Gastrointestinal anastomotic nail with degradable drug film layer and preparation method of gastrointestinal anastomotic nail

A technology for gastrointestinal anastomosis and staples, which is applied in the field of medical devices, can solve the problems of easy fracture of magnesium alloy wires, no corrosion resistance measures, and too fast degradation rate, so as to avoid rapid degradation and solve long-term retention problems. Problems and negative effects, the effect of promoting healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

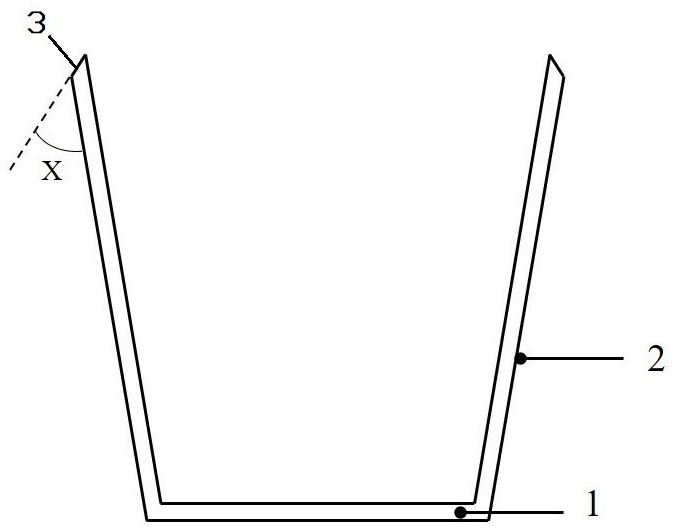

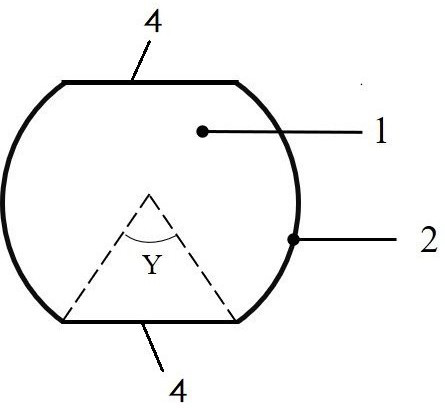

[0048] The preparation method of the gastrointestinal staple with degradable drug film of the present invention is as follows:

[0049] 1) Select a magnesium alloy ingot with a zinc content of 2wt% (the balance is magnesium and unavoidable impurities), and perform hot extrusion at 360°C with an extrusion ratio of 20:1 to obtain magnesium alloy bars;

[0050] 2) The magnesium alloy bar obtained in step 1) is subjected to multi-pass drawing deformation and annealed at 200°C to obtain a magnesium alloy wire with a diameter of 0.2mm;

[0051] 3) Perform precision hot rolling of the magnesium alloy wire obtained in step 2) at a rolling temperature of 100°C and a reduction ratio of 10% of the diameter to obtain a magnesium alloy wire with an elliptical cross-section;

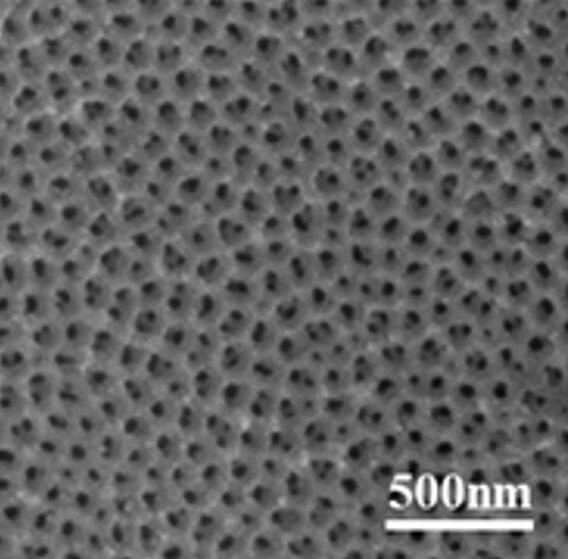

[0052] 4) Continuously anodize the magnesium alloy wire with elliptical cross-section obtained in step 3), and the treatment time per unit length of the wire is 10 minutes.

[0053] 5) Nail the magnesium alloy wire processed in...

Embodiment 2

[0058] The preparation method of the gastrointestinal staple with degradable drug film of the present invention is as follows:

[0059] 1) Select a magnesium alloy ingot with a zinc content of 2wt% (the balance is magnesium and unavoidable impurities), and perform hot extrusion at 380°C with an extrusion ratio of 20:1 to obtain magnesium alloy bars;

[0060] 2) The magnesium alloy bar obtained in step 1) is subjected to multi-pass drawing deformation and annealed at 250°C to obtain a magnesium alloy wire with a diameter of 0.2mm;

[0061] 3) Precisely hot-roll the magnesium alloy wire obtained in step 2) at a rolling temperature of 100°C and a reduction ratio of 15% of the diameter to obtain a magnesium alloy wire with an elliptical cross-section;

[0062] 4) Continuously anodize the magnesium alloy wire with elliptical cross-section obtained in step 3), and the treatment time per unit length of the wire is 10 minutes.

[0063] 5) Nail the magnesium alloy wire processed in step 4) to ob...

Embodiment 3

[0068] The preparation method of the gastrointestinal staple with degradable drug film of the present invention is as follows:

[0069] 1) Select a magnesium alloy ingot with a zinc element content of 2wt% and a calcium element content of 0.5% (the balance is magnesium and unavoidable impurities), and perform hot extrusion at 400°C with an extrusion ratio of 20:1. Obtain magnesium alloy bars;

[0070] 2) The magnesium alloy bar obtained in step 1) is subjected to multi-pass drawing deformation, and annealed at 270°C to obtain a magnesium alloy wire with a diameter of 0.3mm;

[0071] 3) Perform precision hot rolling of the magnesium alloy wire obtained in step 2) at a rolling temperature of 100°C and a reduction ratio of 18% of the diameter to obtain a magnesium alloy wire with an elliptical cross-section;

[0072] 4) Continuously anodize the magnesium alloy wire with elliptical cross-section obtained in step 3), and the treatment time per unit length of the wire is 10 minutes.

[0073]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com