Cyanide-free gold electroplating solution and electroplating process thereof

A cyanide-free gold plating and electroplating solution technology, which is applied in the field of electroplating, can solve problems such as the stability of the plating solution or the lack of coating quality, and restrictions on popularization and application, and achieve the effects of improving electroplating efficiency, stability, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of cyanide-free gold plating electroplating solution, described electroplating solution comprises main complexing agent 30g / L, conductive salt 10g / L, carbonate 20g / L, other additive 0.1g / L, tetrachloroauric acid 1g / L, stable Agent 0.1g / L; Described stabilizer is prepared by following method:

[0033] (1) Weigh 9g of ethylenediaminetetraacetic acid, 20mL of pyridine, and 15mL of acetic anhydride and place them in a flask in sequence. The reaction temperature is 65°C, and they are stirred for 24 hours under a nitrogen atmosphere. Washing, then drying in a vacuum oven, the product is stored in a desiccator;

[0034] (2) Take 5g of chitosan and dissolve it in acetic acid with a volume fraction of 3%, weigh 5g of the product obtained in step (1) and add it to methanol, then place the two in a flask and react with mechanical stirring at 30°C After 24 hours of reaction, wash with 100 mL of 0.1 mol / L NaOH solution, distilled water, 0.1 mol / L HCl solution, distilled wate...

Embodiment 2

[0053] A kind of cyanide-free gold plating electroplating solution, described electroplating solution comprises main complexing agent 80g / L, conductive salt 90g / L, carbonate 60g / L, other additive 8g / L, tetrachloroauric acid 10g / L, stabilizer 0.5g / L; Described stabilizer is prepared by following method:

[0054] (1) Weigh 9g of ethylenediaminetetraacetic acid, 20mL of pyridine, and 15mL of acetic anhydride and place them in a flask in sequence. The reaction temperature is 65°C, and they are stirred for 24 hours under a nitrogen atmosphere. Washing, then drying in a vacuum oven, the product is stored in a desiccator;

[0055] (2) Take 5g of chitosan and dissolve it in acetic acid with a volume fraction of 3%, weigh 5g of the product obtained in step (1) and add it to methanol, then place the two in a flask and react with mechanical stirring at 30°C After 24 hours of reaction, wash with 100 mL of 0.1 mol / L NaOH solution, distilled water, 0.1 mol / L HCl solution, distilled water, ...

Embodiment 3

[0075] A kind of cyanide-free gold plating electroplating solution, described electroplating solution comprises main complexing agent 80g / L, conductive salt 90g / L, carbonate 60g / L, other additive 8g / L, tetrachloroauric acid 10g / L, stabilizer 0.5g / L; Described stabilizer is prepared by following method:

[0076] (1) Weigh 9g of ethylenediaminetetraacetic acid, 20mL of pyridine, and 15mL of acetic anhydride and place them in a flask in sequence. The reaction temperature is 65°C, and they are stirred for 24 hours under a nitrogen atmosphere. Washing, then drying in a vacuum oven, the product is stored in a desiccator;

[0077] (2) Take 5g of chitosan and dissolve it in acetic acid with a volume fraction of 3%, weigh 5g of the product obtained in step (1) and add it to methanol, then place the two in a flask and react with mechanical stirring at 30°C After 24 hours of reaction, wash with 100 mL of 0.1 mol / L NaOH solution, distilled water, 0.1 mol / L HCL solution, distilled water, ...

PUM

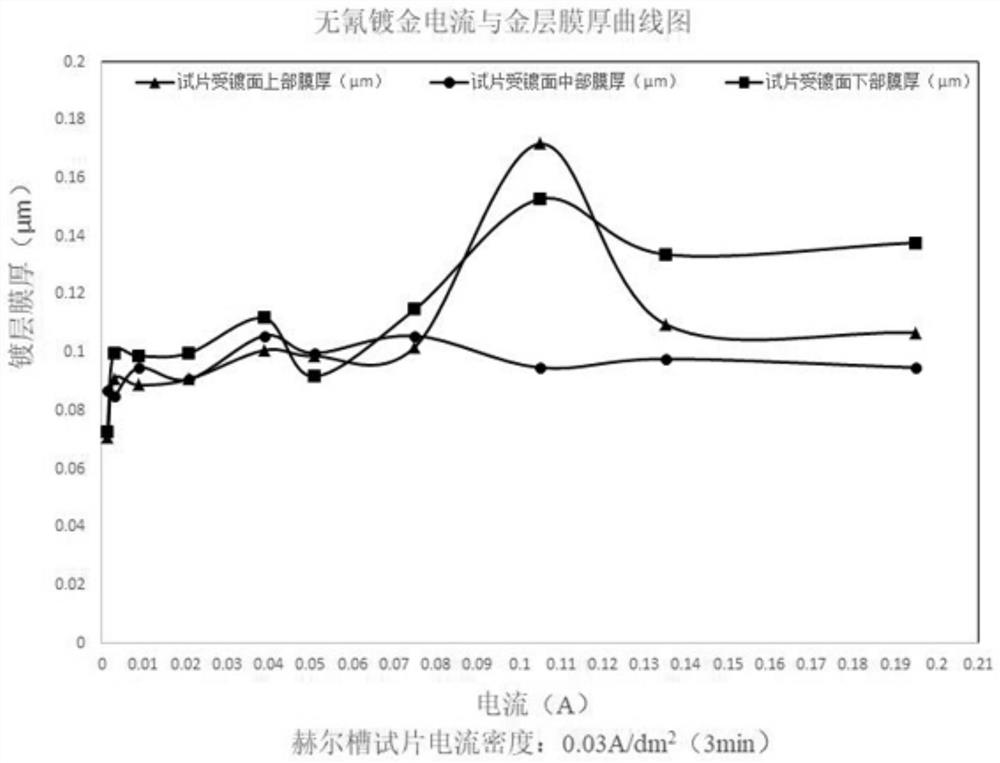

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com