Method for preparing solid polymer electrolyte by doping magnetic field orientation organic modified magnetic nanofibers

A solid polymer, magnetic nanotechnology, applied in the manufacture of electrolytes, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of PEO solid electrolyte film formation, thermal stability and mechanical strength reduction, restricting PEO solid electrolytes, etc. To achieve the effect of suppressing dendrites, good compatibility and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

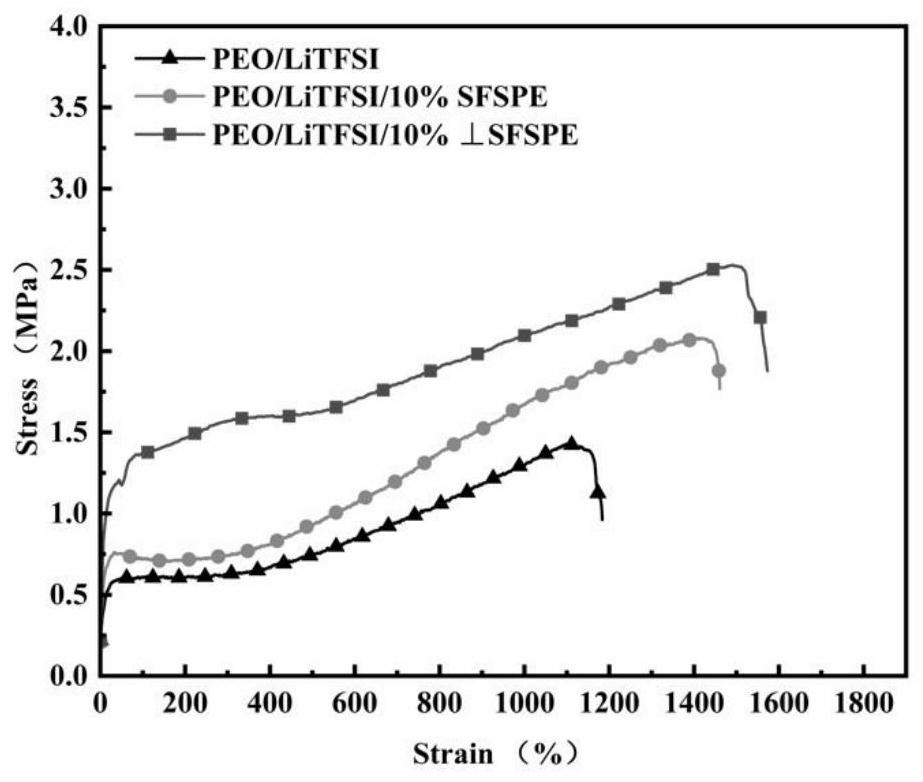

Embodiment 1

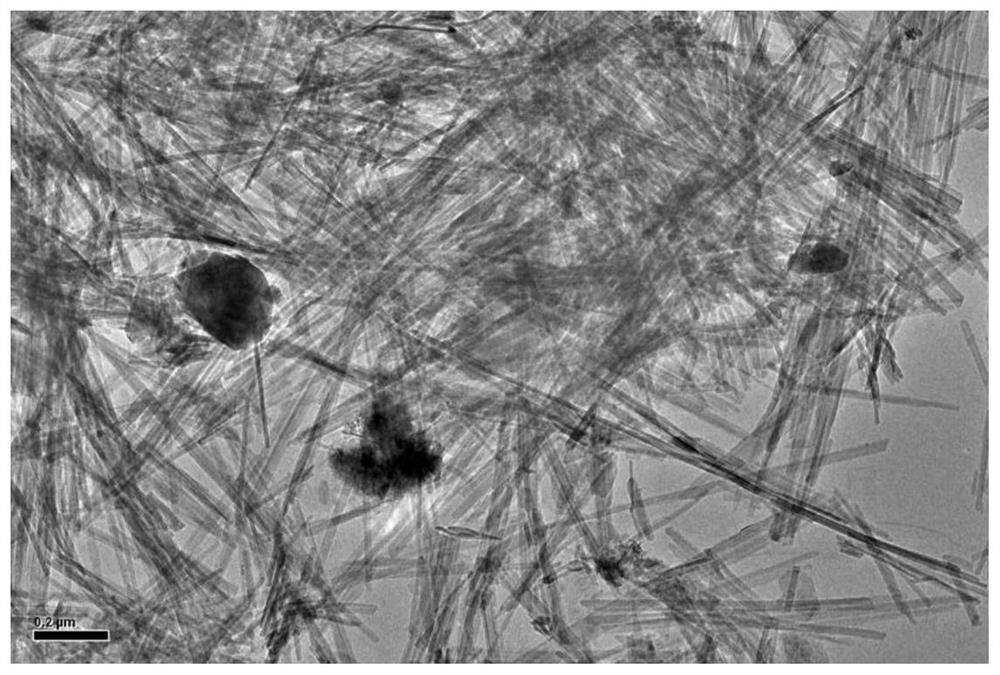

[0033] 1. Preparation of magnetic sepiolite: first, 4.0g FeCl 3 ·6H 2 O, 4.0g FeSO 4 ·7H 2 O was dissolved in 150mL deionized water, and stirred in a 250mL flask at 25°C for 20min; then, under vigorous stirring at 40°C, 6.0g of sepiolite was added to the flask, and after 20min, ammonia water was added to the stirring solution to pH ~ 9.0, and stirred in a water bath at 60 °C for 4 hours, when the precipitate was cooled to room temperature, washed three times with deionized water and ethanol.

[0034] 2. Use KH550 to organically modify the surface of magnetic sepiolite: first, under magnetic stirring at 40°C, disperse 6.0g magnetic sepiolite in 100g deionized water, then add 2.0g KH550 into the mixture solution, A homogeneous slurry is obtained. Then the pH of the solution was adjusted to about 5.0, stirred and heated at 80 °C for 4 hours; after the solution was cooled, the precipitate was washed with deionized water and ethanol several times.

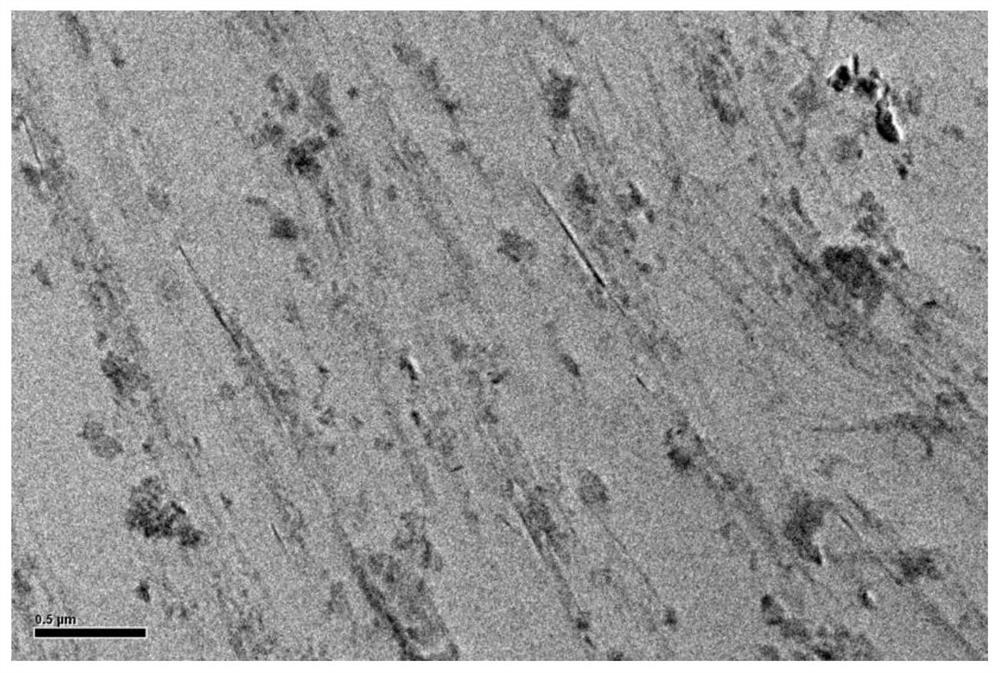

[0035] 3. Preparation of ma...

Embodiment 2

[0040] 1. Preparation of magnetic sepiolite: first, 2.0g FeCl 3 ·6H 2 O, 2.0g FeSO 4 ·7H 2 O was dissolved in 150mL deionized water, and stirred in a 250mL flask at 25°C for 20min; then, under vigorous stirring at 40°C, 6.0g of sepiolite was added to the flask, and after 20min, ammonia water was added to the stirring solution to pH ~ 9.0, and stirred in a water bath at 60 °C for 4 hours, when the precipitate was cooled to room temperature, washed three times with deionized water and ethanol.

[0041] 2. Use KH550 to modify the surface of magnetic sepiolite: first, under magnetic stirring at 40°C, disperse 6.0g of magnetic sepiolite in 100g of deionized water, then add 2.0g of KH550 into the mixture solution to obtain Uniform slurry. Then the pH of the solution was adjusted to about 5.0, stirred and heated at 80 °C for 4 hours; after the solution was cooled, the precipitate was washed with deionized water and ethanol several times.

[0042] 3. Preparation of magnetically o...

Embodiment 3

[0045] 1. Preparation of magnetic sepiolite: first, 2.0g FeCl 3 ·6H 2 O, 2.0g FeSO 4 ·7H 2 O was dissolved in 150mL deionized water, and stirred in a 250mL flask at 25°C for 20min; then, under vigorous stirring at 40°C, 6.0g of sepiolite was added to the flask, and after 20min, ammonia water was added to the stirring solution to pH ~ 9.0, and stirred in a water bath at 60 °C for 4 hours, when the precipitate was cooled to room temperature, washed three times with deionized water and ethanol.

[0046] 2. Use KH550 to modify the surface of magnetic sepiolite: first, under magnetic stirring at 40°C, disperse 6.0 g of magnetic sepiolite in 100 g of deionized water, then add 1.0 g of KH550 into the mixture solution to obtain Uniform slurry. Then the pH of the solution was adjusted to about 5.0, stirred and heated at 80 °C for 4 hours; after the solution was cooled, the precipitate was washed with deionized water and ethanol several times.

[0047] 3. Preparation of magneticall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com