Negative plate as well as preparation method and application thereof

A technology of negative electrode sheet and negative electrode, applied in the field of negative electrode sheet and its preparation, can solve the problems of unstable binder network, uneven distribution of conductive carbon, influence on safety, etc., achieve excellent cycle performance and rate performance, and simple preparation method Ease of operation and the effect of improving the overall electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

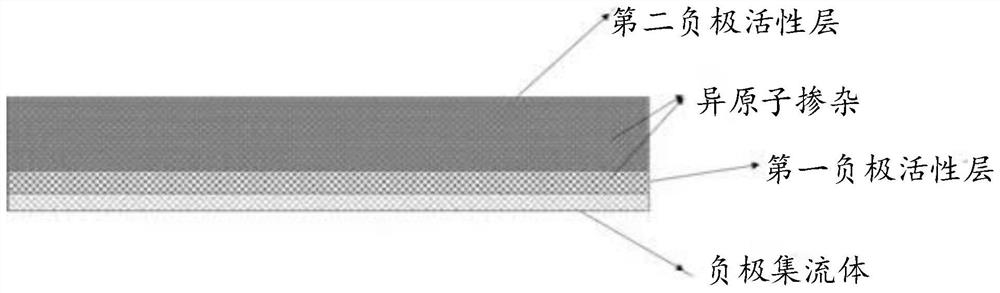

[0094] According to another aspect of the present invention, the present invention relates to the preparation method of the negative electrode piece, comprising the following steps:

[0095] The surface of the negative collector matrix is coated with at least one side of the carbon material slurry, after drying to obtain a negative collector with a carbon material layer; the first negative electrode slurry is coated on the surface of the carbon material layer away from the negative collector matrix, and the first negative active layer is given after drying; the first negative active layer is coated with a second negative electrode slurry on the surface away from the negative collector fluid matrix, and the second negative electrode active layer is obtained after drying;

[0096] The first negative electrode slurry comprises the first negative electrode active material, a first binder, a first conductive agent and a first solvent;

[0097] The second negative electrode slurry compri...

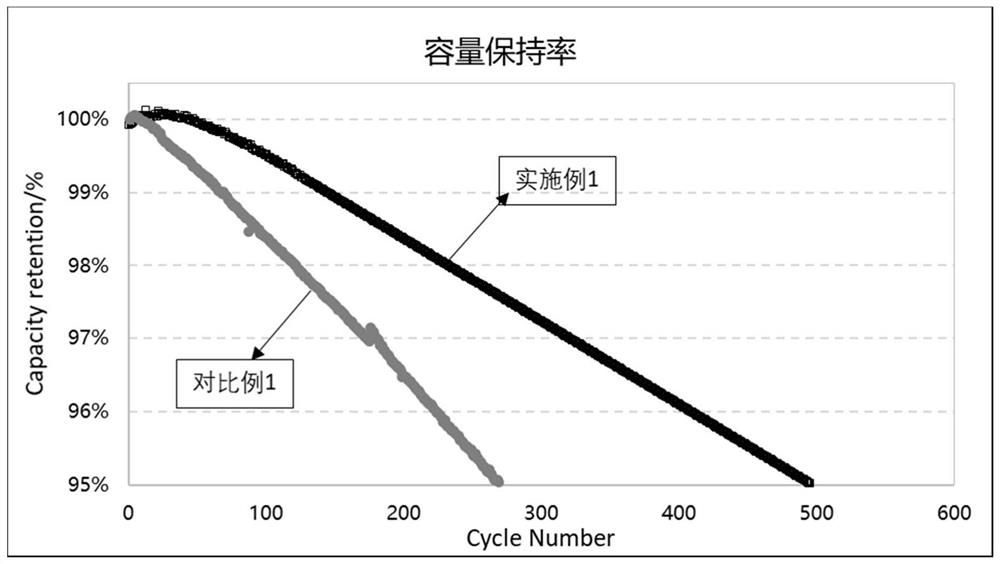

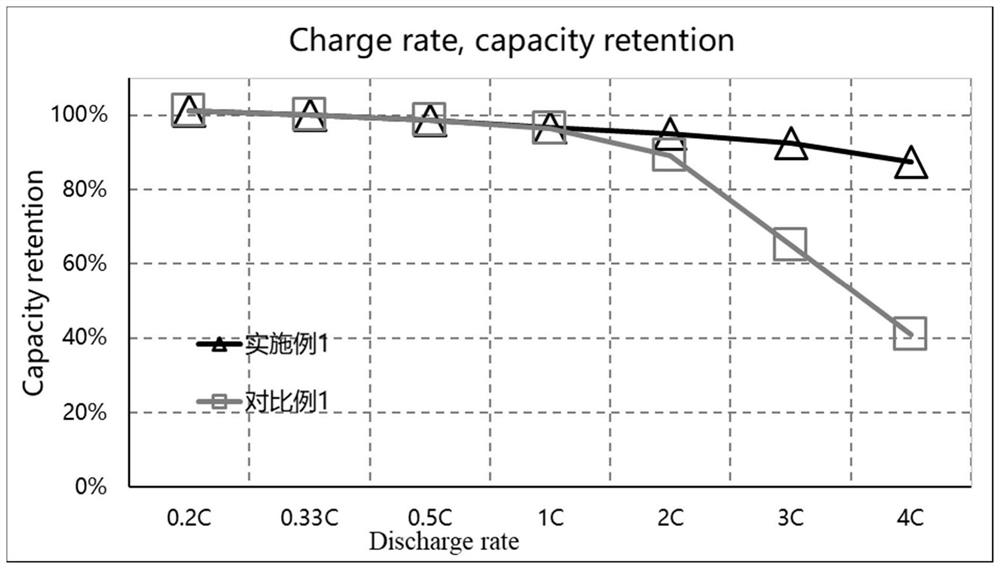

Embodiment 1

[0120] A method for preparing negative electrode sheets, comprising the following steps:

[0121] 1. Preparation of the first negative electrode active material and the second negative electrode active material

[0122] SiO was treated first under protective gas conditions to obtain a silicon-oxygen composite substrate, and then deposited the carbon source on the surface of the silicon-oxygen composite substrate by vapor deposition to form a carbon-coated silicon-oxygen material; the carbon-coated silicon-oxygen material and the nitrogen-containing substance were uniformly dispersed by aqueous solvent method, and then dried in N by blowing 2 The second heat treatment is carried out under atmosphere to form a modified silicon-based anode active material doped with N atoms; wherein the carbon source is acetylene; the temperature of the first heat treatment is 400 °C, and the insulation time is 60min; the temperature of vapor deposition is 800 °C, the time is 30min; the nitrogen-conta...

Embodiment 2

[0130] A method for preparing a negative electrode sheet, in addition to the preparation of the first negative electrode active material, the carbon-coated silicon oxygen material and the nitrogen-containing substance mass ratio is 1:2, other conditions are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com