A kind of hydrophilic polyurethane foam dressing and preparation method thereof

A hydrophilic polyurethane and foam technology, applied in bandages, absorbent pads, medical science and other directions, can solve the problems of unsustainable hydrophilicity of polyurethane foam dressings, reduced mechanical properties, weak binding effect, etc., to achieve abundant reserves and reduce production. Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of hydrophilic polyurethane foam dressing, comprises the steps:

[0028] S1. Mix vegetable oil-based polyol and polyethylene glycol uniformly according to a preset mass ratio to obtain a polyol mixture; then add a predetermined amount of foaming agent, catalyst, surfactant and filler to the polyol mixture, After heating, stirring and fully mixing, the mixed solution I was obtained;

[0029] S2. The mixed solution I obtained in step S1 is left to stand, and after the air bubbles are removed, polyisocyanate is added according to the preset isocyanate index, and the mixed solution II is obtained after stirring rapidly to make it evenly mixed; II is poured into the mold, and after fully reacting, aging treatment is carried out to obtain a hydrophilic polyurethane foam dressing.

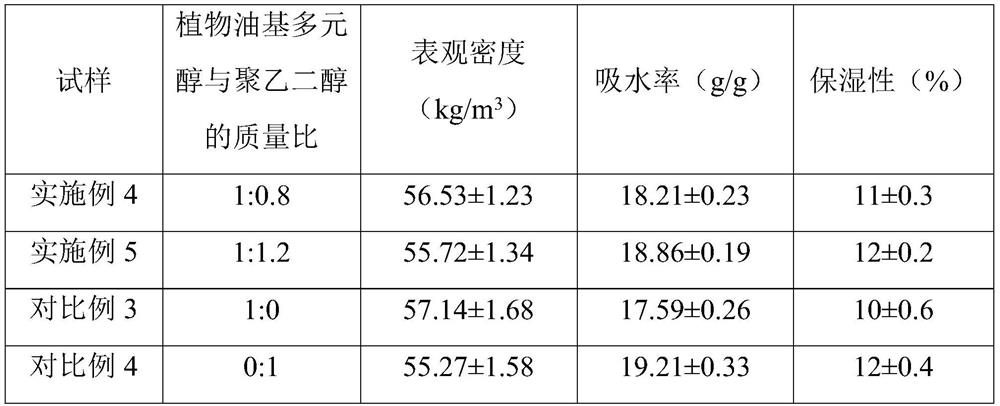

[0030] In step S1, the preset mass ratio of the vegetable oil-based polyol to polyethylene glycol is 1:(0.8-1.2).

[0031] In step S1, the fill...

Embodiment 1

[0041] Embodiment 1 provides a kind of preparation method of hydrophilic polyurethane foam dressing, comprises the steps:

[0042] S1. Weigh 35g of soybean oil-based polyol and polyethylene glycol according to the mass ratio of 1:1, place them in a clean plastic cup, and mix them uniformly to obtain a polyol mixture; then weigh 1.68g of distilled water (foaming agent ), 0.7g triethylenediamine (catalyst), 0.7g silicone oil (surfactant) and 0.07g sodium hyaluronate (filler), mix them uniformly and add them to the polyol mixture, at 65°C Stir for 5 min to make it evenly mixed to obtain the mixed solution I.

[0043] S2. The mixed solution I obtained in step S1 was left to stand for 2 minutes to remove air bubbles, and then calculated according to the isocyanate index of 1.2 and weighed 37.95g polyisocyanate, which was composed of 80% 2,6-toluene diisocyanate and 20 % of 4,4'-diphenylmethane diisocyanate; after adding the polyisocyanate into the mixed solution I, stir rapidly at...

Embodiment 2~3 and comparative example 2

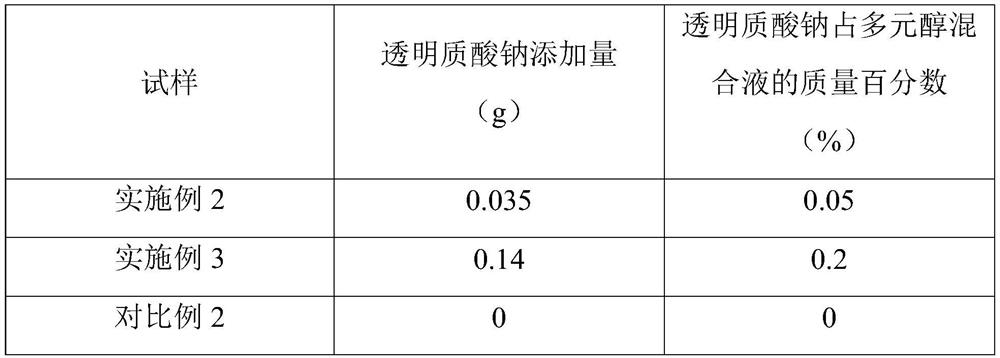

[0051] Embodiments 2 to 3 and Comparative Example 2 respectively provide a method for preparing a hydrophilic polyurethane foam dressing. Compared with Example 1, the difference is that the amount of sodium hyaluronate used as a filler in step S1 is changed , the specific sodium hyaluronate addition amount corresponding to each embodiment and comparative example and its mass percentage in the polyol mixture are shown in Table 1; the rest of the steps are the same as in Example 1, and will not be repeated here.

[0052] Table 1 The amount of sodium hyaluronate added and its proportion in Examples 2 to 3 and Comparative Example 2

[0053]

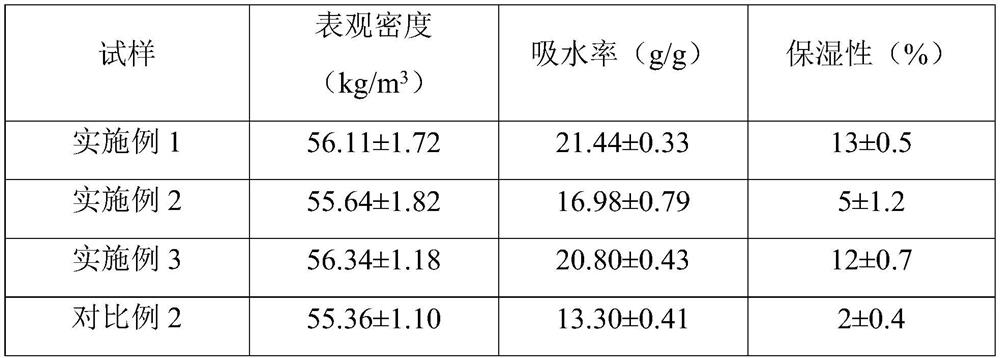

[0054] In order to further evaluate the performance of the hydrophilic polyurethane foam dressings prepared in the above examples and comparative examples, the apparent density, water absorption rate and moisture retention were tested respectively, and the results are shown in Table 2.

[0055] The performance parameter of table 2 embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com