Preparation method of copper-zinc-tin-germanium-selenium absorption layer film with germanium gradient

A copper, zinc, tin, germanium, selenium, and absorbing layer technology, applied in the field of new energy sources for optoelectronic materials, can solve problems such as not being able to meet the needs of thin-film batteries, and achieve the effects of improving carrier collection efficiency, improving performance, and good film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a copper-zinc-tin-germanium-selenium absorbing layer film with a germanium gradient, specifically comprising the following steps:

[0042] (1) Substrate pretreatment: Clean the soda-lime glass substrate with detergent powder and washing powder in turn, and then use acetone and alcohol to ultrasonically clean the sinking bottom. The ultrasonic time is 30 minutes, and then place the sinking bottom Soak in 0.4mol / L potassium dichromate for 8-10 hours, then use deionized water to ultrasonically clean for 30 minutes and dry the soda-lime glass with nitrogen for later use;

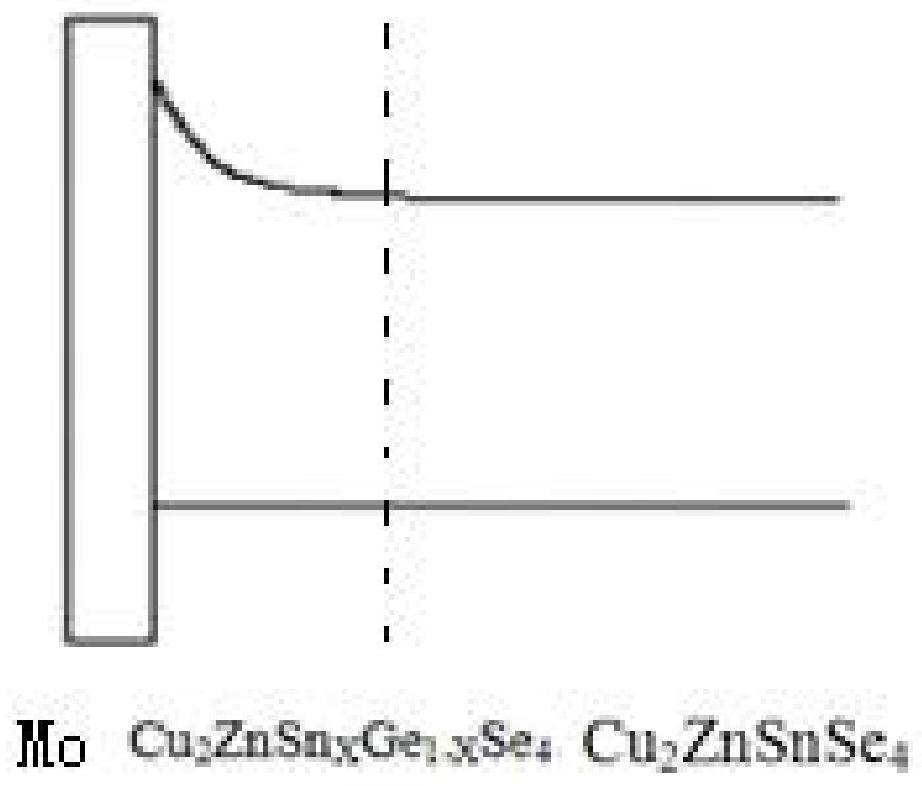

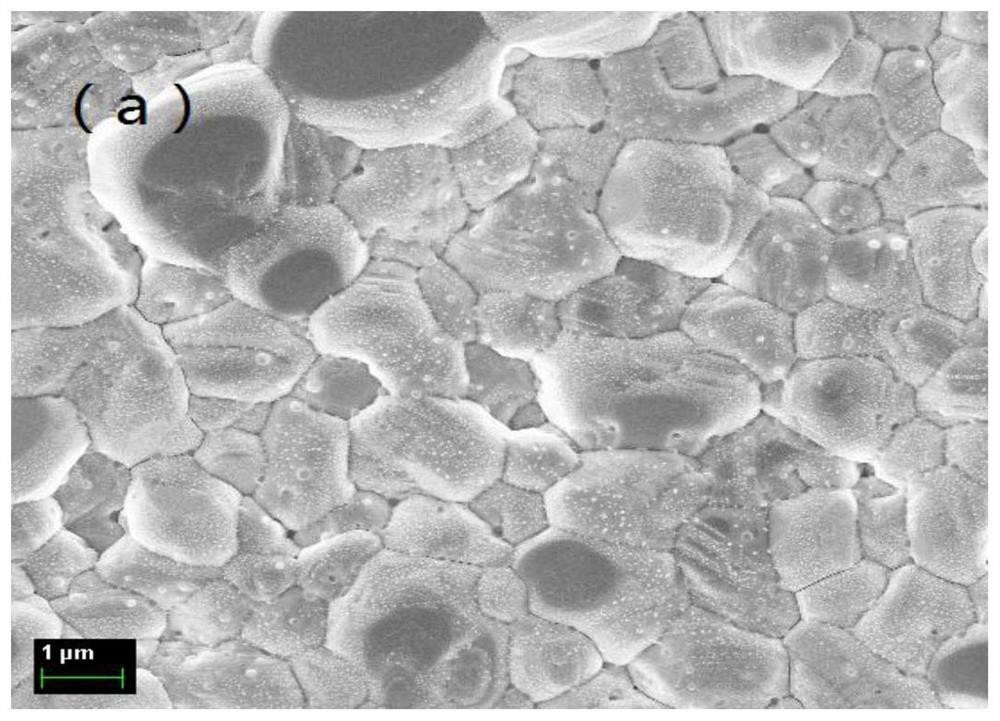

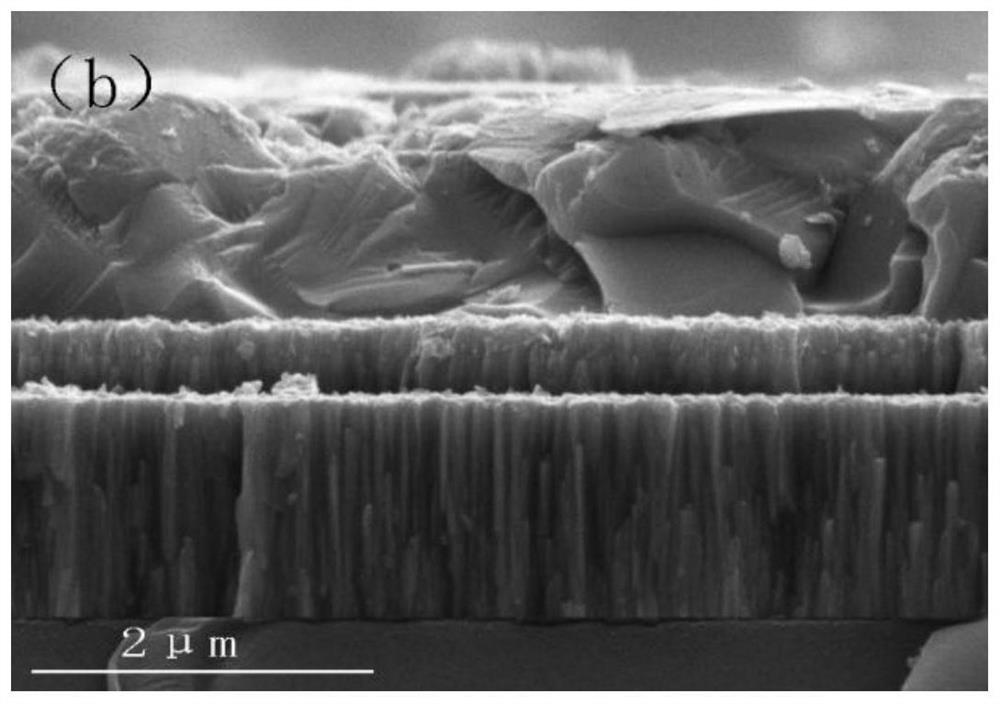

[0043] (2) Preparation of molybdenum layer and germanium layer: put the pretreated soda-lime glass into the magnetron sputtering system, first deposit the first molybdenum layer (back electrode layer) of 0.8 μm on the soda-lime glass, and then On the first molybdenum layer, a Ge layer is deposited by sputtering, the sputtering power of the Ge target is 25W, and the deposition time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com