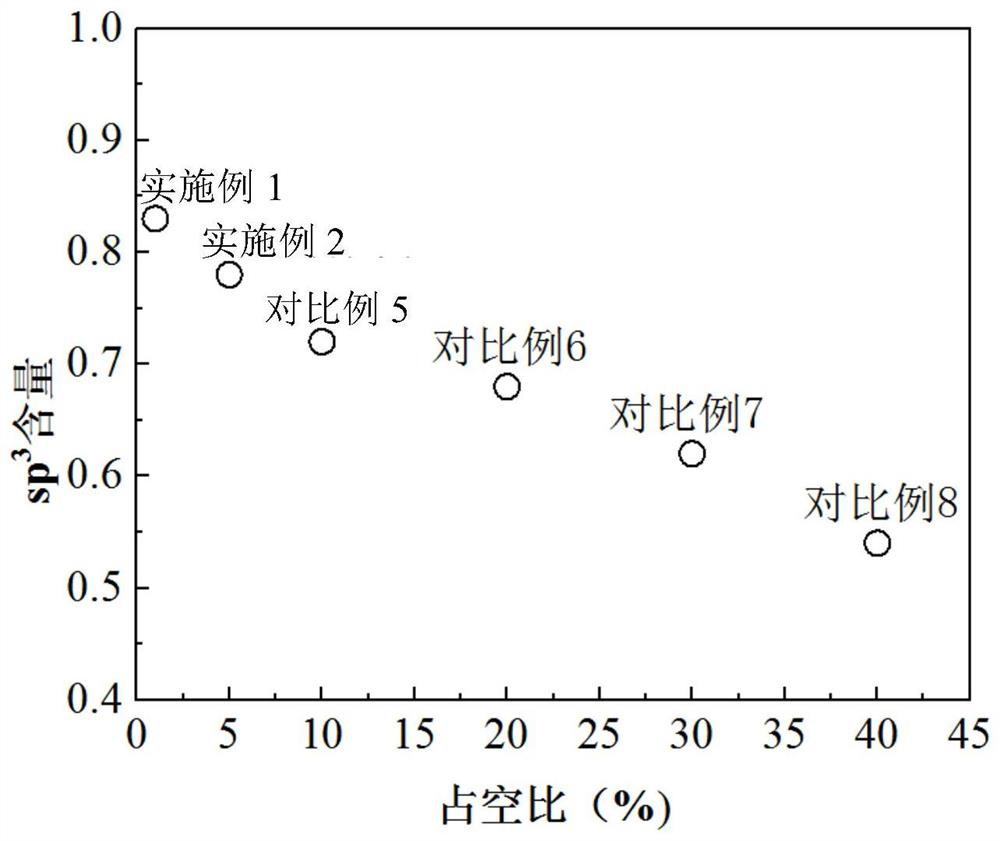

[0022] Using high-power pulse magnetron sputtering technology, graphite target is used as the target material, and a tetrahedral amorphous carbon film is deposited on the surface of the substrate, wherein the high-power pulse duty ratio is 1% to 5%, and the sputtering power is 700~1000W, the substrate temperature is less than 50℃.

[0023] In some more specific embodiments, the preparation method includes: using high-power pulsed magnetron sputtering technology, using a graphite target as a target material, and an inert gas as a working gas, applying a pulsed negative bias to the substrate, thereby A tetrahedral amorphous carbon film is deposited on the surface of the substrate, wherein the chamber pressure is 0.2-0.3Pa, the high-power pulse frequency is 200-250Hz, the pulse widt...

Embodiment 1

[0041] After the substrate was cleaned, it was fixed in a vacuum chamber and vacuumed to 5.0×10 -3 Below Pa, then pass argon gas into the cavity, adjust the cavity pressure to 2Pa, apply pulse negative bias voltage to the substrate to generate gas glow discharge, and etch the substrate? min, the substrate pulse negative bias voltage is -600V; after that, argon gas is introduced into the cavity, and the cavity pressure is adjusted to 0.25Pa, and a tetrahedral amorphous carbon film is prepared on the surface of the substrate by high-power pulse magnetron sputtering. It is a graphite target, where the high-power pulse frequency is 200Hz, the pulse width is 50μs, the pulse duty ratio is 1%, the sputtering power is 700W, and the pulse negative bias voltage -50V is applied to the substrate during the sputtering process, and the substrate temperature is from room temperature to 35°C, the deposition time is 30min, after testing, in the prepared tetrahedral amorphous carbon film struct...

Embodiment 2

[0043]After the substrate was cleaned, it was fixed in a vacuum chamber and vacuumed to 5.0×10 -3 Below Pa, then pass argon gas into the cavity, adjust the cavity pressure to 2Pa, apply pulse negative bias voltage to the substrate to generate gas glow discharge, etch the substrate, and the substrate pulse negative bias voltage is -600V; Argon gas was introduced into the cavity, and the pressure of the cavity was adjusted to 0.25 Pa. A tetrahedral amorphous carbon film was prepared on the surface of the substrate by high-power pulse magnetron sputtering. The target material was a graphite target, and the high-power pulse frequency was 200 Hz. The width is 50μs, the pulse duty ratio is 1%, the sputtering power is 1000W, the pulse negative bias voltage -50V is applied to the substrate during the sputtering process, the substrate temperature is from room temperature to 45°C, and the deposition time is 30min. After testing, the prepared sp in the tetrahedral amorphous carbon film s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com