Preparation method of polycarboxylate superplasticizer with high viscosity reduction performance

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete water reducing agent, can solve the problems of not conforming to the concept of green environmental protection, long synthesis route, expensive raw materials, etc., and achieve stable molecular structure and performance of the product, uniform molecular weight distribution, The effect of high reaction polymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

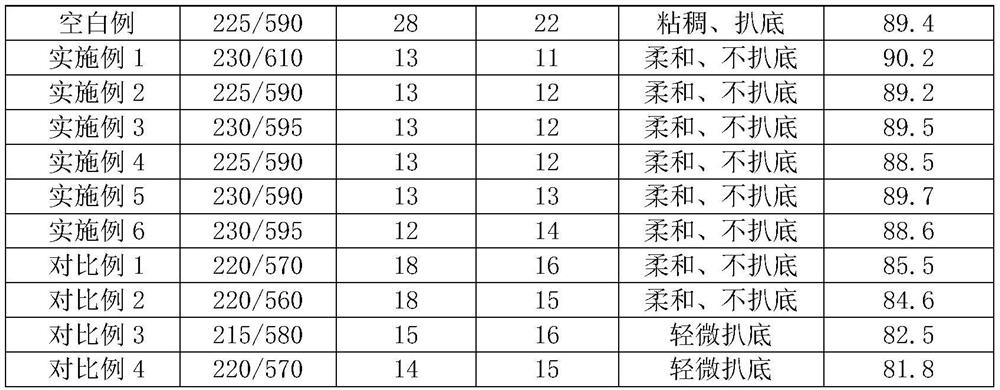

Examples

Embodiment 1

[0028] The preparation method of the polycarboxylate water reducer provided in this embodiment is:

[0029] S1. Take 10g of trifluoroethanol and 12g of acryloyl chloride and mix evenly, that is, the molar ratio of the two is 1:1.33. Heat up to 45°C and add a catalyst for constant temperature reflux reaction for 5 hours. After the reaction is completed, cool to room temperature and extract 4 times with an organic solvent. Obtain the viscosity-reducing functional monomer I after removing the organic solvent;

[0030] S2. Take 10g of maleic anhydride and raise the temperature to 120-150°C, add 35g of linear diol compound (that is, the molar ratio of the two is 1:3.3) for constant temperature reaction for 4h, after the reaction is completed, cool to room temperature, add water to the solid The content is 60% and stirred evenly to obtain the viscosity-reducing functional monomer II;

[0031] S3. Take 100g of polyether monomers and 10g of maleic anhydride and add them into 40g of w...

Embodiment 2

[0034] The preparation method of the polycarboxylate superplasticizer in this example is basically the same as in Example 1, except that in step S3, the amount of the viscosity-reducing functional monomer I is 30 g, and the amount of the viscosity-reducing functional monomer II is 20 g. , that is, the molar ratio of the polyether monomer, the viscosity-reducing functional monomer I, and the viscosity-reducing functional monomer II is 10:3:2.

Embodiment 3

[0036] The preparation method of the polycarboxylate superplasticizer in this example is basically the same as that in Example 1, except that in step S3, the amount of the viscosity-reducing functional monomer I is 10 g, and the amount of the viscosity-reducing functional monomer II is 40 g. , that is, the molar ratio of the polyether monomer, the viscosity-reducing functional monomer I, and the viscosity-reducing functional monomer II is 10:1:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com