Yeast organic zinc tooth powder composition and preparation method thereof

A technology of zinc tooth powder and composition, which is applied in the field of tooth powder composition and its preparation, can solve the problems of strong oral cavity and tooth irritation, low oral cavity and tooth irritation, and achieve low sensitivity and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0054] [Preparation Example 1] Yeast Organic Zinc

[0055]After culturing the yeast (manufacturer: Huonaling Biotechnology Company, model: BF-1688) at a temperature of 37°C and a humidity of 70% for 48 hours, the yeast was mixed with 0.1M zinc gluconate (manufacturer: Hengyi Co., Ltd., model: 667788) was reacted at a temperature of 39° C. for 2 hours to obtain yeast organozinc (average diameter of 3 to 4 μm, average length of 6 to 8 μm).

Embodiment 1

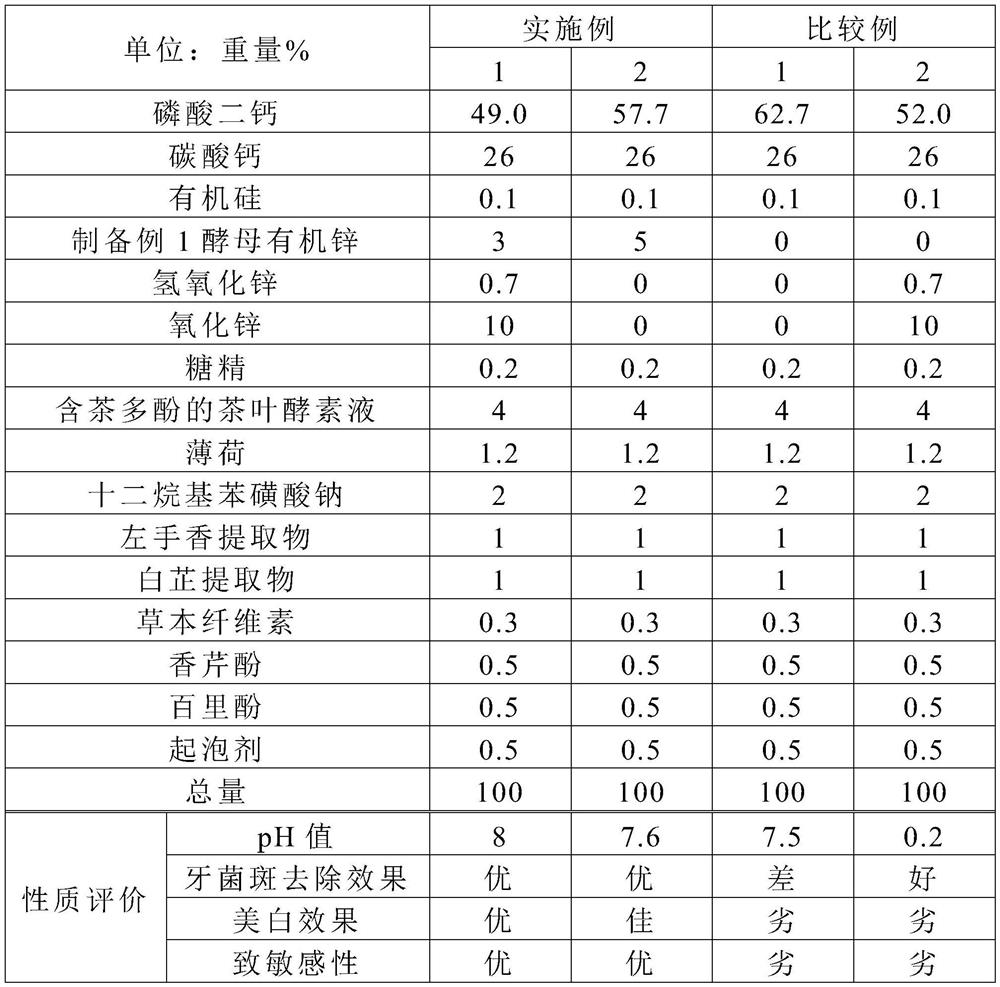

[0056] [Example 1] Yeast organic zinc tooth powder composition

[0057] (1). With 49.0% by weight of dicalcium phosphate (purchased from the first chemical industry, food grade), 26% by weight of calcium carbonate (purchased from the first chemical industry, food grade), and 0.1% by weight of organic silicon ( Manufacturer: Hengyi Co., Ltd., model: Si-001) mixed to obtain the first raw material.

[0058] (2). The yeast organozinc of preparation example 1, 10% by weight of zinc oxide (manufacturer: Huo Naling Biotechnology Company, model: ZnO-010) and 0.7% by weight of zinc hydroxide are mixed (manufacturer : Huo Naling Biotechnology Company, model: Zn-010), obtain the second raw material.

[0059] (3). 0.2% by weight of saccharin (manufacturer: Hengyi Co., Ltd., model: Su-080) is heated and dissolved in 4% by weight of tea enzyme liquid containing tea polyphenols (manufacturer: Huo Naling Biotechnology Company, model : Tea-55), a mixed solution was obtained. Then, the mixed...

Embodiment 2

[0063] [Example 2] Yeast Organic Zinc Tooth Powder Composition

[0064] (1). With 57.7% by weight of dicalcium phosphate (purchased from the first chemical industry, food grade), 26% by weight of calcium carbonate (purchased from the first chemical industry, food grade), and 0.1% by weight of organic silicon ( Manufacturer: Hengyi Co., Ltd., model: Si-001) mixed to obtain the first raw material.

[0065] (2). 5% by weight of yeast organozinc in Preparation Example 1 was used as the second raw material.

[0066] (3). 0.2% by weight of saccharin (manufacturer: Hengyi Co., Ltd., model: Su-080) was heated and dissolved in 4% by weight of tea enzyme solution (manufacturer: Huo Naling Biotechnology Company, model: Tea-55) , a mixed solution was obtained. Then, the mixture was mixed with 1.2% by weight of mint (manufacturer: Hengyi Co., Ltd., model: 7788009) using a sprayer to obtain a third raw material.

[0067] (4). The first raw material and the second raw material are placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com