A kind of antiscaling polypropylene material and preparation method thereof

A technology of polypropylene material and polypropylene resin, which is applied in the field of antiscaling polypropylene materials for pipelines and its preparation, and polypropylene modified materials, which can solve problems such as pipeline blockage, equipment corrosion, and metal transportation pipeline corrosion, and achieve reduction Effect of contact, reduction of mold release stress, and reduction of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of NiFe 2 o 4 : NiO and Fe 2 o 3 According to the molar ratio of 1:1, it is mixed by ball mill, dried, and subjected to solid phase synthesis at 1100°C for 8 hours in an air atmosphere, and then crushed by a ball mill to obtain a powder with a particle size of 10-30 μm.

[0030] Preparation of anti-scaling polypropylene material:

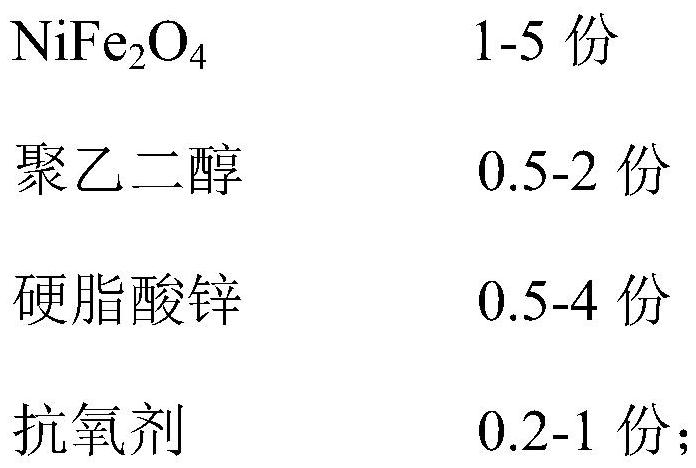

[0031] 93.5 parts of polypropylene, 3 parts of NiFe 2 o 4 , 1 part of polyethylene glycol, 2 parts of zinc stearate, 0.5 part of antioxidant, melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, extruded and granulated at 230 ° C to obtain scale inhibition Polypropylene material.

Embodiment 2

[0033] Preparation of NiFe 2 o 4 :

[0034] NiO and Fe 2 o 3 According to the molar ratio of 1:1, it is mixed by ball mill, dried, and subjected to solid phase synthesis at 1050°C for 10 hours in an air atmosphere, and then crushed by a ball mill to obtain a powder with a particle size of 10-30 μm.

[0035] Preparation of anti-scaling polypropylene material:

[0036] 92.7 parts of polypropylene, 2 parts of NiFe 2 o 4 , 1.5 parts of polyethylene glycol, 3 parts of zinc stearate, and 0.8 parts of antioxidant are melt-mixed and dispersed in a twin-screw extruder with an aspect ratio of 36:1, extruded and granulated at 210°C to obtain scale inhibition Polypropylene material.

Embodiment 3

[0038] Preparation of NiFe 2 o 4 :

[0039] NiO and Fe 2 o 3 According to the molar ratio of 1:1, it is mixed by ball mill, dried, and subjected to solid phase synthesis at 1150°C for 7 hours in an air atmosphere, and then crushed by a ball mill to obtain a powder with a particle size of 10-30 μm.

[0040] Preparation of anti-scaling polypropylene material:

[0041] 93.9 parts of polypropylene, 4 parts of NiFe 2 o 4 , 0.8 parts of polyethylene glycol, 1 part of zinc stearate, and 0.3 parts of antioxidant are melt-mixed and dispersed in a twin-screw extruder with an aspect ratio of 34:1, extruded and granulated at 190°C to obtain scale inhibition Polypropylene material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com