Peach blossom cellulose fiber and preparation process thereof

A technology of cellulose fiber and peach blossom, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc. Fastness, poor utilization of active substances and other problems, to achieve the effect of maintaining spiritual pleasure, improving uniformity of bonding, and protecting the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

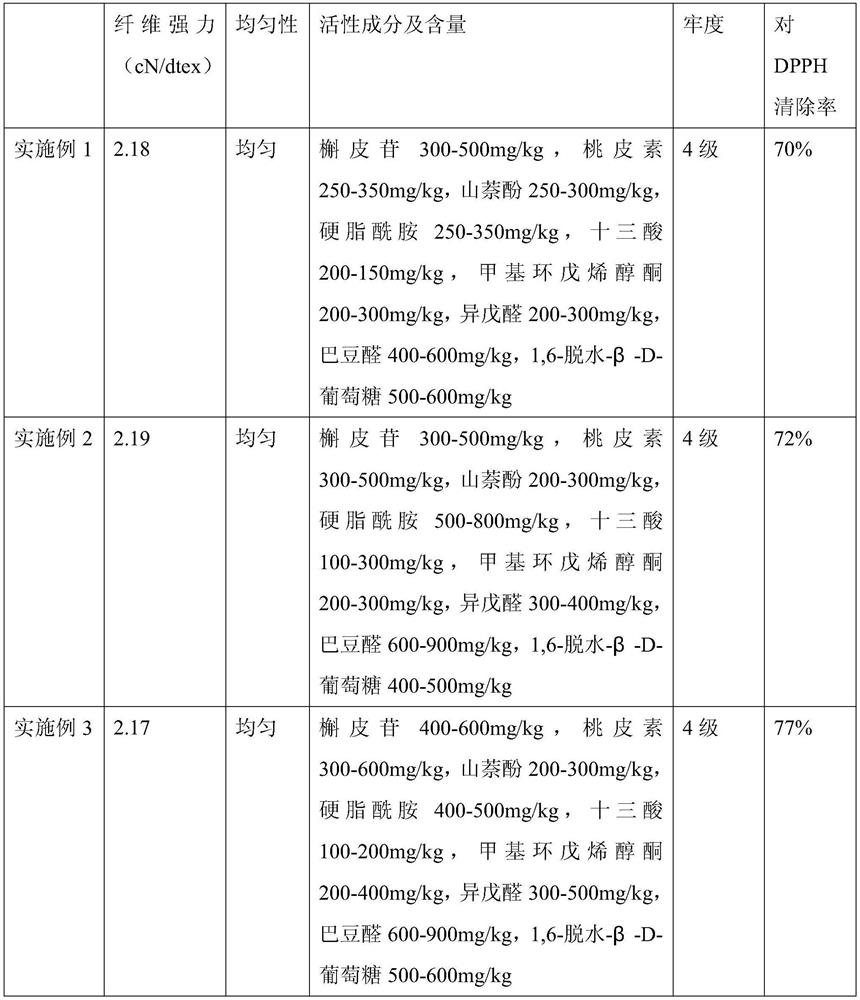

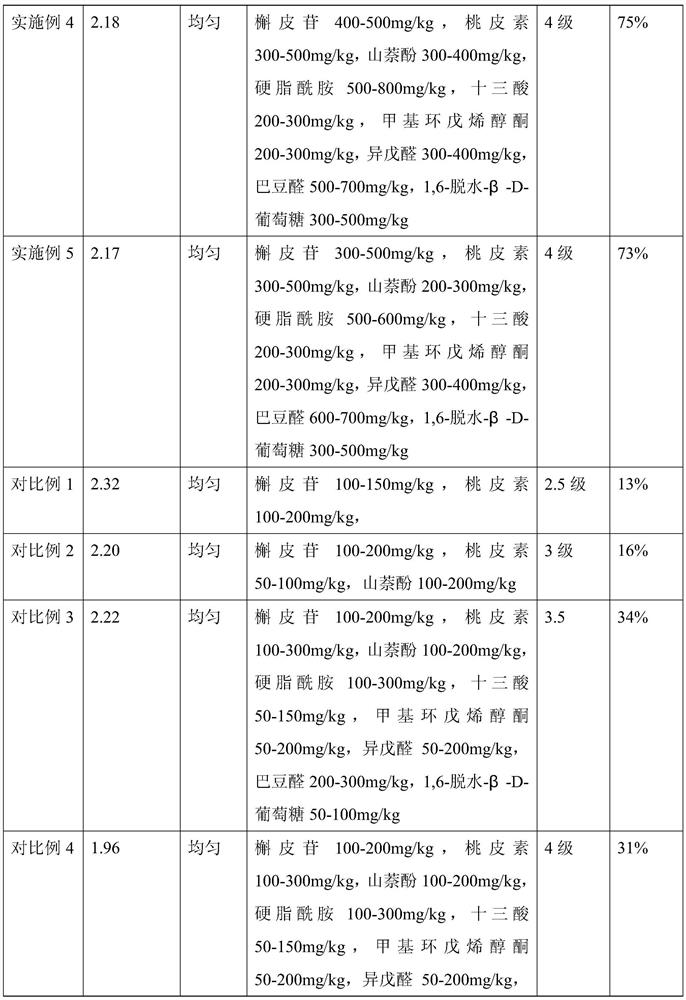

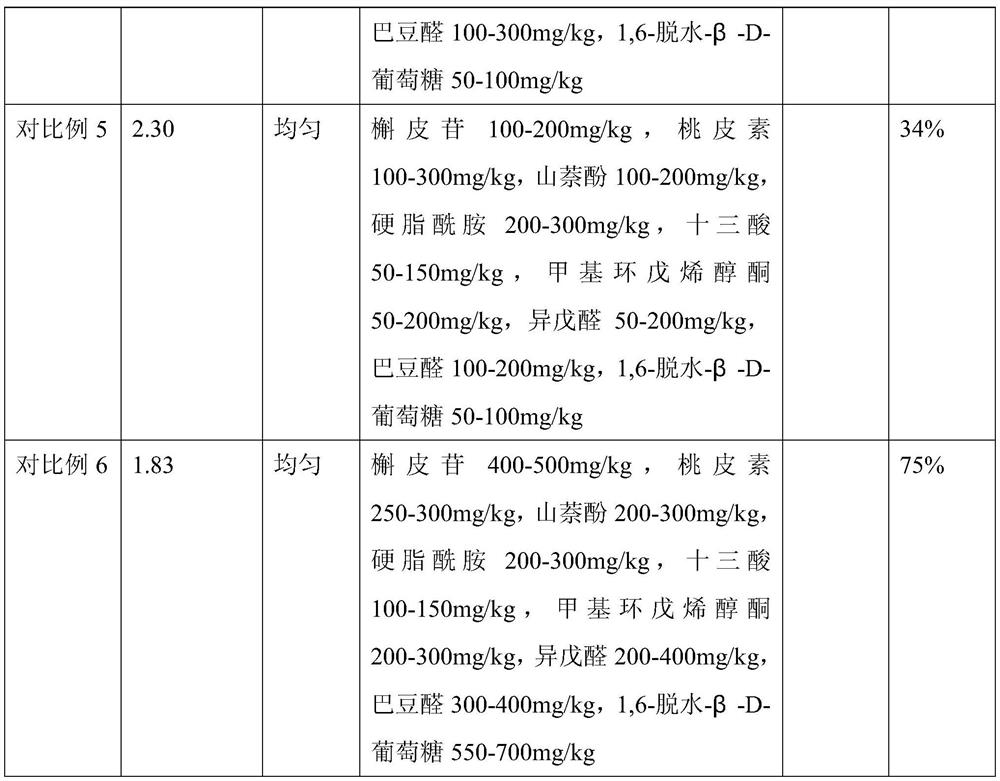

Examples

Embodiment 1

[0047] A kind of preparation technology of peach flower cellulose fiber, comprises the following steps:

[0048] S1. Extraction of peach blossom active substances:

[0049] Mix peach blossoms and ethanol at a solid-to-liquid ratio of 1:20, extract 3 times with ultrasonic waves at room temperature at 200w, and after extraction, evaporate and concentrate in a rotary evaporator, then vacuum-dry to obtain peach blossom extracts. The peach blossoms are fresh peach blossoms or dried peach blossoms;

[0050] S2, cellulose fiber pretreatment:

[0051] Cake the cellulose fibers, and then mix and soak them with the pretreatment solution at a ratio of 1:10. The pretreatment temperature is 60°C, the heating rate is 2°C / min, and the treatment time is 60min. The pretreatment solution is cationic quaternary ammonium salt poly A mixture of methyldiallylammonium chloride and NaOH; 1L of pretreatment liquid contains 15g of cationic quaternary ammonium salt and 12g of alkali;

[0052] S3, comp...

Embodiment 2

[0055] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0056] In step S2, the cationic quaternary ammonium salt contained in the pretreatment liquid is dioctadecyl dimethyl hydroxypropyl polyammonium chloride.

Embodiment 3

[0058] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0059] In step S2, the cationic quaternary ammonium salt contained in the pretreatment liquid is 3-chloro-2-hydroxypropyl-trimethylammonium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com