A kind of perovskite solar cell with v-tin dioxide as electron transport layer and preparation method thereof

An electron transport layer and solar cell technology, applied in the field of solar cells, can solve problems such as poor electron transport characteristics, low carrier concentration, and affecting the performance of perovskite solar cells, and achieve improved electrical properties, abundant raw material reserves, improved Effects on photovoltaic response characteristics and device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

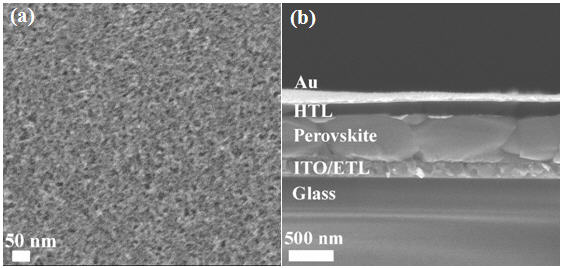

[0036] A V-SnO 2 The preparation method of the perovskite solar cell as the electron transport layer is as follows (the electron transport layer is completed in the air environment, and the rest of the preparation process is completed in the glove box):

[0037] (1) Select the deposited ITO strip electrode glass sheet and ordinary glass sheet, and wash them repeatedly with detergent to remove the oil on the surface of the glass sheet; divide the ITO conductive glass and ordinary glass into regular small pieces, such as 1 cm × 1 cm, and place them in sequence Sonicate in deionized water for 30 min, in acetone solution for 30 min, and in isopropanol solution for 30 min; dry the obtained ITO glass sheet and ordinary glass in an oven at 100 °C for 30 min to obtain clean ITO electrodes and ordinary glass sheets .

[0038] (2) Preparation of V-SnO 2 Electron transport layer:

[0039] Sequentially weigh 10 g Sn powder and 0.307 g V 2 o 5 powder (V is 4 mol% relative to the molar...

Embodiment 2

[0052] For V-SnO 2 Water dispersion, gradually increase the molar percentage of V (V relative to the molar percentage of Sn is 0, 2, 4, 6, 8, 10 mol%), after testing different V-doped molar percentages V-SnO 2 Electronic conductivity, the specific results are shown in Table 1. Table 1 shows that V doping can significantly improve its electronic conductivity.

[0053] Table 1 V-SnO obtained after introducing different mole percentages of V 2 Electronic conductivity

[0054]

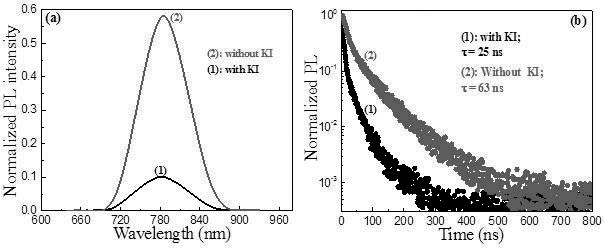

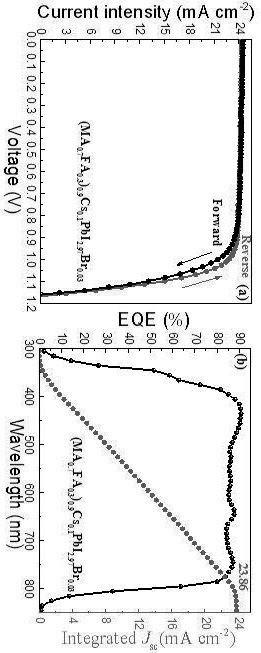

[0055] The above V-SnO with different V doping amounts 2 Preparation of V-SnO with Different Doping Amounts by Aqueous Dispersion Deposition 2 Electron transport layer, (V is successively 0, 2, 4, 6, 8, 10 mol% relative to Sn mole percentage), the photoelectric conversion efficiency of the corresponding perovskite solar cell presents a change trend that first increases and then decreases, and others are the same as in Example 1 ; The photoelectric conversion efficiency of the perovskite solar cell v...

Embodiment 3

[0057] For the introduced F127 copolymer, gradually increase the concentration of the copolymer in the perovskite precursor solution (2.0 mg / mL, 4.0 mg / mL, 6.0 mg / mL, 8.0 mg / mL, 10.0 mg / mL), the corresponding The photoelectric conversion efficiency of the perovskite solar cell also shows a trend of first increasing and then decreasing, and the others are the same as in Example 1; the photoelectric conversion efficiency of the perovskite solar cell varies with the concentration of the introduced F127 copolymer as shown in Figure 5. Depend on Figure 5 It can be seen that the photoelectric conversion efficiency shows a trend of first increasing and then decreasing. Increasing the concentration of copolymer F127 can better passivate the grain boundary defects of perovskite. The layer will be thicker. Due to the insulating properties of the copolymer F127, it will hinder the separation and transport of photogenerated charges and seriously affect the performance of the device. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com