Water-based cleaning agent for liquid crystal cleaning

A water-based cleaning agent and liquid crystal technology, applied in the field of microelectronic materials, can solve the problems of poor slit permeability of liquid crystal cells, strong dependence on ultrasonic emulsification, poor cleaning effect, etc., and achieve good biodegradability, good emulsification stability, Increase the effect of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

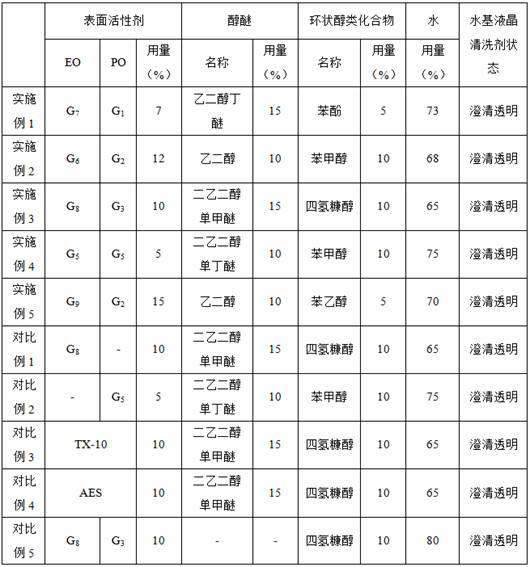

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. The exemplary embodiments and descriptions of the present invention are only used to explain the present invention, and are not intended to limit the present invention.

[0029] (1) Synthesis of Intermediate I

[0030] Add 5 mol γ-aminopropylmethyldiethoxysilane 1, 25 mol hexamethyldisiloxane 2 and 0.5 mol potassium hydroxide into a three-necked flask, raise the temperature to 90°C under the protection of nitrogen, and reflux reaction 2 Hour; After reaction finishes, underpressure distillation is to constant weight, obtains intermediate I; Its reaction flow formula is as follows:

[0031] ;

[0032] (2) Synthesis of Intermediate II

[0033] In a three-neck flask equipped with a stirring and reflux device, add 5 mol of intermediate I, and dropwise add 5.5 mol of allyl polyoxyethylene polyoxypr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com