Method for determining calcium and magnesium ions in solution after chlorination of gasification slag and method for mineralizing solution after chlorination of gasification slag

A method for measuring calcium and magnesium ions, which is applied in the field of coal chemical industry, can solve the problems of difficulty in measuring the concentration of calcium and magnesium ions and large errors, and achieve the effect of retaining calcium ions, reducing content and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the present invention, the chlorinated solution of the gasified slag can be prepared by conventional preparation methods in the art, for example, the gasified slag can be dissolved with hydrochloric acid, so that Ca and Mg in the gasified slag can be dissolved by hydrochloric acid and enter the liquid phase to obtain The solution of gasification slag after chlorination. Preferably, the preparation method of the chlorinated gasification slag comprises: contacting the gasification slag and hydrochloric acid at 100-110°C for 1-3 hours, and then performing the second solid-liquid separation to obtain the chlorinated gasification slag The solution of the hydrochloric acid is used so that the pH of the solution after the gasification slag is chlorinated is 1-2. Wherein, the contacting is preferably carried out under oil bath conditions.

[0033] Wherein, the contacting process can be carried out under the condition of stirring, and the stirring rate is not particularly li...

Embodiment 1

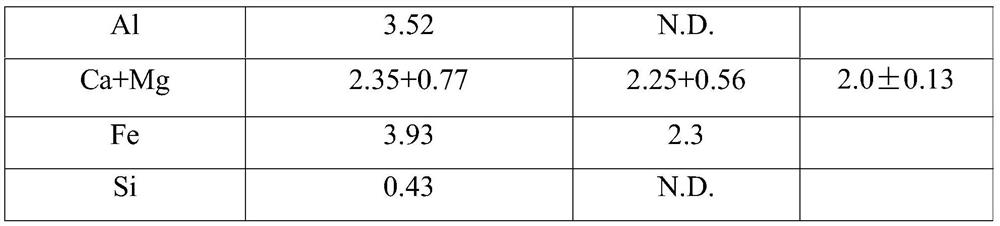

[0082] This embodiment is used to illustrate the determination method of calcium and magnesium ion concentration in the solution after gasification slag chlorination of the present invention

[0083] Use a pipette to draw 10ml of the chlorinated solution of gasification slag and add 80ml of deionized water to mix in a conical flask, then heat to boil and slowly add excess ammonia water to adjust the pH to 5 for precipitation treatment, and centrifuge to obtain the clear liquid , add 25mL of buffer, 1g of indicator and 25mL of shielding agent to the clear solution; after mixing, titrate with disodium EDTA standard solution, and take the solution from purple red to sky blue as the titration end point.

[0084] Wherein, ICP-OES was used to measure the contents of metal elements in the chlorinated solution and clear liquid of the gasification slag respectively, and the specific results are shown in Table 1.

[0085] According to the titration formula, the concentration of calcium ...

Embodiment 2

[0094] This embodiment is used to illustrate the application of the method of the present invention in the mineralization of gasification slag

[0095] In the clear liquid that obtains in embodiment 1, add dropwise strong ammoniacal liquor (25-28%), maintain solution pH at about 10, pass into CO2 then 2 The gas is mineralized and then centrifuged to obtain a mineralized supernatant and the resulting carbonate product.

[0096] The chemical reactions carried out in this example are as follows:

[0097] Ca 2+ +CO 3 2- =CaCO 3 ↓

[0098] Mg 2+ +CO 3 2- =MgCO 3 ↓

[0099] Mg 2+ +2OH - =Mg(OH) 2 ↓

[0100] al 3+ +3OH - =Al(OH) 3 ↓

[0101] Use ICP-OES to measure the content of metal ions in the clear liquid after mineralization, after measuring the total amount of calcium and magnesium ions in the clear liquid after mineralization is 0.24mg / L, the carbonate product content that prepares (calculated as calcium carbonate Total) is 70.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com