A kind of preparation method of high-strength antibacterial coated paper

A technology of coated paper and antibacterial agent is applied in the field of preparation of antibacterial coated paper, which can solve the problems of safety risks, poor barrier properties of antibacterial paper, low mechanical strength, etc., and achieves good promotion prospects, high barrier properties, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

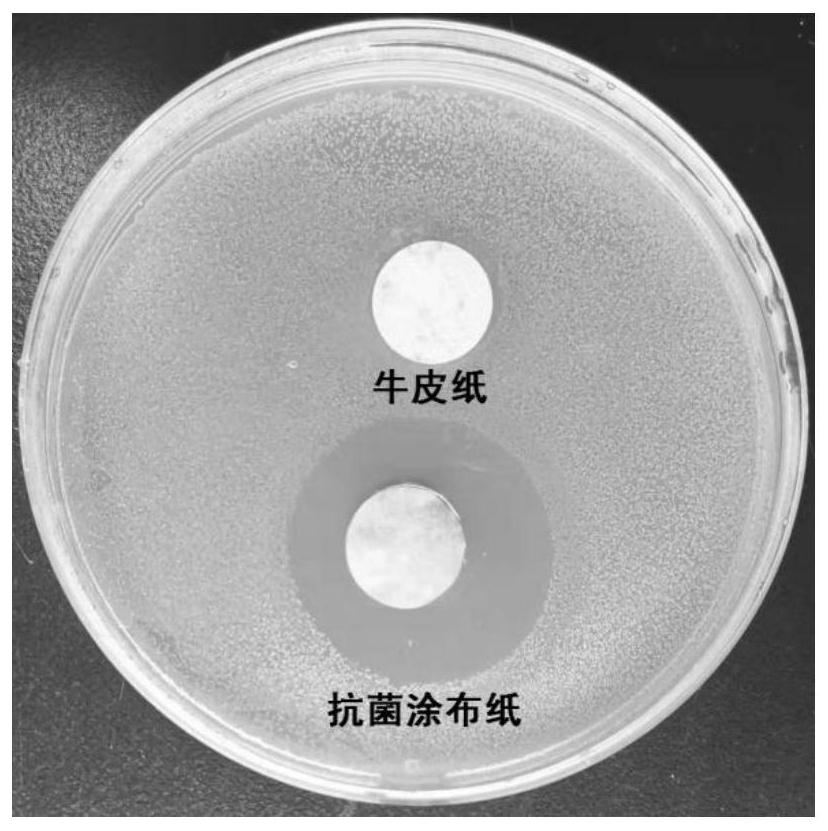

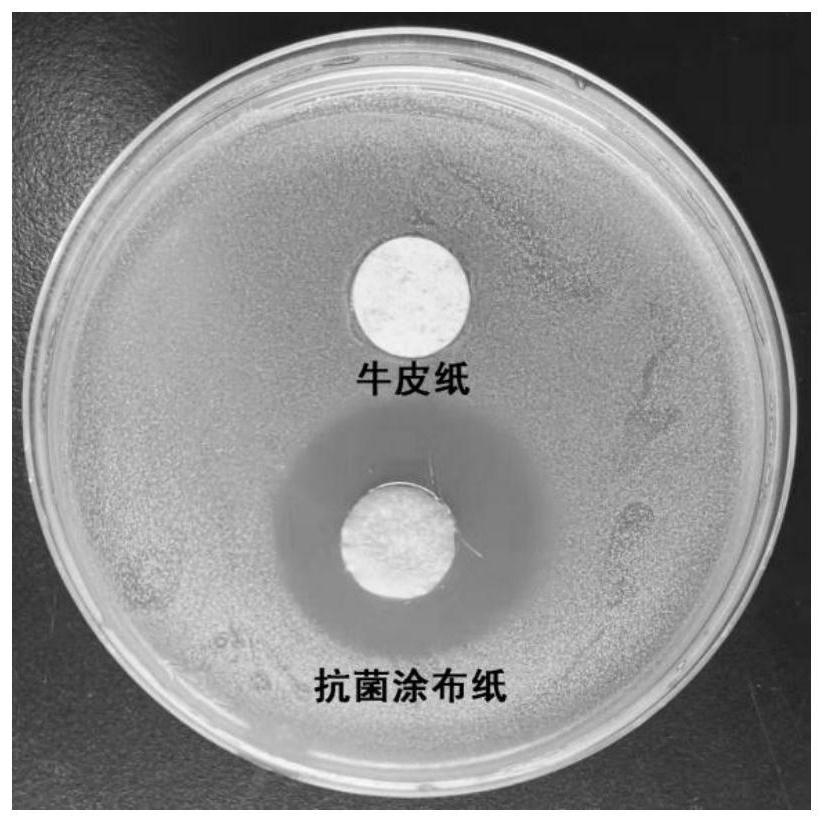

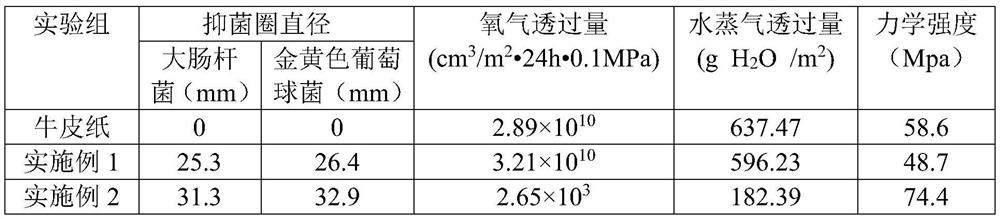

Embodiment 1

[0036] The cellulose pulp sheet was pulverized to obtain flocculent cellulose raw materials with an average length and diameter of 2.2 mm and 0.03 mm, respectively. Pour 40ml of acetic acid, 20ml of acetic anhydride and 0.05ml of concentrated sulfuric acid into a three-necked flask, add 10g of flocculent cellulose raw material under stirring with a 150rmp stirring paddle, dissolve and react at 60°C for 30min to obtain a cellulose solution. 2 ml of acetyl tributyl citrate and 6 g of thymol were successively added to the cellulose solution and stirred for 20 min to obtain an antibacterial coating solution. Next, the antibacterial coating liquid was coated on the surface of the kraft paper, and the coating amount was 20 g / m 2 , air-dried at room temperature for 2h. Finally, the air-dried coated paper was immersed in deionized water for 3 times, thoroughly washed away the residual solvent, and dried in a drum dryer to obtain an antibacterial coated paper.

Embodiment 2

[0038]The cellulose pulp sheet was pulverized to obtain flocculent cellulose raw materials with an average length and diameter of 2.2 mm and 0.03 mm, respectively. Pour 60ml of acetic acid, 40ml of acetic anhydride and 0.1ml of concentrated sulfuric acid into a three-necked flask, add 10g of flocculent cellulose raw materials under stirring with a 150rmp stirring paddle, dissolve and react at 60°C for 30min to obtain a cellulose solution. 2 ml of acetyl tributyl citrate and 6 g of thymol were successively added to the cellulose solution and stirred for 20 min to obtain an antibacterial coating solution. Next, the antibacterial coating liquid was coated on the surface of the kraft paper, and the coating amount was 20 g / m 2 , air-dried at room temperature for 2h. Finally, the air-dried coated paper was immersed in deionized water for 3 times, thoroughly washed away the residual solvent, and dried in a drum dryer to obtain an antibacterial coated paper.

Embodiment 3

[0040] The cellulose pulp sheet was pulverized to obtain flocculent cellulose raw materials with an average length and diameter of 2.2 mm and 0.03 mm, respectively. Pour 80ml of acetic acid, 60ml of acetic anhydride and 0.3ml of concentrated sulfuric acid into a three-necked flask, add 10g of flocculent cellulose raw material under stirring with a 150rmp stirring paddle, dissolve and react at 60°C for 30min to obtain a cellulose solution. 2 ml of acetyl tributyl citrate and 6 g of thymol were successively added to the cellulose solution and stirred for 20 min to obtain an antibacterial coating solution. Next, the antibacterial coating liquid was coated on the surface of the kraft paper, and the coating amount was 20 g / m 2 , air-dried at room temperature for 2h. Finally, the air-dried coated paper was immersed in deionized water for 3 times, thoroughly washed away the residual solvent, and dried in a drum dryer to obtain an antibacterial coated paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com