Drum pavement simulation material with multilayer composite structure and preparation method thereof

A multi-layer composite and simulation technology, which is applied in the field of simulated pavement materials, can solve the problems of only its shape and lack of actual pavement force, etc., and achieve the effect of reducing waste, preventing distortion or even falling off, and combining tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

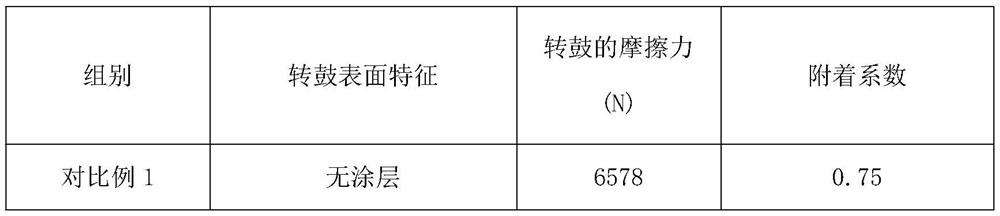

Examples

Embodiment 1

[0028] A drum pavement simulation material with a multi-layer composite structure, comprising a surface layer, an intermediate layer and a bottom layer, the surface layer is a carbon steel substrate surface sprayed with a nickel-containing tungsten carbide coating, the intermediate layer is a rubber layer, and the The bottom layer is an ordinary carbon steel thin layer.

[0029] The thickness of each layer of the simulation material is: carbon steel substrate 2.5mm, nickel-containing tungsten carbide coating 0.2mm, rubber layer 3.0mm, ordinary carbon steel thin layer 1.0mm.

[0030] The rubber layer is composed of the following raw materials in parts by weight: 100.0 parts of fluororubber, 5.0 parts of aromatic oil, 10.0 parts of carbon black, 5.0 parts of zinc oxide, 1.5 parts of peroxide curing agent, 1681.5 parts of antioxidant, coupling agent Silane 2.0 parts.

Embodiment 2

[0032] A drum pavement simulation material with a multi-layer composite structure, comprising a surface layer, an intermediate layer and a bottom layer, the surface layer is a carbon steel base material surface sprayed with a 7Cr13 martensitic stainless steel coating, the intermediate layer is a rubber layer, and the The bottom layer is an ordinary carbon steel thin layer.

[0033] The thickness of each layer of the simulation material is: carbon steel substrate 5.5mm, 7Cr13 martensitic stainless steel coating 0.6mm, rubber layer 8.0mm, ordinary carbon steel thin layer 3.0mm.

[0034] The rubber layer is composed of the following raw materials in parts by weight: 90.0 parts of acrylate rubber, 1.0 part of naphthenic oil, 1.0 part of calcium carbonate, 1.0 part of carbon nanotube, 0.5 part of metal oxide vulcanizing agent, 40100.1 parts of anti-aging agent, even Linking agent titanate 0.1 part.

Embodiment 3

[0036] A drum pavement simulation material with a multi-layer composite structure, comprising a surface layer, an intermediate layer and a bottom layer, the surface layer is a carbon steel substrate surface sprayed with a nickel-containing tungsten carbide coating, the intermediate layer is a rubber layer, and the The bottom layer is an ordinary carbon steel thin layer.

[0037] The thickness of each layer of the simulation material is: carbon steel base material 4mm, nickel-containing tungsten carbide coating 0.22mm, rubber layer 5.0mm, ordinary carbon steel thin layer 2.0mm.

[0038] The rubber layer is composed of the following raw materials in parts by weight: 120.0 parts of silicone rubber, 20.0 parts of white oil, 70.0 parts of kaolin, 30.0 parts of silicon carbide, 3.0 parts of resin vulcanizing agent, 5.0 parts of anti-aging agent MB, 5.0 parts of coupling agent silane share.

[0039] The preparation method of the drum pavement simulation material of a kind of multi-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com