304 stainless steel pickling passivation agent and preparation method thereof

A technology of 304 stainless steel and passivating agent, which is applied in the coating process of metal materials, etc., can solve the problems of high cost, stainless steel hazards, high labor intensity, etc., and achieve the effect of mild nature and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

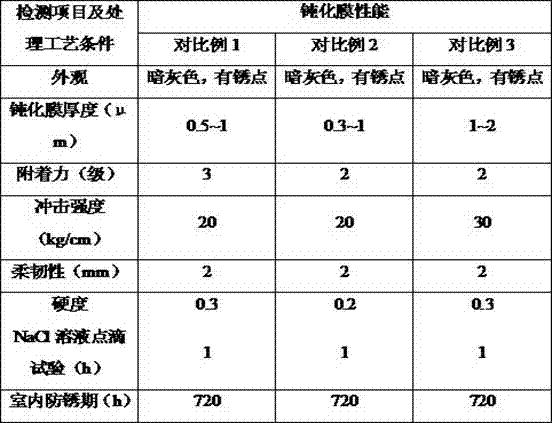

Examples

Embodiment 1

[0016] A pickling passivator for 304 stainless steel, comprising the following components in parts by weight: 1 part of magnesium stearate, 0.1 part of ferric chloride, 1 part of fluorosilicic acid, 1 part of fatty alcohol polyoxyethylene ether sodium sulfate, coconut oil 0.5 part of amidopropyl amine oxide, 0.2 part of triethanolamine, 0.1 part of urotropine, 0.1 part of epoxy octyl stearate, 5 parts of water.

[0017] Magnesium stearate, ferric chloride, fluosilicic acid, sodium fatty alcohol polyoxyethylene ether sulfate, cocamidopropyl amine oxide, triethanolamine, hexamethylene, epoxy octyl stearate, and water in proportion Add it into the reaction kettle, raise the temperature to 40~50°C, stir and mix evenly, and get 304 stainless steel pickling passivation agent.

Embodiment 2

[0019] A pickling passivator for 304 stainless steel, comprising the following components in parts by weight: 2 parts of magnesium stearate, 0.4 part of ferric chloride, 2 parts of fluorosilicic acid, 2 parts of fatty alcohol polyoxyethylene ether sodium sulfate, coconut oil 0.8 parts of amidopropyl amine oxide, 0.3 parts of triethanolamine, 0.5 parts of urotropine, 0.7 parts of epoxy octyl stearate, and 15 parts of water.

[0020] Magnesium stearate, ferric chloride, fluosilicic acid, sodium fatty alcohol polyoxyethylene ether sulfate, cocamidopropyl amine oxide, triethanolamine, hexamethylene, epoxy octyl stearate, and water in proportion Add it into the reaction kettle, raise the temperature to 40~50°C, stir and mix evenly, and get 304 stainless steel pickling passivation agent.

Embodiment 3

[0022] A pickling passivator for 304 stainless steel, comprising the following components in parts by weight: 1.5 parts of magnesium stearate, 0.3 parts of ferric chloride, 1.5 parts of fluorosilicic acid, 1.5 parts of fatty alcohol polyoxyethylene ether sodium sulfate, coconut oil 0.6 parts of amidopropyl amine oxide, 0.2 parts of triethanolamine, 0.4 parts of urotropine, 0.5 parts of epoxy octyl stearate, 12 parts of water.

[0023] Magnesium stearate, ferric chloride, fluosilicic acid, sodium fatty alcohol polyoxyethylene ether sulfate, cocamidopropyl amine oxide, triethanolamine, hexamethylene, epoxy octyl stearate, and water in proportion Add it into the reaction kettle, raise the temperature to 40~50°C, stir and mix evenly, and get 304 stainless steel pickling passivation agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com