Organic nano negative electrode based on intercalated pseudocapacitor and preparation method and application of negative electrode

A pseudocapacitive and organic technology, applied in the field of energy devices, to achieve good electronic conductivity, improved reversible capacity, and high reversible capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides an organic nano-anode based on an intercalated pseudocapacitance and its preparation method and application, specifically:

[0045] (1) Preparation of 2,2'-bipyridyl-4,4'-dicarboxylic acid electrode and performance test of lithium ion battery

[0046] (1) Place the 2,2'-bipyridyl-4,4'-dicarboxylic acid material in a blast drying oven and dry at 120°C for 8 hours;

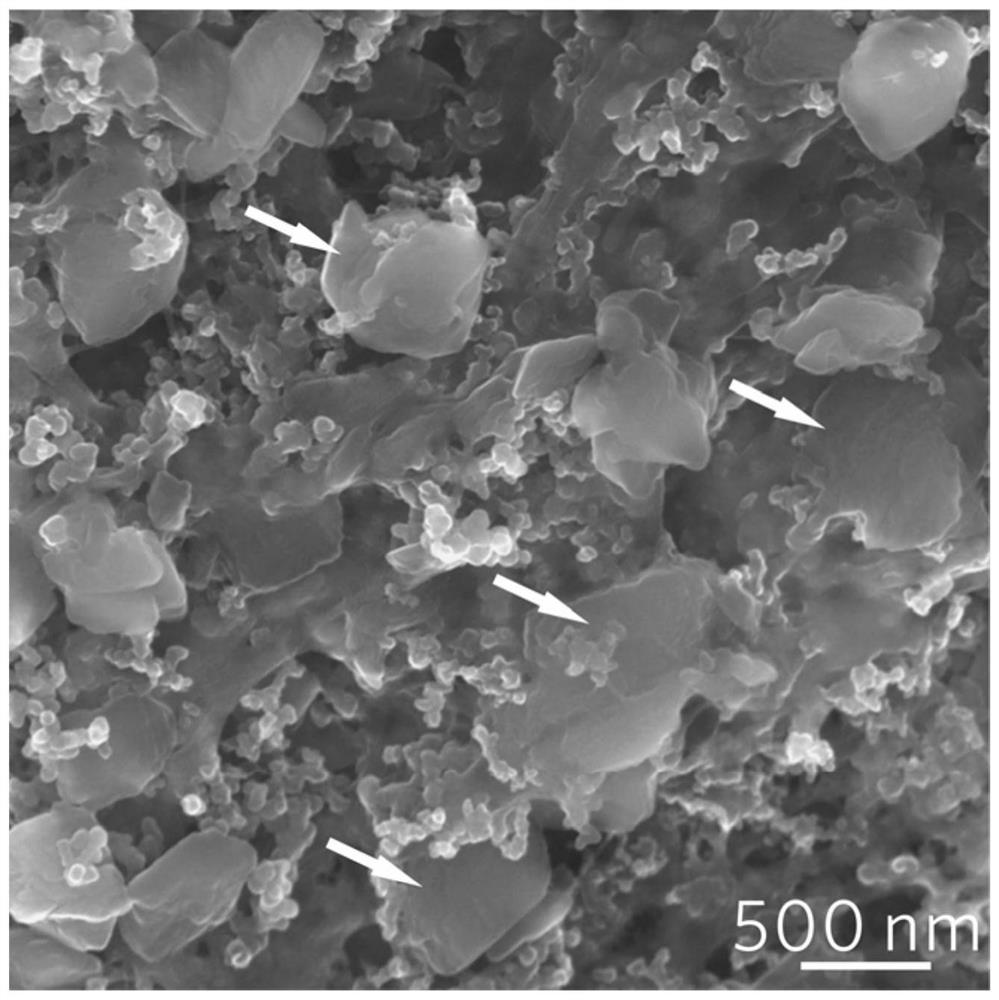

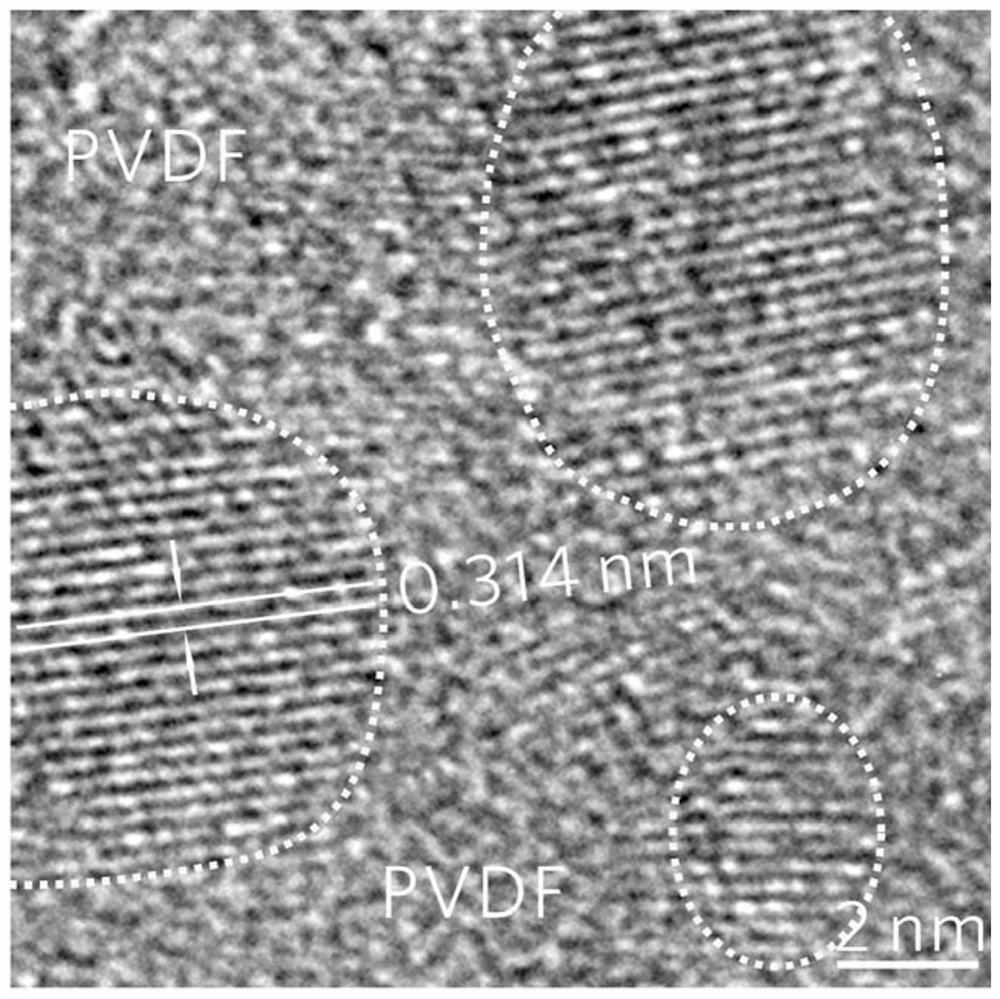

[0047] (2) At room temperature, weigh 0.5g 2,2'-bipyridine-4,4'-dicarboxylic acid, 0.4g conductive carbon black and 0.1g binder (polyvinylidene fluoride, commercially available), grind 10 minutes, then add 20ml of solvent (N-methylpyrrolidone), stir well, grind by high-energy ball mill for 2 hours, and then evenly coat on copper foil;

[0048] (3) Drying at 60°C for 3 hours, followed by vacuum drying at 120°C to obtain 2,2'-bipyridyl-4,4'-dicarboxylic acid pole pieces;

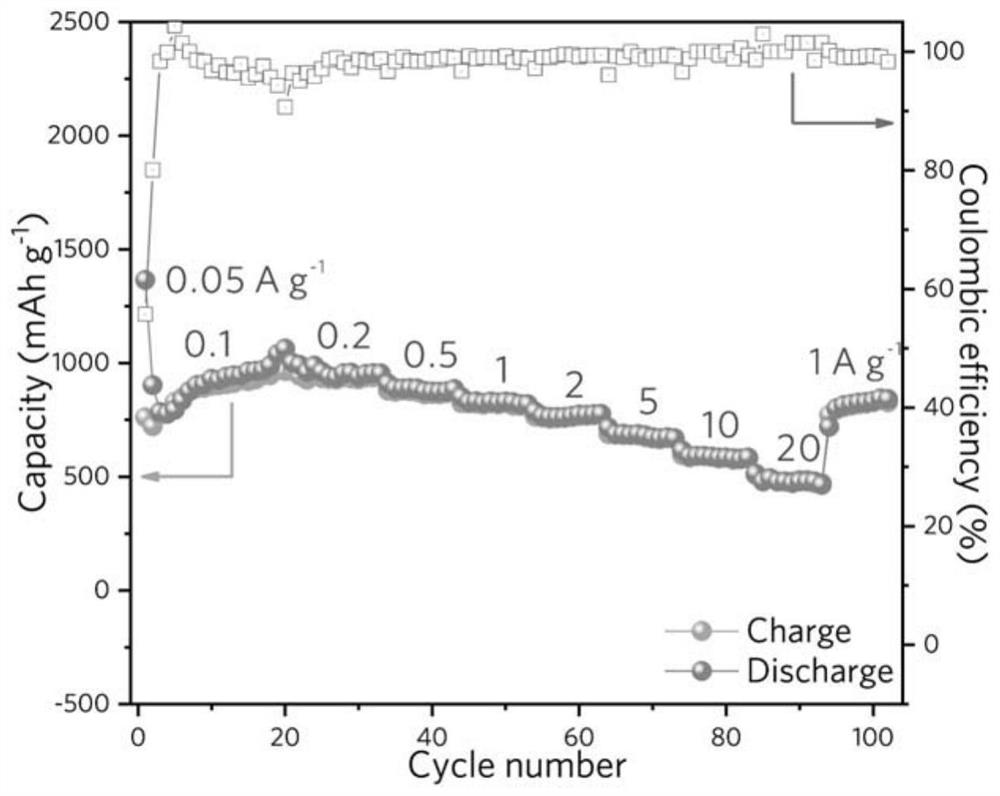

[0049] (4) Use the 2,2'-bipyridyl-4,4'-dicarboxylic acid electrode obtained in step (3) as the negative electrode...

Embodiment 2

[0066] This embodiment provides an organic nano negative electrode based on an intercalation type pseudocapacitance and its preparation method and application, which is basically the same as that in Example 1, except that the organic electrode material is fumaric acid, and its full battery Table 1 shows the maximum energy density, maximum power density and battery voltage data.

Embodiment 3

[0068] This embodiment provides an organic nano negative electrode based on an intercalation type pseudocapacitance and its preparation method and application, which is basically the same as that in Example 1, except that the organic electrode material is sodium citrate, and the maximum capacity of the full battery is The energy density, maximum power density and battery voltage data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com