Caprolactam extract washing tower, system and process

A caprolactam and extraction liquid technology, applied in the field of caprolactam extraction liquid washing towers, can solve the problems affecting extraction effect and product quality, high conductivity of caprolactam aqueous solution, equipment corrosion, etc., and achieves the effects of large load elasticity, reduced electrical conductivity, and reduced corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] The third embodiment of the present invention provides a caprolactam extract washing process. The caprolactam extract washing tower is provided, and the caprolactam solution after neutralization and crystallization is subjected to benzene extraction, and the caprolactam extract after benzene extraction enters the caprolactam extract for washing The tower is washed with water to obtain the washed caprolactam extract, and the washed caprolactam extract is back-extracted.

[0031] In some examples of this embodiment, the water feed pressure of the water phase feed distributor in the caprolactam extract washing tower is 0.5-0.6 Mpa.

[0032] In some examples of this embodiment, the volume ratio of the washing water in the caprolactam extract washing tower to the caprolactam extract is 0.01˜0.05:1. According to the characteristics of caprolactam, it is both soluble in water and soluble in benzene (the solubility in water is slightly greater than that of benzene), but in the ...

Embodiment 1

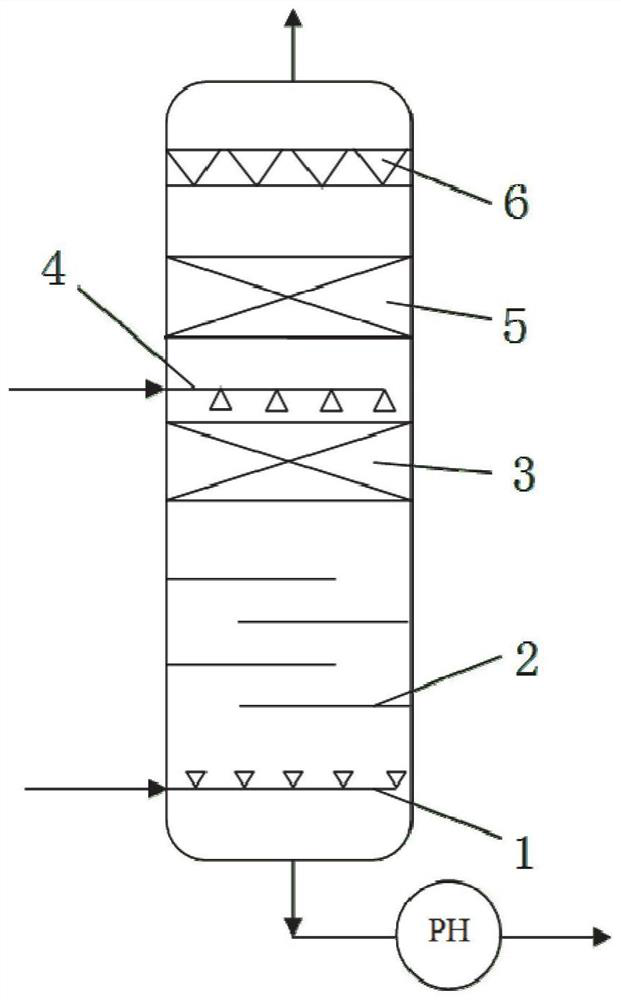

[0035] A caprolactam extract scrubber, such as figure 1 As shown, it includes a vertical tower body, and the tower body includes oil phase feed distributor 1, several sieve plates 2, random packing layer 3, water phase feed distributor 4, structured packing layer 5 and Wire mesh coalescer6.

[0036] The outlet of the oil phase feed distributor 1 is set upward, and the water outlet hole of the water phase feed distributor 4 is set downward. The water phase feed distributor 4 forms a "feng"-shaped structure by the main water pipe and the branch water pipe. The branch water pipe A number of water outlet holes with a diameter of 1-2mm are opened, the water phase outlet is installed at the bottom of the tower body, the online pH meter is installed at the water phase outlet, and the oil phase outlet is installed at the top of the tower body. 38# random saddle ring random packing is used in the random packing layer 3.

[0037] The caprolactam extraction liquid washing tower is inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com