Preparation method of rice straw modified charcoal for removing tetracycline in water body

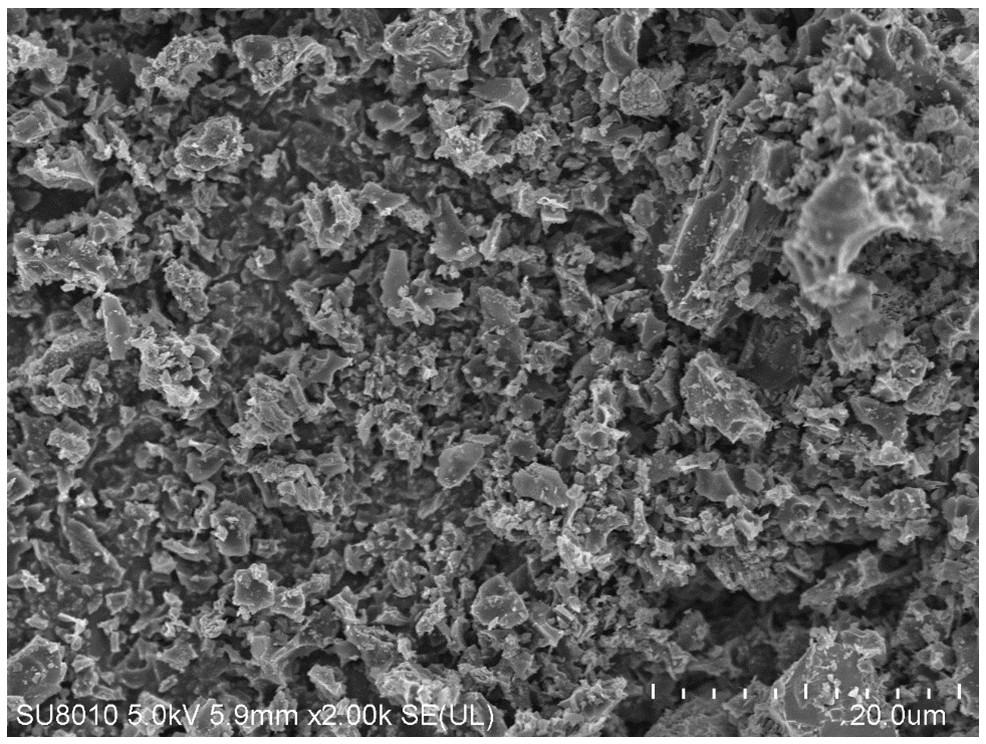

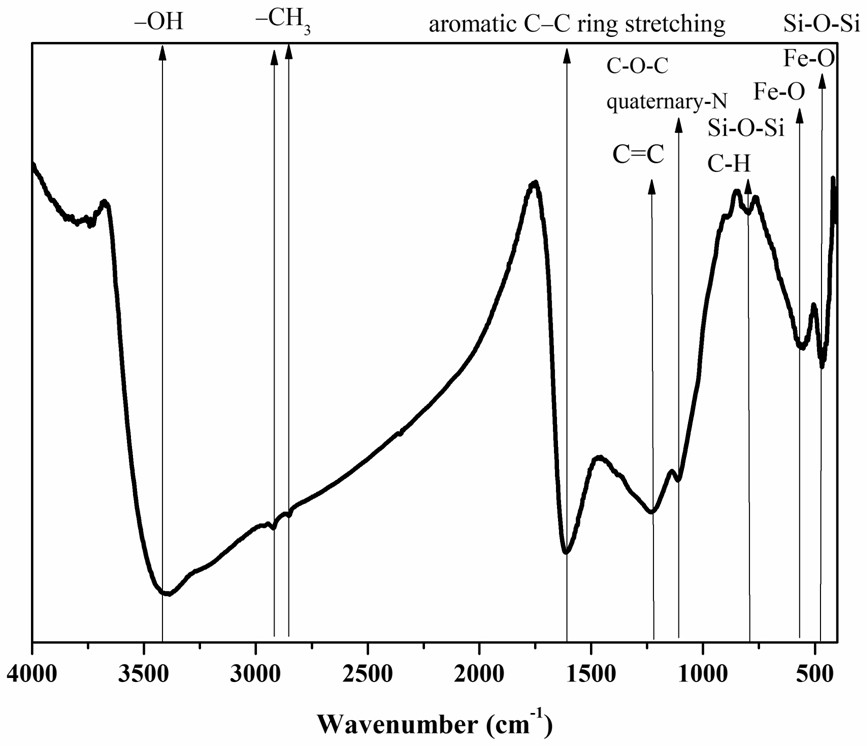

A technology of rice straw and biochar, which is applied in water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of small adsorption capacity and difficult recovery, and achieves changes in surface polarity, rich resources, and increased The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of preparation operation steps of rice straw modified biochar that removes tetracycline in water is as follows:

[0050] (1) Pretreatment

[0051] The rice stalks were washed with water to remove the ash on the surface, and then dried in a blast dryer at a temperature of 105°C. After drying, the rice stalks were cut into 3 cm long small stalks with scissors, and then the small stalks were crushed with a pulverizer and passed through a 30-mesh sieve to obtain rice straw powder.

[0052] (2) Dipping treatment

[0053] 3 grams of rice straw powder, 27 grams of ferric chloride and 6 grams of urea were thoroughly mixed in 100 mL of pure water, stirred magnetically for 4 hours, and then the mixed solids were dried in a blast drying oven at a drying temperature of 105 °C. Drying time was 24 h to give mixed solids.

[0054] (3) Carbonization treatment

[0055] Put the mixed solid into a quartz boat, transfer it to a tubular muffle furnace, and perform pyrolysis under...

Embodiment 2

[0061] A kind of preparation operation steps of rice straw modified biochar that removes tetracycline in water is as follows:

[0062] (1) Pretreatment

[0063] The rice stalks were washed with water to remove the ash on the surface, and then dried in a blast dryer at a temperature of 105°C. After drying, the rice straw was cut into 5 cm long small stalks with scissors, and then the small stalks were crushed with a pulverizer and passed through a 40-mesh sieve to obtain rice straw powder.

[0064] (2) Dipping treatment

[0065] 5 grams of rice straw powder, 27 grams of ferric chloride and 6 grams of urea were fully mixed in 150 mL of pure water, stirred magnetically for 3 hours, and then the mixed solids were dried in a blast drying oven at a drying temperature of 90 °C. Drying time was 24 h to give mixed solids.

[0066] (3) Carbonization treatment

[0067] Put the mixed solid into a quartz boat, transfer it to a tubular muffle furnace, and perform pyrolysis under a nitro...

Embodiment 3

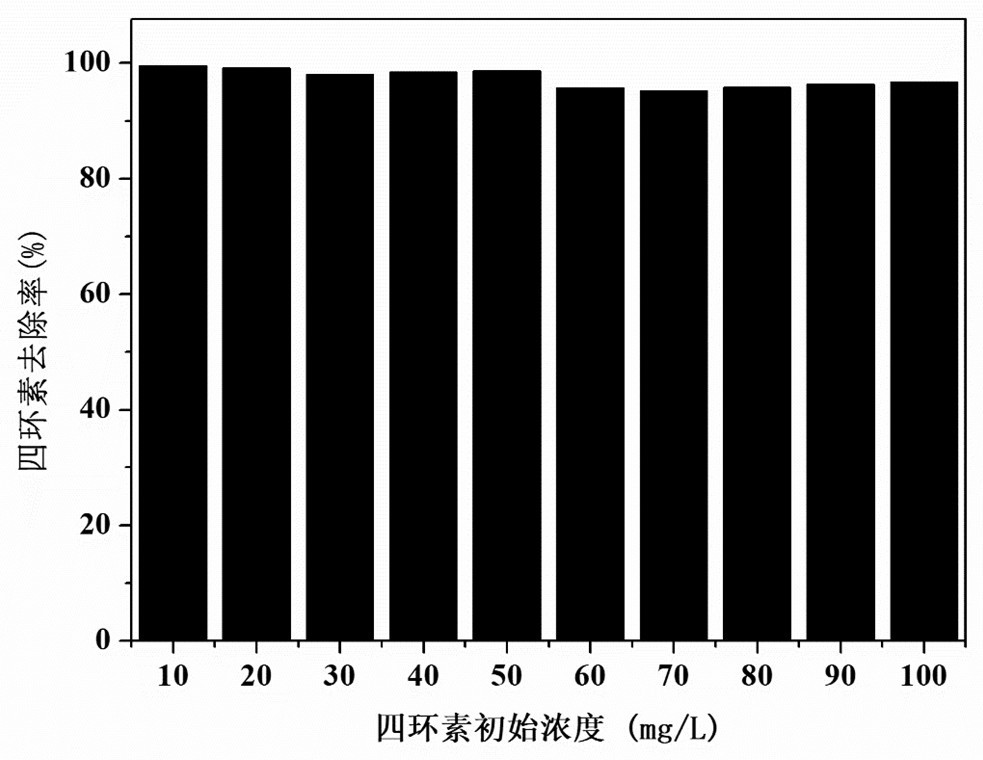

[0072] Application of Rice Straw Modified Biochar

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com