Reactive moisture-curable polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and moisture-curing technology, applied in the field of polymer chemistry, can solve the problems of high polyether content, unfavorable bonding performance, and insufficient moisture permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1

[0076] The ratio of raw materials of Examples 1-4 and Comparative Example 1 is shown in Table 1.

[0077] The raw material of table 1 embodiment 1-4 and comparative example 1 and its mass proportioning

[0078] Raw materials (parts by mass) Example 1 Example 2 Example 3 Example 4 Comparative example 1 Isocyanate 1A 24 20 20 27 28 Polyether polyol 2A 25 Polyether polyol 2B 38 18 43 41 Polyether polyol 2C 38 Polyether polyol 2D 3 9 4 Polyester polyol 3A 2 Polyester polyol 3B 20 Polyester polyol 3C 20 20 12 Polyester polyol 3D 11.8 10 Polyester polyol 3E 14.5 14.5 10 Polyester polyol 3F 20 Compound 4A containing long chain aliphatic hydrocarbon 0.5 0.4 0.5 Compound 4B containing long chain aliphatic hydrocarbon 5 Hydroxyalkyl modified silicone oil 5A 0.2 0.1 0.5 NCO(wt%) 2.91 2.74...

experiment example

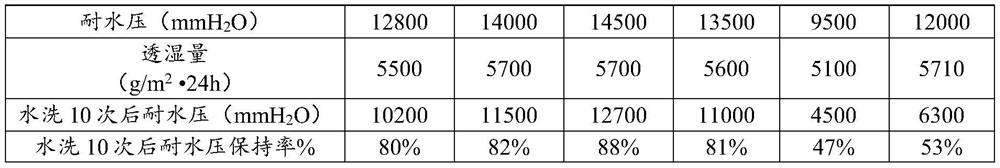

[0082] The reactive moisture-curing polyurethane hot-melt adhesive PUR sample prepared by Examples 1-4 and Comparative Example 1, the commercially available product PU-1 of Comparative Example 2 were used respectively to attach cloth and TPU film, wherein the cloth was a grade 5 waterproof fabric, The TPU film is a medium-permeable film (according to the ASTM E96BW standard, the moisture permeability is 8000), and the compounding is completed at a temperature of 23°C and a humidity of 50% and aged for 24 hours, and then the properties are tested according to the following methods.

[0083] Water pressure resistance test method: According to the ISO 811-2018 standard, the composite cloth film samples prepared above were respectively fixed on a standard instrument, and pressurized at a constant speed until 3 water drops appeared or the film was damaged, and the water pressure at this time was recorded. The water pressure is the water pressure resistance value of the sample (mmH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com