Wetting-resistant and oil-stain-resistant Janus type distillation membrane as well as preparation method and application thereof

A distillation membrane, anti-oil technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of being easily wetted by oil-containing liquids and low surface tension substances, and achieve not easy to fall off, good stability, and simple preparation. Fast, effective and environmentally friendly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

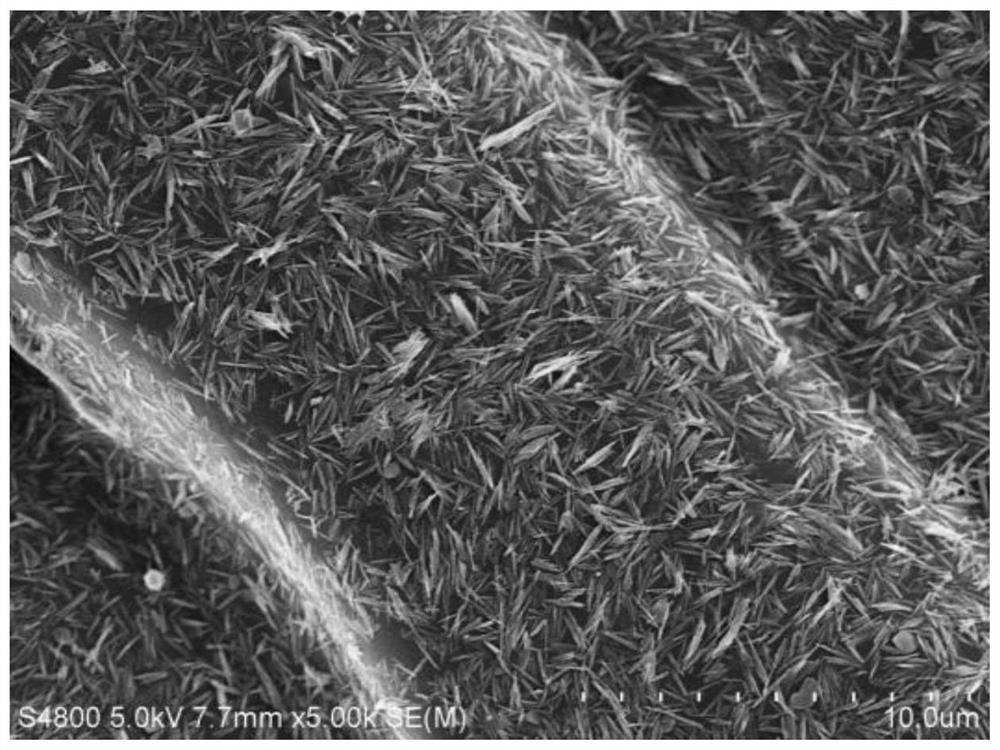

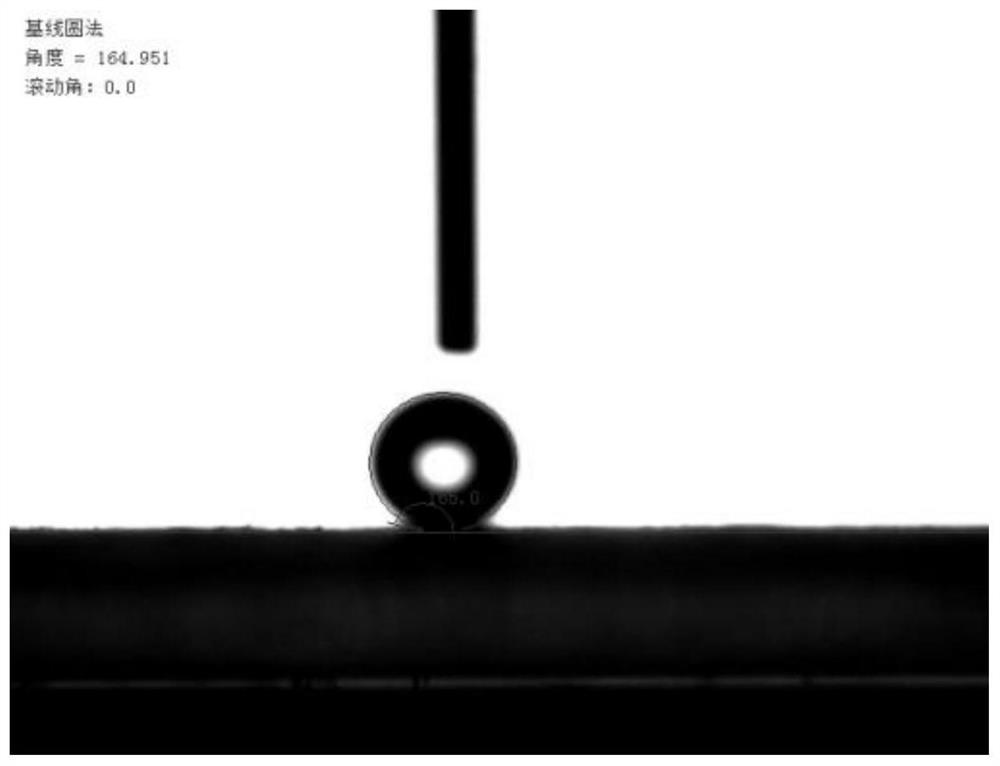

[0052] A kind of preparation method of the Janus type distillation membrane of resistance to wetting, oil pollution, the steps are as follows:

[0053] (1) Dopamine was added to 10 mM Tirs-HCl buffer solution with pH=8.5, so that the concentration of dopamine solution was 0.5 g / L. Put a commercial PTFE membrane with a size of 3*8cm into the PDA solution and vibrate at 100r / min and a temperature of 25°C to make the PDA evenly adhere to the surface of the membrane.

[0054] (2) Rinse the membrane surface with deionized water at least three times to obtain a hydrophilic cortical basement membrane;

[0055] (3) Add 5gPAL to 50mL, the concentration is C HCl =1M hydrochloric acid solution and stirred for 2h for activation, the stirring speed was 650rpm. Then it was washed with deionized water to pH 6, then dried in a vacuum oven at 105 °C to constant weight, and the dried PAL was ground into a powder.

[0056] (4) Take 0.1 g of PAL activated in step (3) and add it to 60 mL of Tir...

Embodiment 2

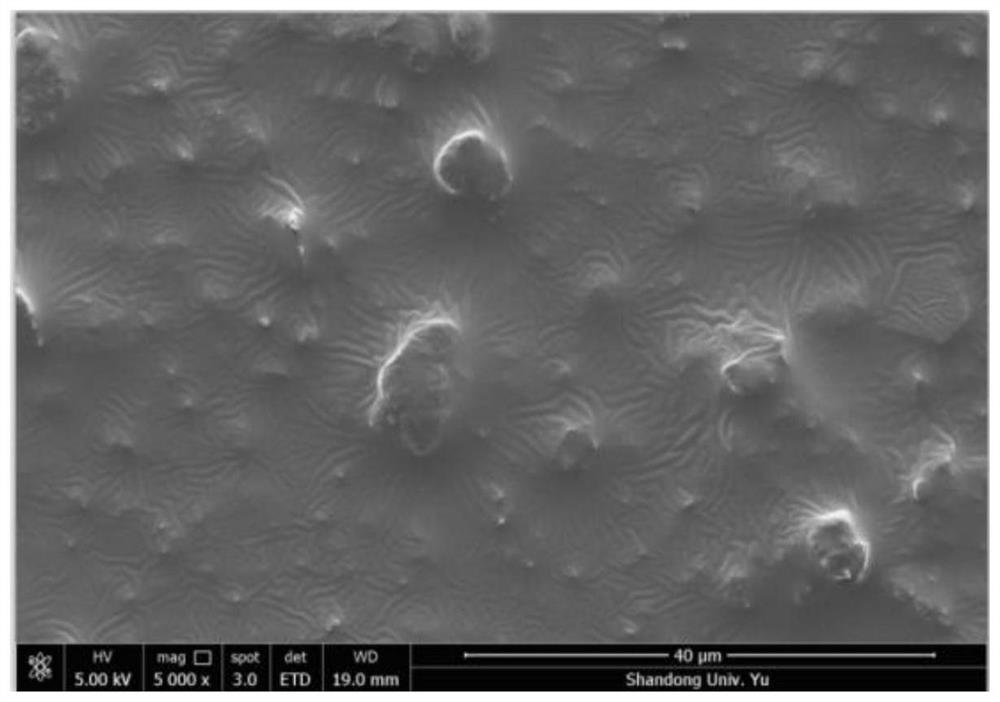

[0061] A kind of preparation method of the Janus type distillation membrane of resistance to wetting, oil pollution, the steps are as follows:

[0062] (1) Dopamine was added to 10 mM Tirs-HCl buffer solution with pH=8.5, so that the concentration of dopamine solution was 0.5 g / L. Put a commercial PVDF membrane with a size of 3*8cm into the PDA solution and shake it at 100r / min and at a temperature of 25°C to make the PDA evenly adhere to the surface of the membrane;

[0063] (2) Rinse the membrane surface with deionized water at least three times to obtain a hydrophilic cortical basement membrane;

[0064] (3) Take 0.1g CNT and add it to 50mL Tirs-HCl buffer solution for ultrasonication, then add dopamine to the uniformly mixed suspension to make the concentration reach 0.05-1.5g / L, stir at room temperature for 3 hours, and wait until the solution is fully mixed , was centrifuged and washed to neutral, and dried in vacuum at 60°C for 10 hours to obtain dopamine-modified CNTs...

Embodiment 3

[0068] A kind of preparation method of the Janus type distillation membrane of resistance to wetting, oil pollution, the steps are as follows:

[0069] (1) Dopamine was added to 10 mM Tirs-HCl buffer solution with pH=8.5, so that the concentration of dopamine solution was 0.5 g / L. Put a commercial PP film with a size of 3*8cm into the PDA solution and shake it at 100r / min and at a temperature of 25°C to make the PDA evenly adhere to the surface of the film.

[0070] (2) Rinse the membrane surface with deionized water at least three times to obtain a hydrophilic cortical basement membrane;

[0071] (3) Take 0.1g CNF and add it into 50mL Tirs-HCl buffer solution for ultrasonication, then add dopamine to the uniformly mixed suspension to make the concentration reach 0.05-1.5g / L, and stir at room temperature for 3 hours. After the solution is fully mixed, it is centrifuged and washed to neutrality. And vacuum-dried at 60°C for 10 hours to obtain dopamine-modified CNF.

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com