High-temperature flue gas desulfurization, dust removal and waste heat recovery self-balancing system

A technology for desulfurization, dust removal, and waste heat recovery. It is used in the reduction of greenhouse gases, gas treatment, and indirect heat exchangers. It can solve the problems of desulfurization water balance control and the difficulty of co-processing with waste heat utilization, and achieve co-processing of waste heat recovery and desulfurization and dust removal. effect of efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

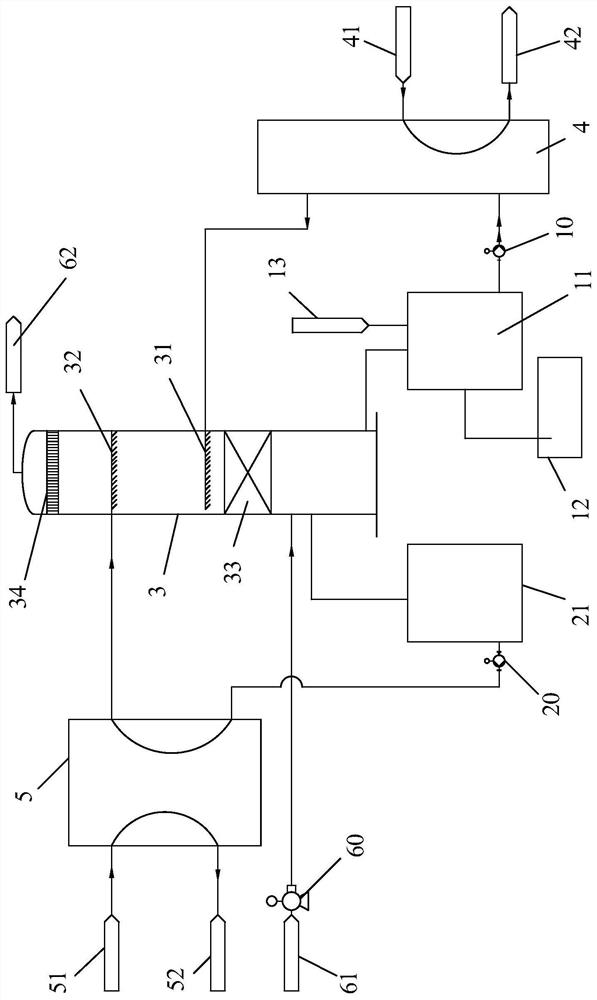

[0025] Such as figure 1 As shown, this embodiment discloses a high-temperature flue gas desulfurization and dust removal and waste heat recovery self-balancing system. The high-temperature flue gas desulfurization and dust removal and waste heat recovery self-balancing system includes an absorption tower 3, and the absorption tower 3 has a flue gas inlet 61 and a flue gas outlet 62. It also has a first solution outlet and a second solution outlet.

[0026] The high-temperature flue gas desulfurization, dust removal and waste heat recovery self-balancing system also includes a primary spray 31, a first heat exchanger 4, and a first circulation loop, wherein the first circulation loop is connected from the outlet of the first solution and connected to the primary spray Shower 31, the solution in the first circulation loop excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com