Method for brewing wine by fermented wine steaming

A technology for fermenting raw materials and beverages, applied in the field of winemaking, can solve the problems of not being able to ensure sufficient separation of starch and sugars, not being able to control the fermentation temperature well, and not being able to have health care effects, etc., so as to improve immunity and improve medicinal value. , improve the effect of full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

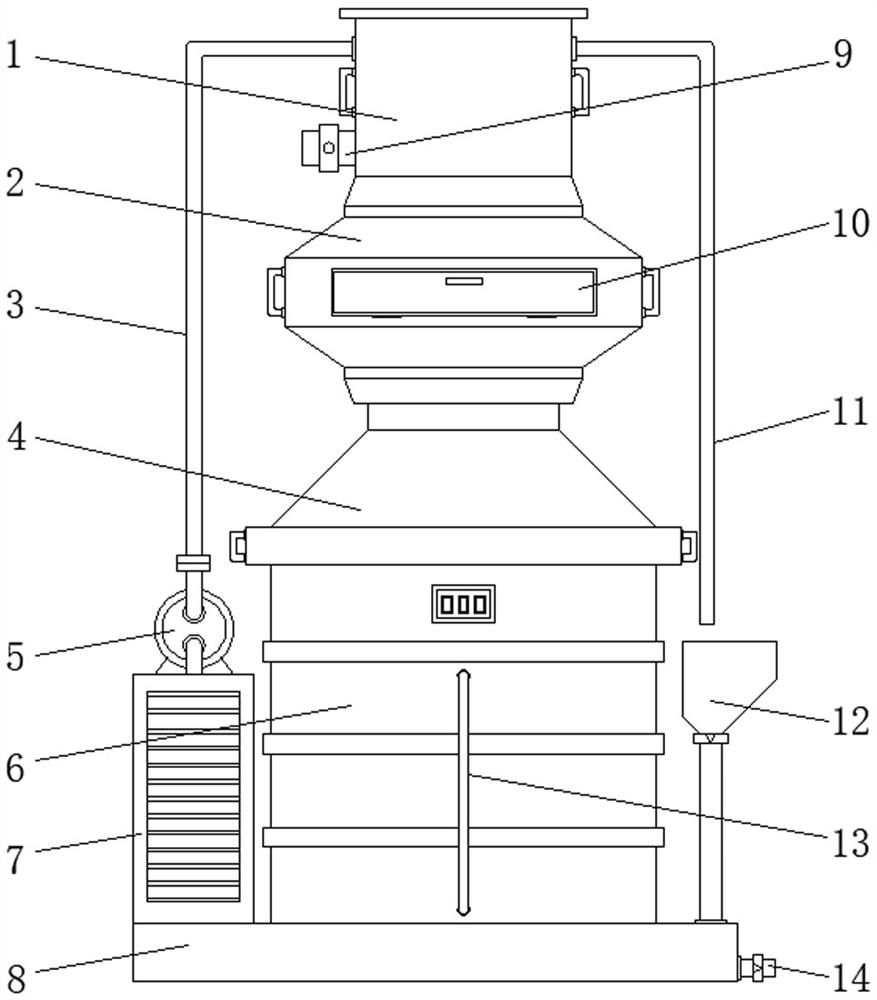

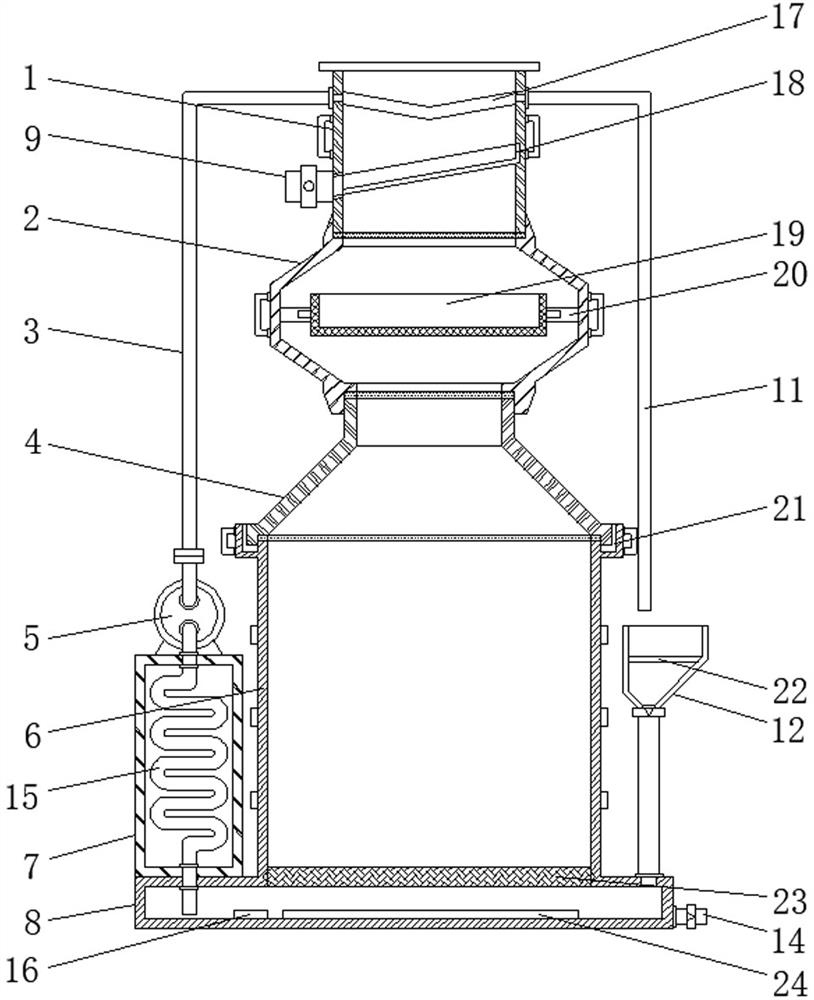

Image

Examples

Embodiment 1

[0035] A winemaking method for fermented wine, comprising the steps of:

[0036] Step 1. Select fermentation raw materials: take sorghum with full grains as fermentation raw materials, wash the grains with clean water 3 times and sieve out the water, then grind the washed grains and pass through a 30-mesh sieve to obtain clean Grain scraps, spare;

[0037] Step 2, select fermented herbal medicine: take washed and dried astragalus, black wolfberry and honeysuckle, weigh and mix them according to the ratio of 5:3:2, break them up, pass through a 50-mesh sieve to obtain herbal medicine granules, and set aside;

[0038] Step 3, steaming of raw materials and herbs: Put the grain scraps in step 1 into a cooking pot, inject an appropriate amount of water and cook for 20 minutes, then drain excess water, the weight ratio of grain scraps to cooking water is 1:1.5, and then Pour the herb granules prepared in step 2 into another steamer, inject an appropriate amount of water and cook fo...

Embodiment 2

[0045] A fermented brewing method for distilling wine. The difference between this example and Example 1 is that in step 1, full-grained peas and barley are used as fermentation raw materials; in step 2, washed and dried lotus seeds, lilies and yams are used. As herbal medicine, lotus seeds, lilies and yams are weighed in a ratio of 2:2:6; in step 3, the cooking time of grain scraps is 25 minutes, and the cooking time of herbal medicine granules is 18 minutes, and the water content is 18wt%. Mature grain scraps and 48wt% pasty herbal medicine with a water content of 48%; the temperature of the cooled grain scraps in step 4 is 33°C, the temperature of the cooled pasty herbs is 28°C, and the fermentation time of the grain scraps is 9 days. The fermentation time of the pasty herbal medicine is 13 days; in step 5, when the grain scraps are distilled at high temperature, keep the water temperature at 97°C during distillation. After putting the pasty herbal medicine into the steamer,...

Embodiment 3

[0049] A method for brewing fermented wine. The difference between this embodiment and Embodiment 1 is that in step 1, full-grained wheat and small yellow rice are used as fermentation raw materials; in step 2, washed and dried black wolfberry, Honeysuckle and mulberry leaves are used as herbal medicines, and black wolfberry, honeysuckle and mulberry leaves are weighed according to the ratio of 2:1:7; the cooking time of grain scraps in step 3 is 30 minutes, and the cooking time of herbal medicine particles is 20 minutes, and the obtained Moisture content is 15wt% cooked grain scraps and 45wt% pasty herbal medicine with water content; the grain scrap temperature after cooling in step 4 is 35 ℃, the pasty herbal medicine temperature after cooling is 30 ℃, the grain scrap The fermentation time is 10 days, and the fermentation time of the pasty herbs is 15 days; Step 5, when the Chinese grain scraps are distilled at high temperature, keep the water temperature at 98°C during disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com