Technology for producing wood-like aluminium alloy section bar with environmental protection and super weatherability

A technology of aluminum alloy profile and production process, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems that do not meet the requirements of environmental protection aluminum profile standards, cannot be used outdoors, and have low economic value. Environmental protection, not easy to fade, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

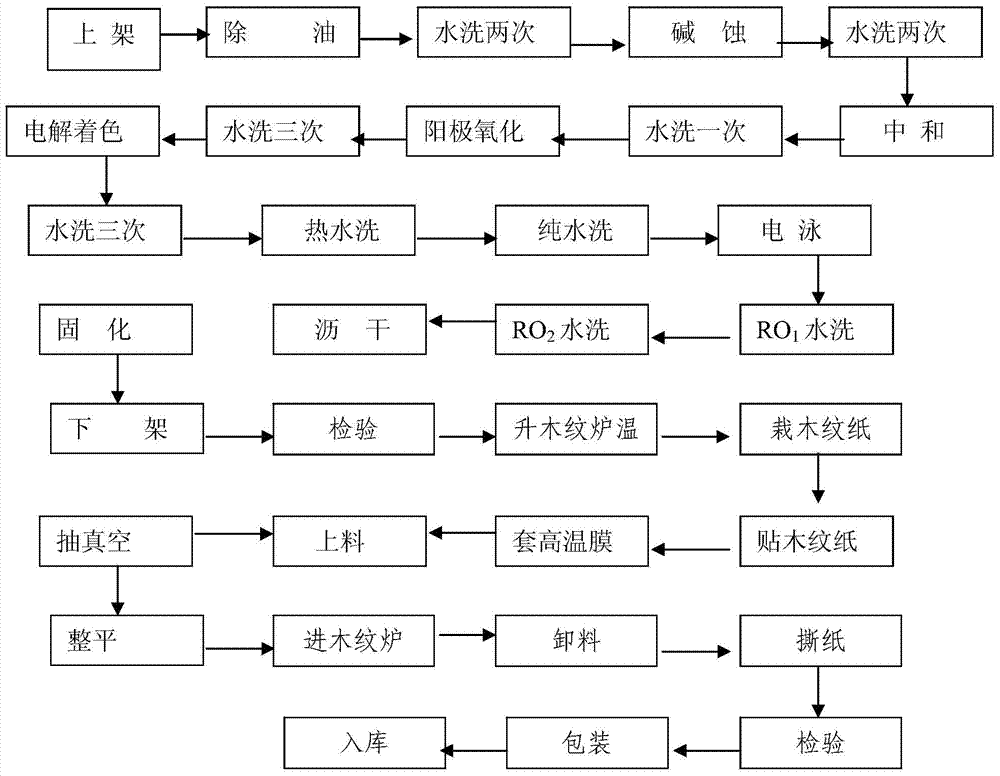

[0031] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0032] refer to figure 1 :

[0033] (1) Shelving process

[0034] 1. According to the different cross-sections of aluminum alloy profiles, they must not be put on the shelves in the same row. Try to put the same type of material in the same row for each shelf.

[0035] 2. Before putting on the shelves, the conductive edges and corners of the conductive rod must be evenly polished with a file. When moving the conductive rod, use a grinder to grind the contact surface of the conductive beam and the conductive rod. The conductive rod has been used for a long time, and the cross section is too small, so it needs to be replaced. Under normal circumstances, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com