Functional polysaccharide particle

A particle and cellulose technology, applied in the field of functional polysaccharide particles, can solve problems such as adverse effects on the ecosystem, and achieve the effect of excellent oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

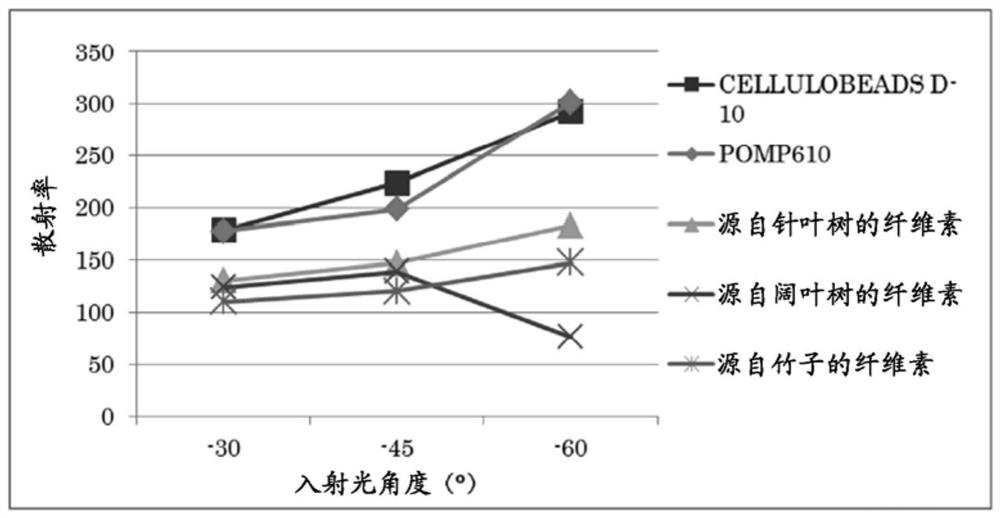

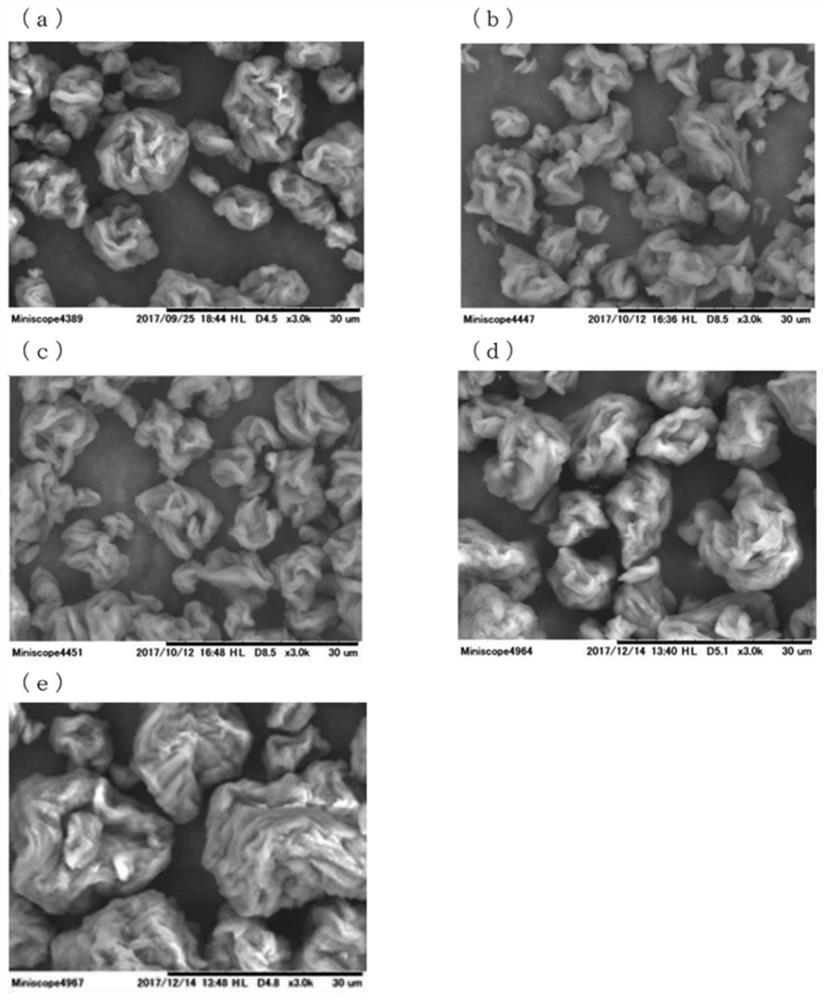

[0110] [Example 1: Bamboo-derived cellulose particles]

[0111] After adding 1343 g of pure water to 407 g of bamboo-derived cellulose nanofibers (manufactured by Chuetsu Pulp & Paper Co., Ltd.) with a solid content of 10% by mass, the mixture was stirred with a mechanical stirrer for 1 hour to disperse the cellulose nanofibers. This dispersion was pulverized 50 times under a pressure of 220 MPa using a wet micronizer Star Burst (manufactured by SUGINO MACHINE LIMITED CO., LTD.) to obtain a bamboo-derived cellulose nanofiber dispersion. 10 g of the obtained dispersion was put into a watch glass, and dried at 105° C. for 1 hour to remove water. The amount of the obtained residue was measured, and the cellulose concentration (solid content concentration) in water was calculated from the weight difference before and after drying. The resulting concentration was 2.0% by mass.

[0112] Spray-dry 1575 g of the above-mentioned bamboo-derived cellulose nanofiber dispersion for 75 mi...

Embodiment 2

[0113] [Example 2: Cellulose particles derived from broad-leaved trees]

[0114] After adding 400 g of pure water to 400 g of broad-leaved tree-derived cellulose nanofibers (manufactured by Daio Paper Co., Ltd.) with a solid content of 2% by mass, the cellulose nanofibers derived from broad-leaved trees were stirred for 1 hour with a mechanical stirrer. dispersion. 800 g of this dispersion was spray-dried for 26 minutes under the conditions of an atomizer rotation speed of 30,000 rpm, an inlet temperature of 182° C., and a cyclone differential pressure of 0.5 kPa to obtain 1.01 g of a powder as the title particle. During this period, the outlet temperature varied between 102°C and 77°C.

Embodiment 3

[0115] [Example 3: Cellulose particles derived from coniferous trees]

[0116] After adding 400 g of pure water to 400 g of conifer-derived cellulose nanofibers (manufactured by Daio Paper Co., Ltd.) with a solid content of 2% by mass, stir with a mechanical stirrer for 1 hour to make the conifer-derived cellulose nanofibers dispersion. 800 g of this dispersion was spray-dried for 26 minutes under the conditions of an atomizer rotation speed of 30,000 rpm, an inlet temperature of 178° C., and a cyclone differential pressure of 0.5 kPa to obtain 2.70 g of a powder as the title particle. During this period, the outlet temperature was kept constant at 17°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com