Method for preparing magnetic zinc cadmium sulfide composite photocatalyst

A technology of zinc cadmium sulfide and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as difficulty in recycling, complex preparation process of zinc cadmium sulfide, etc., and achieve less equipment and high energy efficiency. The effect of low consumption and simple preparation and operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

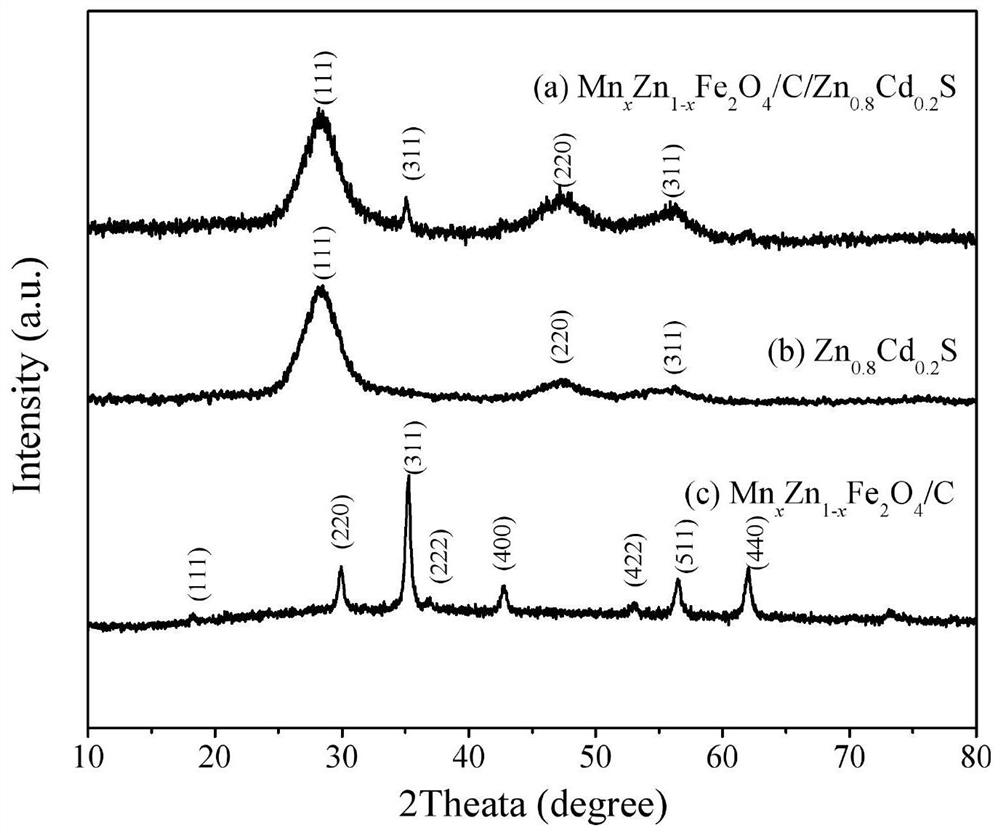

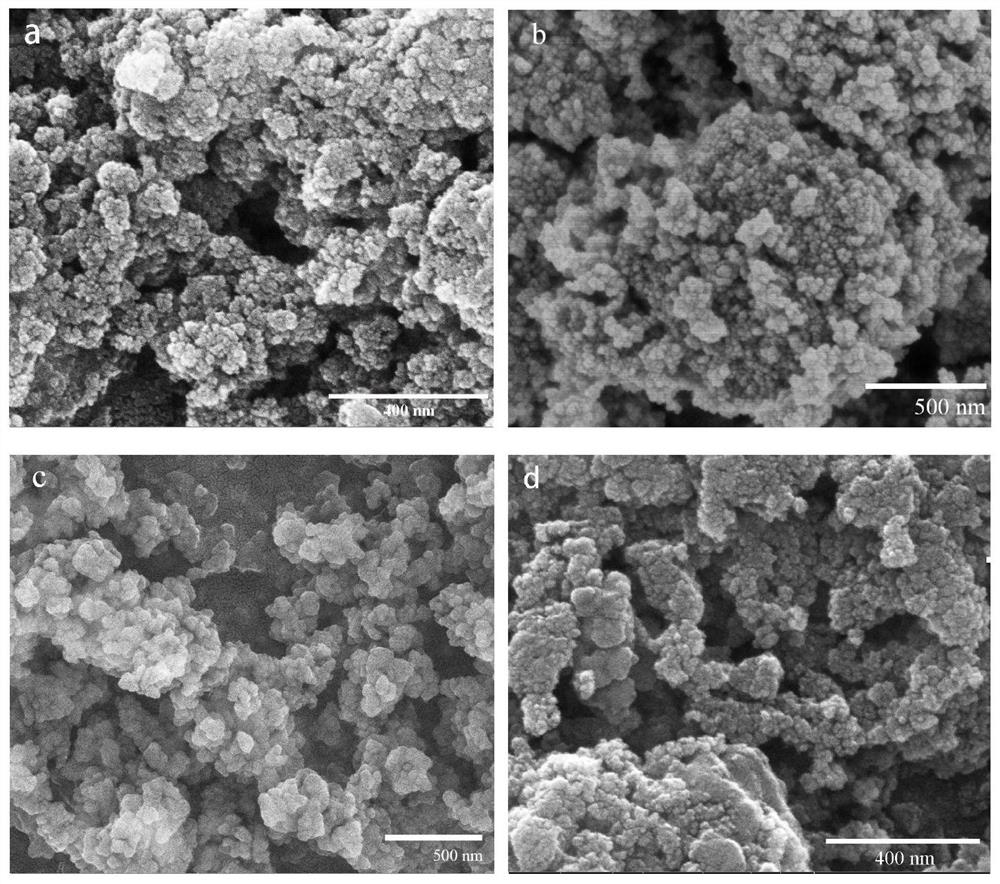

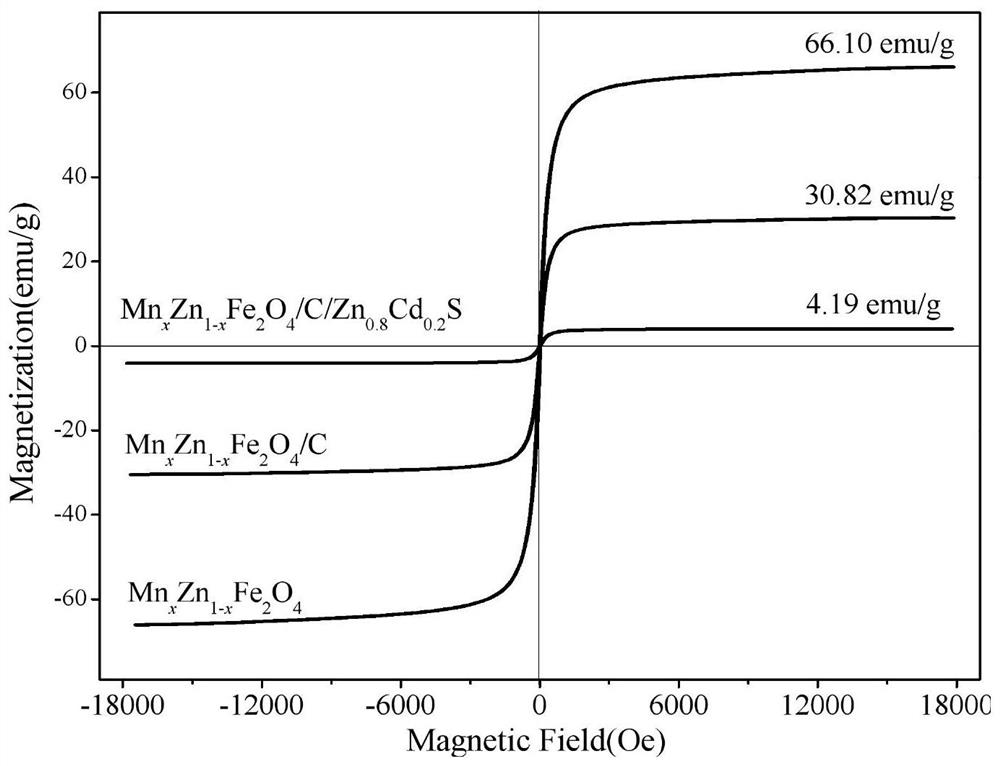

[0021] A magnetic zinc cadmium sulfide composite photocatalyst (Mn x Zn 1-x Fe 2 O 4 / C / Zn 0.8 Cd 0.2 The preparation method of S), the specific steps are as follows:

[0022] (1) Mn x Zn 1-x Fe 2 O 4 / C preparation

[0023] According to the molar ratio n(MnO):n(ZnO):n(Fe 2 O 3 )=32.8:13.3:53.9, respectively weigh a certain amount of MnSO 4 ·H 2 O, ZnSO 4 ·7H 2 O and Fe 2 (SO 4 ) 3 , Add a certain amount of deionized water and stir well to obtain a uniform mixed solution; weigh a certain amount of NaOH as a precipitant to prepare a NaOH solution with a concentration of 2mol / L; slowly drop the NaOH solution into the mixed solution under magnetic stirring , When there is brown flocculent precipitate in the solution, quickly add NaOH solution dropwise, adjust the pH to 13, and continue to stir for 20 minutes; transfer the stirred solution into a 100 mL reactor, and heat it in an oven at 200°C for 5 hours; After the hydrothermal reaction is completed, take it out and cool it to room te...

Embodiment 2

[0028] A magnetic zinc cadmium sulfide composite photocatalyst (Mn x Zn 1-x Fe 2 O 4 / C / Zn 0.8 Cd 0.2 The preparation method of S), the specific steps are as follows:

[0029] (1) Mn x Zn 1-x Fe 2 O 4 / C preparation

[0030] Same as in Example 1 (1).

[0031] (2) Magnetic composite photocatalyst Mn x Zn 1-x Fe 2 O 4 / C / Zn 0.8 Cd 0.2 Preparation of S

[0032] According to the molar ratio n(Zn 2+ ):n(Cd 2+ ):n(S 2- )=0.8:0.2:1.25, weigh an appropriate amount of Zn(Ac) 2 ·2H 2 O and Cd(Ac) 2 ·2H 2 O, dissolve into 40mL deionized water by ultrasonic, add and theoretically generate Zn 0.8 Cd 0.2 Mn with S mass ratio of 10:100 x Zn 1-x Fe 2 O 4 / C, mechanically stirred for 30min to obtain suspension A; weigh out 0.9g of Na 2 S·9H 2 O ultrasonically dissolved in 40mL deionized water to obtain solution B; under continuous stirring, use a glue-tip dropper to drop solution B into suspension A at a certain rate, continue to stir for a period of time and then leave it for 24 hours; Centrifuge at ...

Embodiment 3

[0034] A magnetic zinc cadmium sulfide composite photocatalyst (Mn x Zn 1-x Fe 2 O 4 / C / Zn 0.8 Cd 0.2 The preparation method of S), the specific steps are as follows:

[0035] (1) Mn x Zn 1-x Fe 2 O 4 / C preparation

[0036] Same as in Example 1 (1).

[0037] (2) Magnetic composite photocatalyst Mn x Zn 1-x Fe 2 O 4 / C / Zn 0.8 Cd 0.2 Preparation of S

[0038] According to the molar ratio n(Zn 2+ ):n(Cd 2+ ):n(S 2- )=0.8:0.2:1.25, weigh an appropriate amount of Zn(Ac) 2 ·2H 2 O and Cd(Ac) 2 ·2H 2 O, dissolve into 40mL deionized water by ultrasonic, add and theoretically generate Zn 0.8 Cd 0.2 Mn with S mass ratio of 15:100 x Zn 1-x Fe 2 O 4 / C, mechanically stirred for 30min to obtain suspension A; weigh out 0.9g of Na 2 S·9H 2 O ultrasonically dissolved in 40mL deionized water to obtain solution B; under continuous stirring, use a glue-tip dropper to drop solution B into suspension A at a certain rate, continue to stir for a period of time and then leave it for 24 hours; Centrifuge at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com