Flexible vibration sensor with piezoresistive effect and preparation method thereof

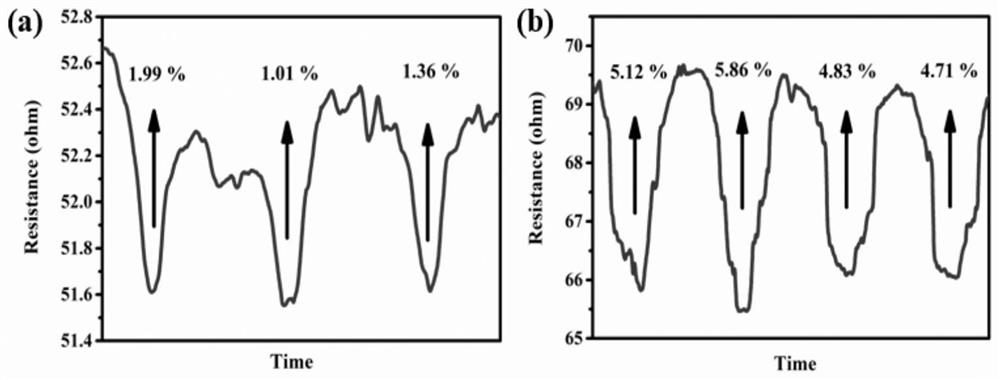

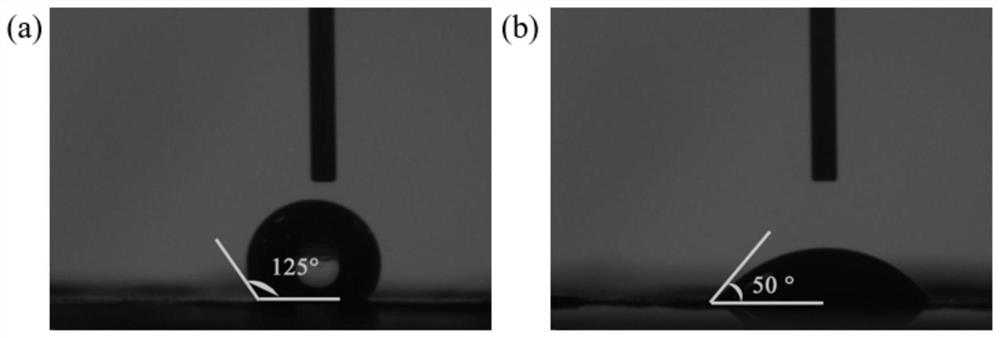

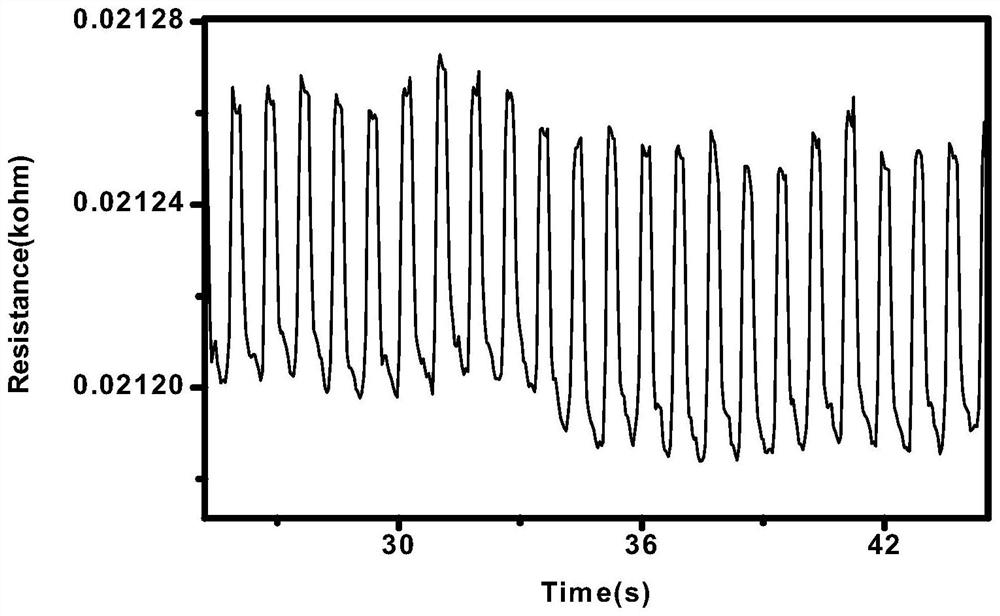

A vibration sensor, piezoresistive effect technology, applied in the measurement of the property force of piezoresistive materials, nanotechnology for sensing, instruments, etc. It can solve problems such as stretching and low sensitivity, and achieve the effect of enhancing piezoresistive effect, enhancing sensitivity, piezoresistive performance and environmental adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A kind of preparation method of the flexible vibration sensor with piezoresistive effect, it is characterized in that, comprises the following steps:

[0030] Step 1, preparing a carbon nanotube film with a thickness of 50 microns by chemical vapor deposition,

[0031] Step 2, using a plasma cleaning machine PT-2S to carry out plasma treatment on the carbon nanotube film obtained in step 1, the power is 300W, the air pressure is 10Pa, and the plasma treatment time is 10min to obtain a hydroxylated carbon nanotube film;

[0032] Step 3, using atomic layer deposition technology to deposit a zinc oxide layer on the carbon nanotube film treated in step 1 to obtain zinc oxide@carbon nanotube film; using diethyl zinc as the zinc source and deionized water as the oxygen source, deposit The temperature was 150°C and the number of cycles was 280. Among them, one cycle includes: diethyl zinc pulse 0.02s, nitrogen purge 8s (to remove the ethane generated by the reaction and dieth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thick bottom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com