Processing method of olive powder used in diversified ways

A processing method and technology of olive powder, applied in application, food preservation, fruit and vegetable preservation, etc., can solve the problems of unsuitable materials with high solid content, high cellulose content of fresh olive fruit, low raw material utilization rate, etc., and achieve product additional The value and economic benefits are improved, the quality of finished products is stable, and the effect of high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

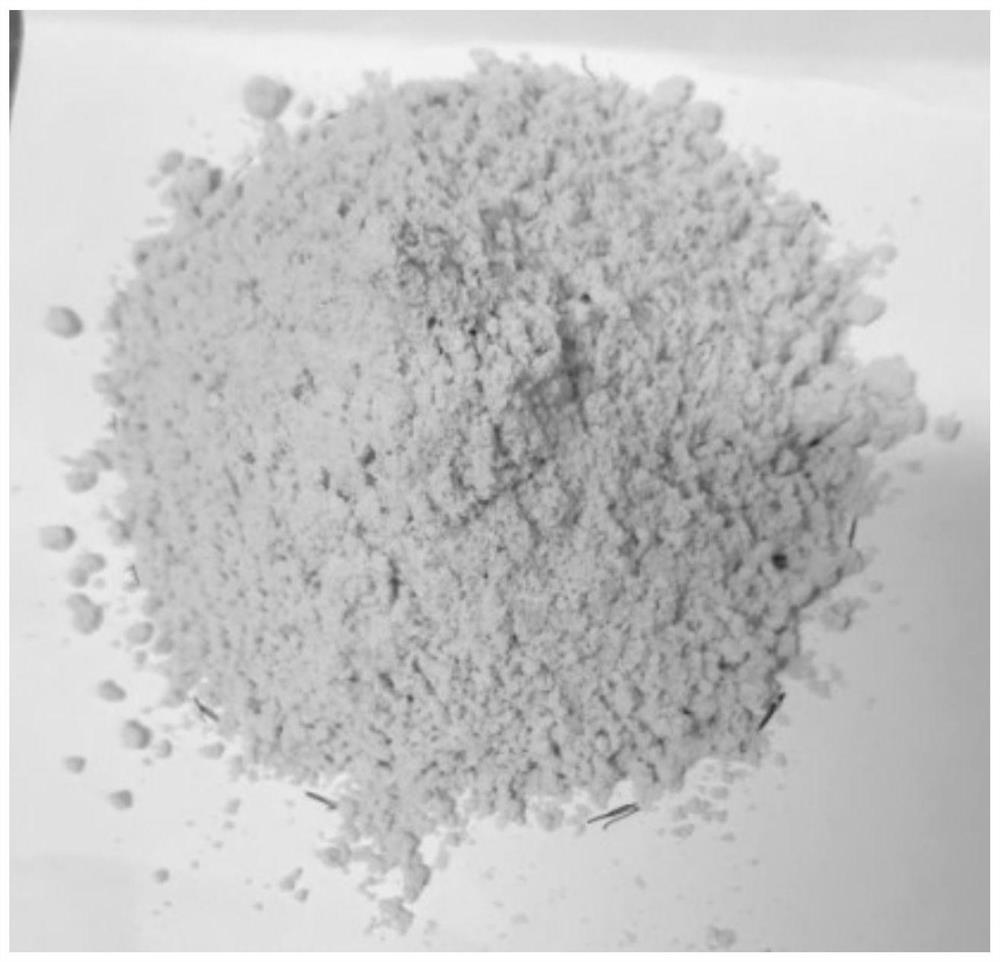

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

[0020] The processing method of the present invention's multiple utilization of olive powder specifically comprises the following steps:

[0021] (1) Fruit selection and cleaning: select olives that are fresh, free from drying shrinkage, brown staining, mechanical damage, disease and insect pests, and rotten, and use running water to clean fresh fruits and drain them;

[0022] (2) Color protection: Put the fresh fruit in boiling water at 100°C for 1 minute, then cool;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com