Preparation method of a high-volume-fraction ceramic reinforced aluminum-based composite material

A high volume fraction, reinforced aluminum-based technology, applied in the field of aluminum-based composite materials, can solve the problems of difficult to achieve low thermal expansion coefficient, difficult to disperse ceramic reinforcements uniformly, poor mechanical properties, etc., to achieve fine grain size, low thermal expansion coefficient, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

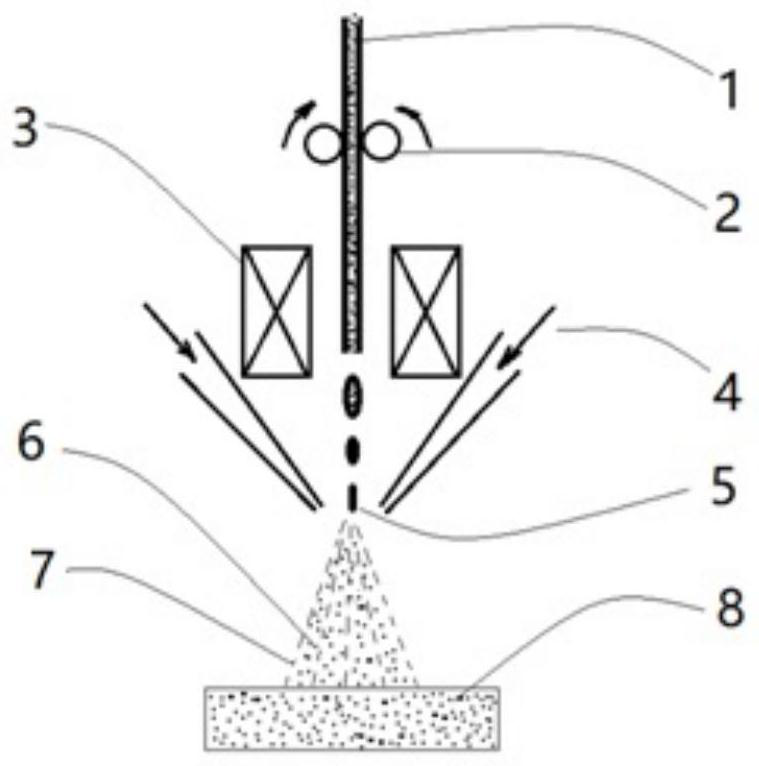

[0032] Such as figure 1 As shown, this embodiment provides a device for producing high volume fraction ceramic reinforced aluminum matrix composites, the working process of which is as follows: the aluminum wire 1 wrapped with ceramic particles is transported to the induction heater 3 through the conveying device 2, Perform rapid induction heating and melting to form molten droplets 5 wrapped with ceramic particles, and then high-pressure nitrogen gas 4 atomizes the molten droplets 5 from the surroundings of the molten droplets 5 to form micro-nano aluminum alloy droplets 7 and The ceramic particles 6 are co-deposited to form a high volume fraction ceramic reinforced aluminum matrix composite material 8 .

[0033] The aluminum alloy used in this application is 2024 aluminum alloy, and the mass percentages are as follows: 4% Cu, 1.8% Mg, 0.4% Mn, and the balance Al.

Embodiment 2

[0035] This example provides a method for preparing a high volume fraction ceramic reinforced aluminum matrix composite material, which is completed based on the device in Example 1. The specific preparation method includes the following steps:

[0036] S1. Pretreatment: Wrap SiC particles into aluminum alloy thin strips, and then weld the sealing part of the aluminum alloy thin strips to prepare aluminum wires filled with SiC particles, wherein the volume fraction of SiC particles is 45%;

[0037] S2. Heating and melting: transport the aluminum wire prepared in step S1 to an induction heater, rapidly induce heating and melting to form molten droplets filled with SiC particles, and the induction heating temperature is 1000°C;

[0038] S3. Atomization deposition: Use high-pressure nitrogen to atomize the molten droplets in step S2 into micro-nano-scale aluminum alloy droplets and SiC particles. The nitrogen pressure is 3MPa, the temperature is -15°C, and the deposition distance ...

Embodiment 3

[0040] This example provides a method for preparing a high volume fraction ceramic reinforced aluminum matrix composite material, which is completed based on the device in Example 1. The specific preparation method includes the following steps:

[0041] S1. Pretreatment: Wrap SiC particles into aluminum alloy thin strips, and then weld the sealing part of the aluminum alloy thin strips to prepare aluminum wires filled with SiC particles, wherein the volume fraction of SiC particles is 65%;

[0042] S2. Heating and melting: transport the aluminum wire prepared in step S1 to an induction heater, rapidly induce heating and melting to form molten droplets filled with SiC particles, and the induction heating temperature is 850°C;

[0043] S3. Atomization deposition: Use high-pressure nitrogen to atomize the molten droplets in step S2 into micro-nano-scale aluminum alloy droplets and SiC particles. The nitrogen pressure is 5MPa, the temperature is -20°C, and the deposition distance i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com