Karst tunnel bottom filling beaded type karst cave steel pipe pile grouting hole forming method

A technology of steel pipe piles and beaded type, which is applied to drilling equipment and methods, tunnels, earthwork drilling and mining, etc. It can solve the problems of increased difficulty in steel pipe pile construction, slow construction progress, and difficulty in pulling out drill bits, and achieve economic benefits And the effect of obvious social benefits, easy installation and removal, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

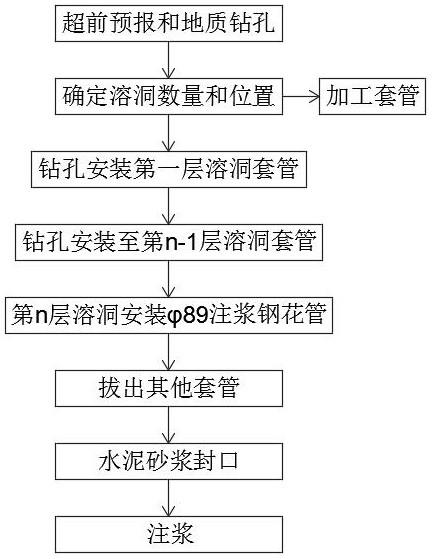

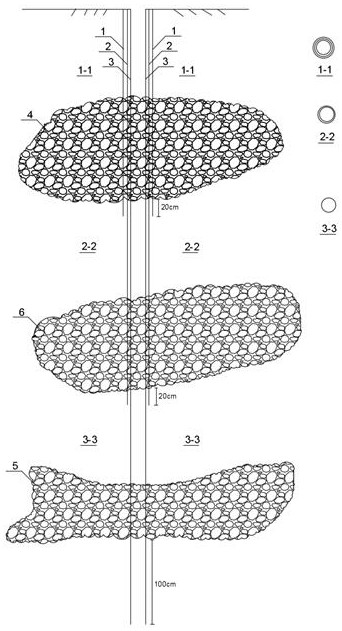

[0052] specific reference figure 2Before construction, use geological radar to detect beaded karst at the bottom of the tunnel. For areas with definite karst, use geological drilling to detect and confirm the distribution of beaded karst, including the number of caves, cave size, cave location, and cave filling. ;

[0053] Further, according to the distribution of beaded karst, determine the grouting parameters of the steel pipe pile, including the grouting depth, the number and length of the grouting hole passing through the karst cave;

[0054] Further, according to the depth of the grouting hole of the steel pipe pile and the number of cross-beaded karst caves, the number of casings and the different diameters of casings are determined, preferably casing 1 with a diameter of ∅146, casing 2 with a diameter of ∅127, Casing 3 with a caliber of ∅110, the casings of different calibers are divided into sections according to the drilling depth, and each section is threaded for e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com