Method for preparing lithium battery SiO negative electrode material with high cycle performance

A technology of cycle performance and negative electrode material, applied in the direction of lithium battery, battery electrode, active material electrode, etc., can solve the problems of large volume expansion and cycle performance decline, reduce usage, improve specific capacity and cycle performance, and suppress volume The effect of the dilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

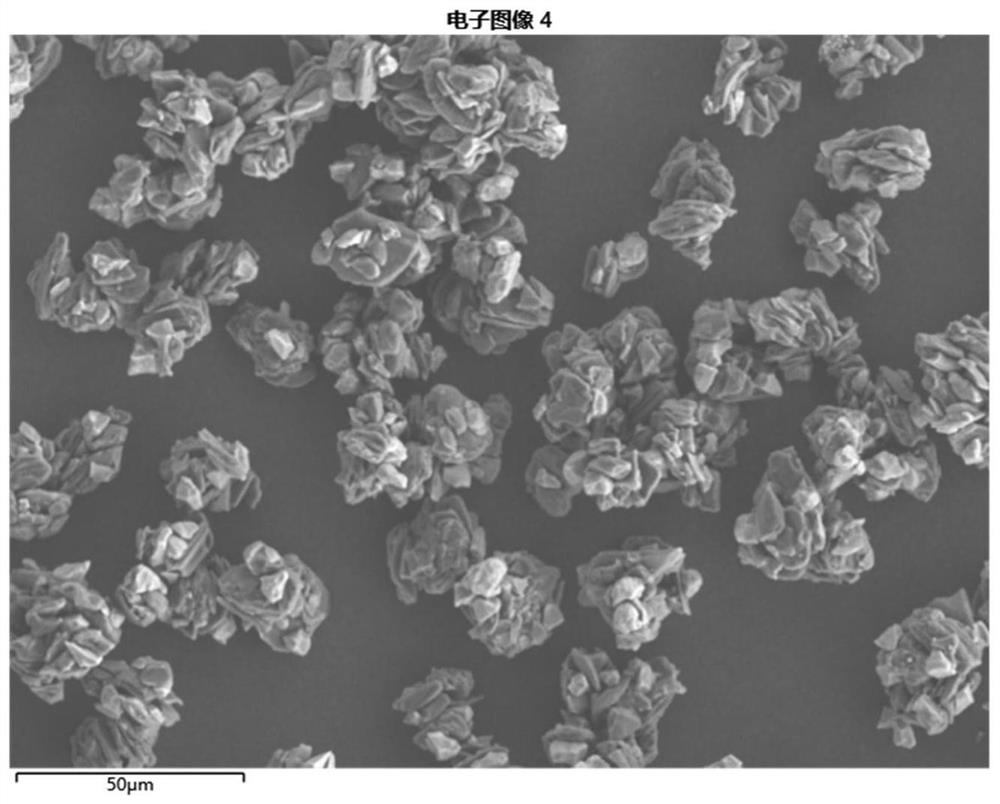

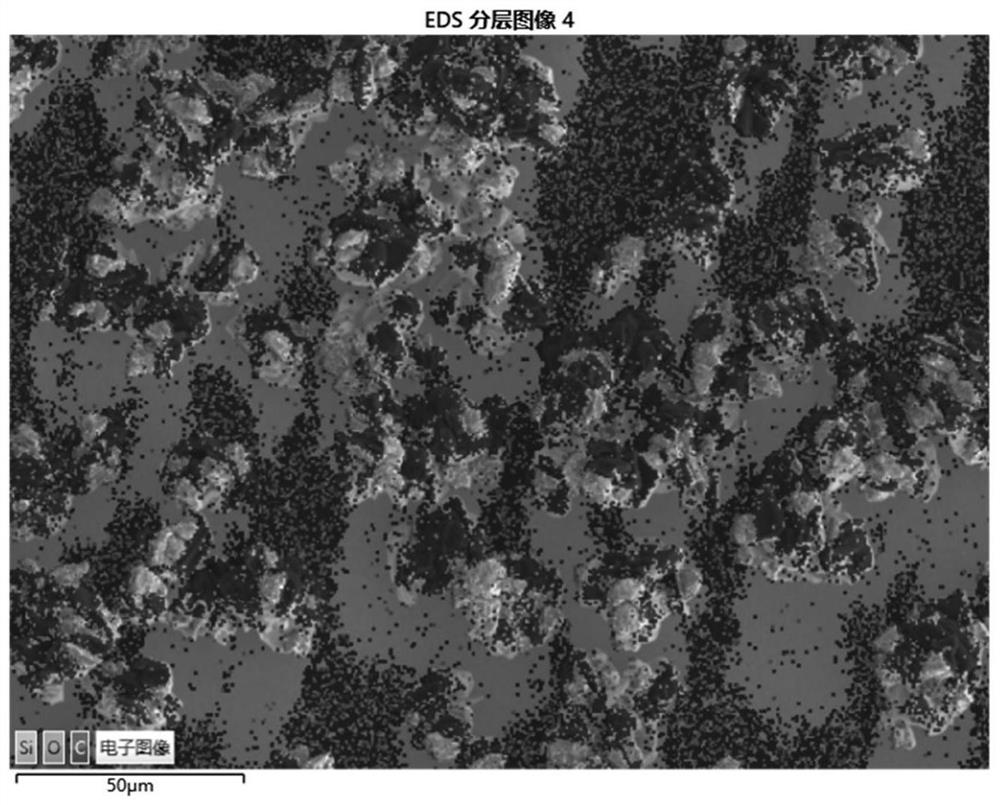

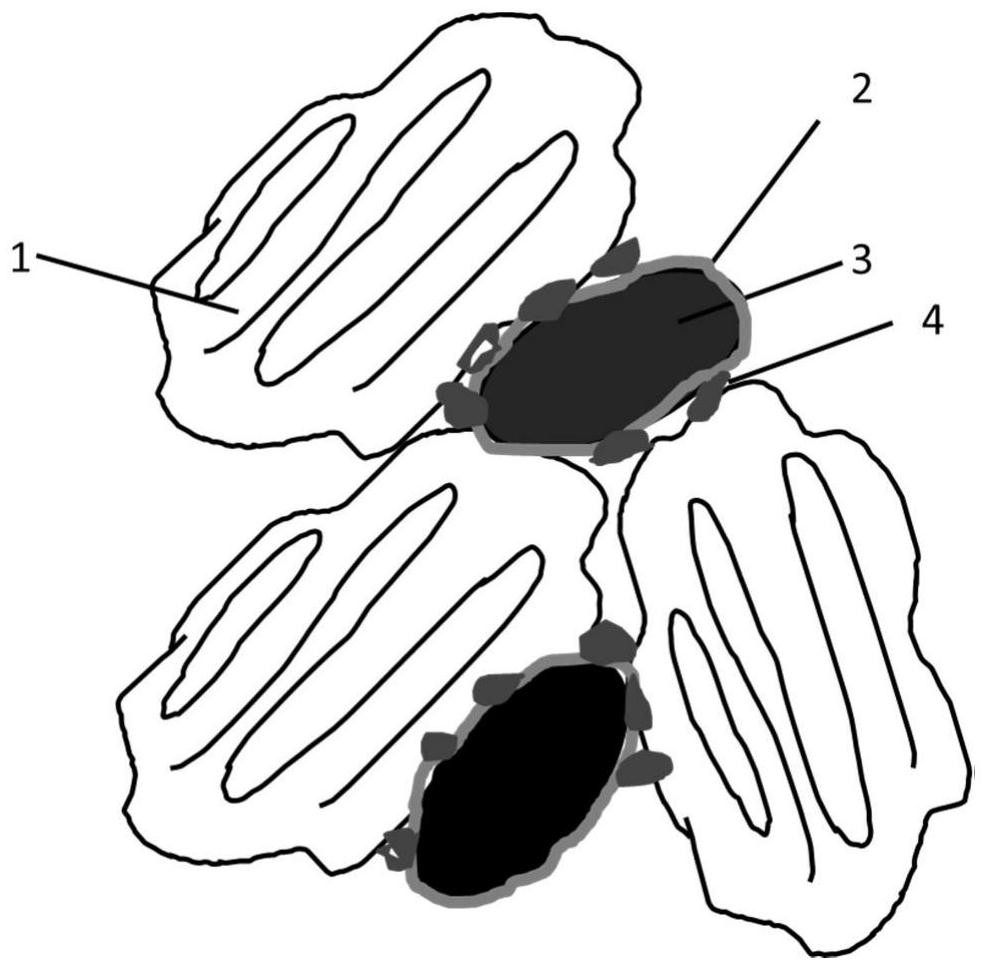

[0031] A method for preparing a lithium battery SiO negative electrode material with high cycle performance, comprising the following steps:

[0032] (1) According to the mass ratio of 1:0.1, take SiO with a particle size of 1 μm and coal tar with a viscosity of 0.1 Pa·s respectively, add them to the kneader, raise the temperature to 120°C and stir and knead for 2 hours to coat the surface of silicon oxide A layer of organic carbon sources yields complex A;

[0033] (2) Transfer composite A, artificial graphite with a particle size of 10 μm, and high-viscosity pitch with a viscosity of 5 Pa s to a vertical granulation kettle through a vacuum device according to a mass ratio of 1:6:0.2, and feed an inert atmosphere at a stirring speed of 100 revolutions per minute, heat at a rate of 3 °C / min to 300 °C for 1 hour, and then heat at a rate of 5 °C / min to 700 °C for 2 hours, and obtain composite material B after natural cooling;

[0034] (3) The composite material B was transferre...

Embodiment 2

[0036] A method for preparing a lithium battery SiO negative electrode material with high cycle performance, comprising the following steps:

[0037] (1) According to the mass ratio of 1:0.2, take SiO with a particle size of 1 μm and coal tar with a particle size of 0.2 Pa s respectively, add them to the kneader, raise the temperature to 100 ° C and knead for 2 hours, so that the surface of silicon oxide is coated with a layer organic carbon source to obtain complex A;

[0038] (2) The composite A, artificial graphite with a particle size of 10 μm, and high-viscosity pitch with a viscosity of 2 Pa s are transferred to a vertical granulation kettle through a vacuum device according to a mass ratio of 1:7:0.2, and the inert atmosphere is stirred. The speed is 100 rpm, and the heating rate is raised to 300°C at a heating rate of 3°C / min for 1 hour, and then the heating rate is raised to 700°C for 2 hours at a heating rate of 5°C / min, and the composite material B is obtained after...

Embodiment 3

[0041] A method for preparing a lithium battery SiO negative electrode material with high cycle performance, comprising the following steps:

[0042] (1) According to the mass ratio of 1:0.8, take SiO with a particle size of 1 μm and coal tar with a viscosity of 0.05 Pa·s respectively, add them to the kneader, raise the temperature to 150°C and stir and knead for 2 hours, so that the surface of silicon oxide is covered with Cover a layer of organic carbon source to obtain complex A;

[0043] (2) Transfer the mixed material, artificial graphite with a particle size of 10 μm, and high-viscosity asphalt with a viscosity of 6 Pa s to a vertical granulation kettle through a vacuum device according to a mass ratio of 1:7:0.2 and pass it into an inert atmosphere , stirring at a speed of 100 rpm, heating at a rate of 3 °C / min to 300 °C for 1 hour, then raising the rate of temperature at 5 °C / min to 700 °C for 2 hours, and cooling naturally to obtain a composite material B;

[0044] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com