High-temperature-resistant ultrahigh-density oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid with ultra-high density technology, applied in the field of petroleum drilling engineering, to achieve the effects of small reservoir damage, good emulsification stability, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

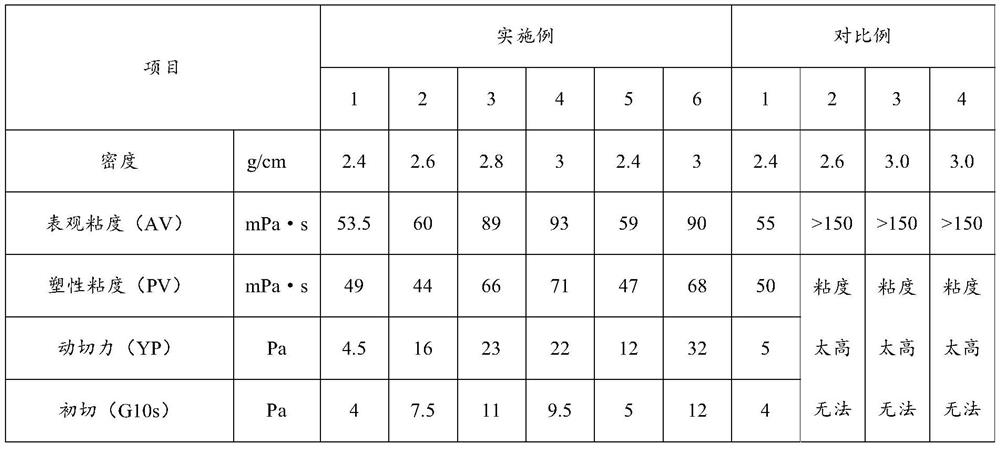

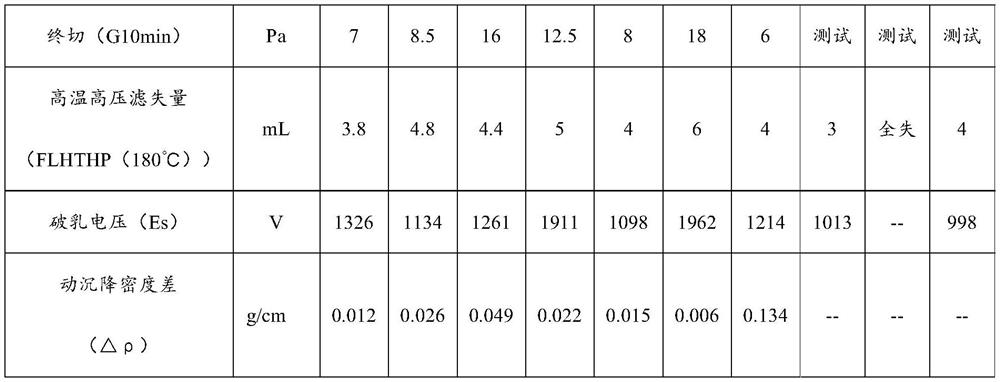

Examples

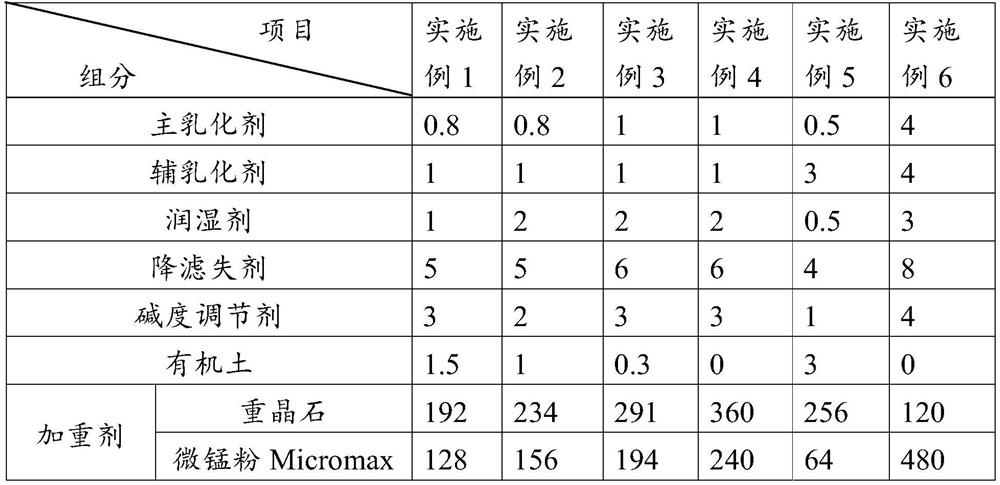

Embodiment 1

[0049] This embodiment provides a density of 2.4g / cm 3 High temperature resistant ultra-high density oil-based drilling fluid, including the following components:

[0050] The water-in-oil base liquid is composed of No. 0 diesel oil and a 25% calcium chloride aqueous solution with a volume ratio of 85:15;

[0051] Calculated per 100mL of water-in-oil base fluid, the addition amount of other components is:

[0052] PF-MOMUL 0.8g, PF-MOCOAT 1g, PF-MOWET-260 1g, modified asphalt 5g, calcium oxide 3g, organic bentonite 1.5g, barite 192g, micromanganese powder Micromax 128g.

[0053] The preparation method of the above-mentioned high-temperature-resistant ultra-high-density oil-based drilling fluid comprises the following steps:

[0054]A. Measure 255mL No. 0 diesel oil with a measuring cylinder, pour it into a high-speed mixing cup, add PF-MOMUL 2.4g, PF-MOCOAT 3g, PF-MOWET-260 3g, and stir for 4 minutes;

[0055] B. Add 45 mL of 25% calcium chloride aqueous solution and stir f...

Embodiment 2

[0060] This embodiment provides a density of 2.6g / cm 3 High temperature resistant ultra-high density oil-based drilling fluid, including the following components:

[0061] Water-in-oil base fluid, including No. 0 diesel oil with a volume ratio of 90:10 and a calcium chloride aqueous solution with a concentration of 25%;

[0062] Calculated per 100mL of water-in-oil base fluid, the addition amount of other components is:

[0063] PF-MOMUL 0.8g, PF-MOCOAT 1g, PF-MOWET-260 2g, humic acid amide 5g, calcium oxide 2g, organic bentonite 1g, barite 234g, micromanganese powder Micromax 156g.

[0064] The preparation method of the above-mentioned high-temperature-resistant ultra-high-density oil-based drilling fluid comprises the following steps:

[0065] A. Measure 270mL No. 0 diesel oil with a measuring cylinder, pour it into a high-speed mixing cup, add PF-MOMUL 2.4g, PF-MOCOAT 3g, PF-MOWET-260 6g, and stir for 5 minutes;

[0066] B. Add 30 mL of 25% calcium chloride aqueous solut...

Embodiment 3

[0071] This embodiment provides a density of 2.8g / cm 3 High temperature resistant ultra-high density oil-based drilling fluid, including the following components:

[0072] Water-in-oil base fluid, including No. 0 diesel oil with a volume ratio of 90:10 and a calcium chloride aqueous solution with a concentration of 25%;

[0073] Calculated per 100mL of water-in-oil base fluid, the addition amount of other components is:

[0074] PF-MOMUL 1g, PF-MOCOAT 1g, PF-MOWET-260 2g, modified asphalt 6g, calcium oxide 3g, organic bentonite 0.3g, barite 291g, micromanganese powder Micromax 194g.

[0075] The preparation method of the above-mentioned high-temperature-resistant ultra-high-density oil-based drilling fluid comprises the following steps:

[0076] A. Measure 270mL No. 0 diesel oil with a measuring cylinder, pour it into a high-speed mixing cup, add PF-MOMUL 3g, PF-MOCOAT 3g, PF-MOWET-260 6g, and stir for 6 minutes;

[0077] B. Add 30mL of 25% calcium chloride aqueous solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com