GaN-based vertical structure micro-cavity Micro-LED based on electroplating technology and preparation method thereof

A vertical structure and technology technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of limited bandwidth and slow luminous rate, and achieve the effect of improving brightness, fast luminous speed, and improving the directionality of front light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The structure of the vertical microcavity GaN-based Micro-LED of the present invention is as follows: Figure 9 As shown, it includes a Micro-LED chip and a substrate 7, and the Micro-LED chip is located on the substrate 7; the Micro-LED chip includes a dielectric film 10, an n-GaN layer 3, an MQW layer 4, a p -GaN layer 5 and reflector electrode 6, wherein reflector electrode 6 and substrate seven 7 join; The width of the bottom seven 7 is equal; the width of the dielectric film 10 is smaller than the n-GaN layer 3, and the mesa 11 will leak out on both sides of the n-GaN layer; the width of the mirror electrode is larger than the n-GaN layer 3, MQW layer 4, p -GaN layer 5, the mesa 11 will leak out on both sides of the mirror electrode 6, and the n-GaN layer 3, the MQW layer 4, and the p-GaN layer 5 will leak out two sidewalls; there is a passivation layer on the mesa 11 and the sidewall 8; The shape of the passivation layer 8 is a right-angled Z-shape; the passivati...

Embodiment 2

[0048] The preparation method of the vertical microcavity GaN-based Micro-LED provided in this embodiment includes the following steps:

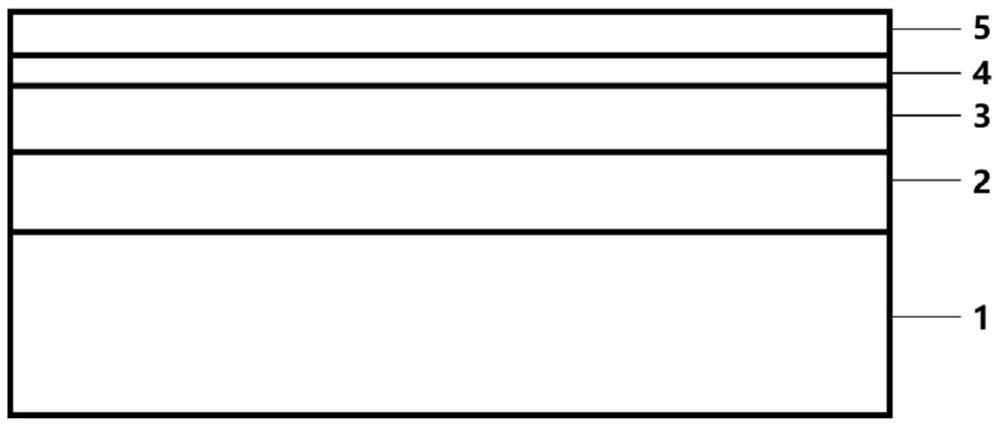

[0049] (1) On the (0001) plane sapphire (substrate 1), grow u-GaN layer 2 (5 μm in thickness), n-GaN layer 3 (5 μm in thickness), [InGaN (2nm) / GaN (10nm)] 8 MQW (quantum well) layer 4 (thickness is 96nm), p-GaN layer 5 (thickness is 100nm), obtains LED epitaxy material, and its luminescence wavelength is determined by the In composition in MQW (quantum well) layer 4, in this implementation In the example, the emission wavelength is 460nm. The structure of the obtained LED epitaxial material in step (1) is as follows: figure 1 shown.

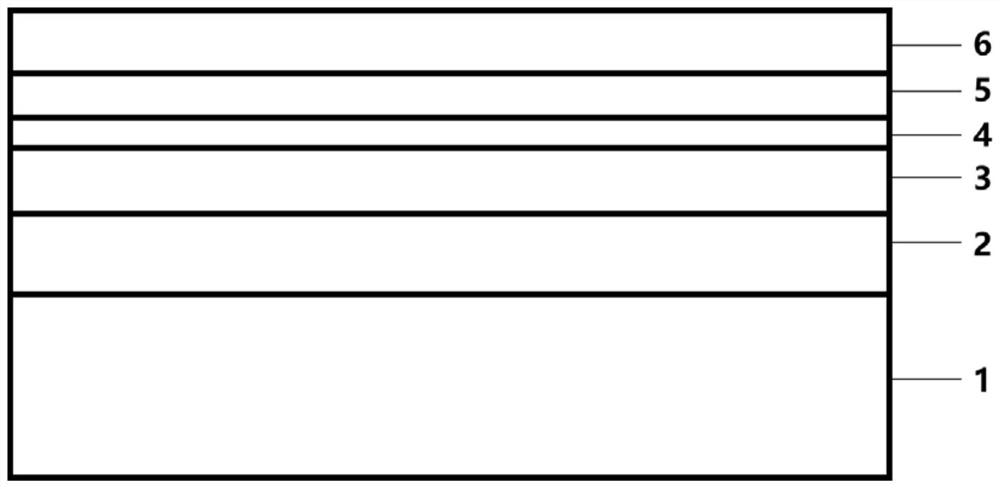

[0050] (2) make reflector electrode 6 in p-GaN layer 5 by electron beam evaporation method, wherein, deposition temperature is 120 ℃, reflector electrode is Ni / Ag / Pt / Au, and the thickness of reflector electrode 6 is 0.5 / 200 / 50 / 200nm. The structure obtained after this step is as follows figure 2 shown. ...

Embodiment 3

[0060] The preparation method of the vertical microcavity GaN-based Micro-LED provided in this embodiment includes the following steps:

[0061] (1) First, grow u-GaN layer 2 (5 μm in thickness), n-GaN layer 3 (5 μm in thickness), [InGaN (2 nm) / GaN ( 10nm)] 8 MQW (quantum well) layer 4 (thickness: 96nm), p-GaN layer 5 (thickness: 100nm), to obtain LED epitaxial material. The structure of the obtained LED epitaxial material in step (1) is as follows figure 1 shown.

[0062] (2) The mirror electrode 6 is fabricated on the p-GaN layer 5 by electron beam evaporation, wherein the deposition temperature is 120 degrees, and the mirror electrode is Ni / Ag / Pt / Au. The thickness of the mirror electrode 6 is 0.5 / 200 / 50 / 200 nm. The structure obtained after this step is as follows figure 2 shown.

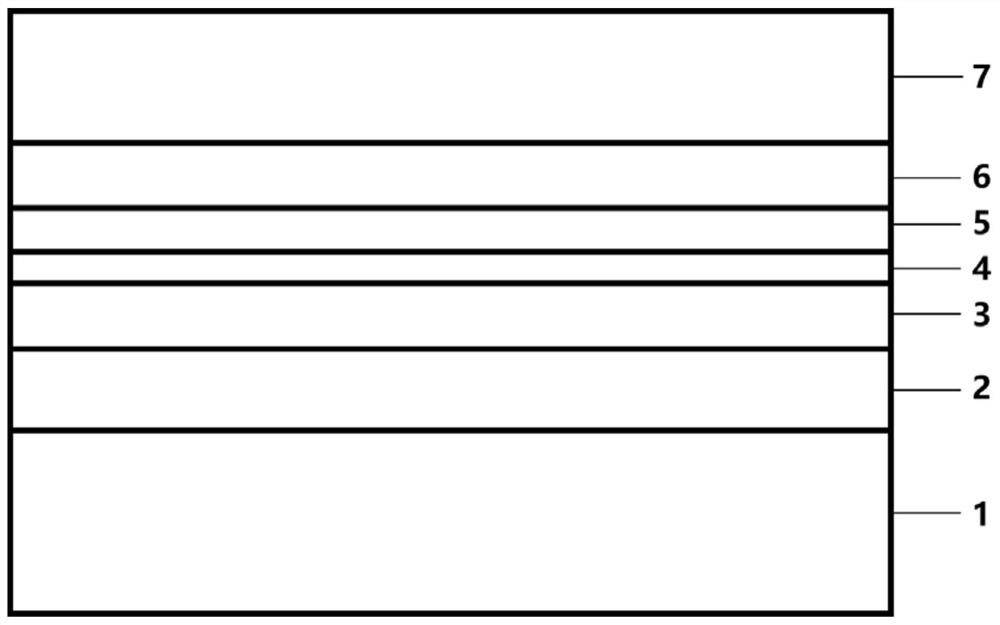

[0063] (3) Prepare a substrate 7 on the reflector electrode 6 obtained in step (2) by electroplating. Specifically, a layer of Cu is electroplated with a copper-plating electroplating solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com