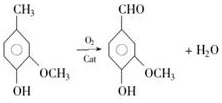

Production process and reaction equipment for synthesizing vanillin from 4-methyl guaiacol

A technology of methylguaiacol and production process, which is applied in the direction of bulk chemical production, condensation preparation of carbonyl compounds, organic compound/hydride/coordination complex catalyst, etc. Low yield and other problems, to achieve high yield, good selectivity, continuous separation and circulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

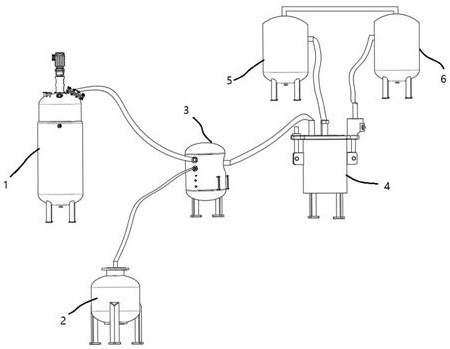

[0043] 4-methylguaiacol synthetic vanillin production technology, comprises the following steps:

[0044] S1. Prepare the raw material solution of 4-methylguaiacol and nitrosodimethylaniline in the mixing reactor 1, and supplement the catalyst in the mixing reactor 1;

[0045] The catalyst uses cobalt and iron as active components and honeycomb-shaped thermoplastic polyurethane elastic particles as carriers;

[0046] S2. Move the mixture in step S1 to the reactor 2, and at the same time, input high-pressure oxygen into the reactor 2 through the high-pressure oxygen pipe 3, and carry out catalytic oxidation reaction with the mixture in step S1 at 0.3 MPa and 80° C. for 1 hour;

[0047] S3, the product of step S2 is transported to the supercritical fluid extraction equipment 4 to extract the product, the extracted liquid phase is the obtained vanillin, the extracted filtrate is filtered, and the gas is separated through the separation tank 5 at the same time The liquid is separ...

Embodiment 2

[0056] 4-methylguaiacol synthetic vanillin production technology, comprises the following steps:

[0057] S1. Prepare the raw material solution of 4-methylguaiacol and nitrosodimethylaniline in the mixing reactor 1, and supplement the catalyst in the mixing reactor 1;

[0058] The catalyst uses cobalt and iron as active components and honeycomb-shaped thermoplastic polyurethane elastic particles as carriers;

[0059] S2. Move the mixture in step S1 to the reactor 2, and at the same time, input high-pressure oxygen into the reactor 2 through the high-pressure oxygen pipe 3, and carry out catalytic oxidation reaction with the mixture in step S1 at 0.4 MPa and 90° C. for 2 hours;

[0060] S3, the product of step S2 is transported to the supercritical fluid extraction equipment 4 to extract the product, the extracted liquid phase is the obtained vanillin, the extracted filtrate is filtered, and the gas is separated through the separation tank 5 at the same time The liquid is sepa...

Embodiment 3

[0069] 4-methylguaiacol synthetic vanillin production technology, comprises the following steps:

[0070] S1. Prepare the raw material solution of 4-methylguaiacol and nitrosodimethylaniline in the mixing reactor 1, and supplement the catalyst in the mixing reactor 1;

[0071] The catalyst uses cobalt and iron as active components and honeycomb-shaped thermoplastic polyurethane elastic particles as carriers;

[0072] S2. Move the mixture in step S1 to reactor 2, and at the same time, input high-pressure oxygen into reactor 2 through high-pressure oxygen pipe 3, and carry out catalytic oxidation reaction with the mixture in step S1 at 0.5 MPa and 100° C. for 3 hours;

[0073] S3, the product of step S2 is transported to the supercritical fluid extraction equipment 4 to extract the product, the extracted liquid phase is the obtained vanillin, the extracted filtrate is filtered, and the gas is separated through the separation tank 5 at the same time The liquid is separated, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com