Completely biodegradable polyester blend and preparation method thereof

A biodegradable polyester and blend technology, applied in the field of degradable materials, can solve the problems of poor impact toughness, limited wide application, difficult to meet, etc., to improve toughness and barrier properties, good toughness and barrier properties, performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1PBSF

[0026] Add 1,4-butanediol, tetrabutyl titanate, 2,5-furandicarboxylic acid, and succinic acid into the reaction flask, and 1,4-butanediol and total dibasic acid (2,5-furan The molar ratio of dicarboxylic acid and succinic acid) is 3:1, and the molar ratio of 2,5-furandicarboxylic acid to succinic acid is 3:2. Tetrabutyl titanate is 5‰ of the mass of 2,5-furandicarboxylic acid. Nitrogen was blown, at 230°C, mechanically stirred, and reacted for 3 hours. Vacuumize afterwards, react for 5 hours, stop the reaction, and obtain the product.

Embodiment 2

[0027] The preparation of embodiment 2PBAF

[0028] Add 1,4-butanediol, tetrabutyl titanate, 2,5-furandicarboxylic acid, adipic acid into the reaction flask, 1,4-butanediol and total dibasic acid (2,5-furan The molar ratio of dicarboxylic acid to adipic acid) is 3:1, and the molar ratio of 2,5-furandicarboxylic acid to adipic acid is 3:2. Tetrabutyl titanate is 5‰ of the mass of 2,5-furandicarboxylic acid. Nitrogen was blown, at 230°C, mechanically stirred, and reacted for 3 hours. Vacuumize afterwards, react for 5 hours, stop the reaction, and obtain the product.

Embodiment 3

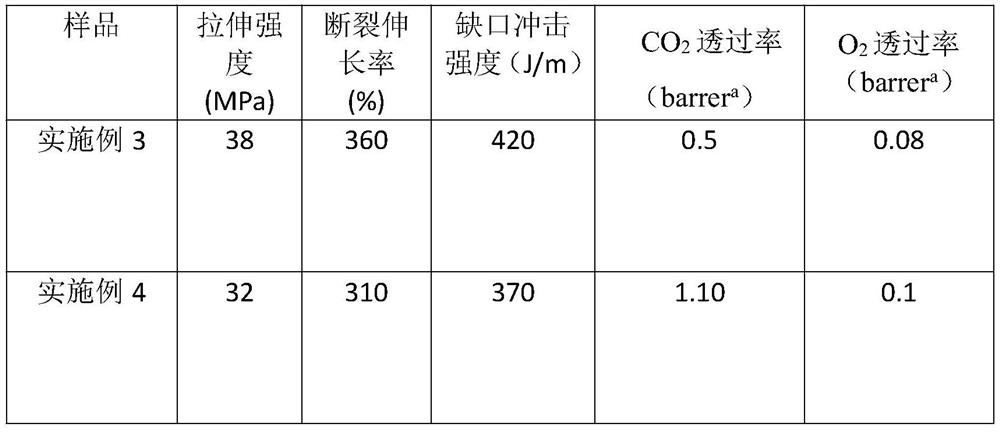

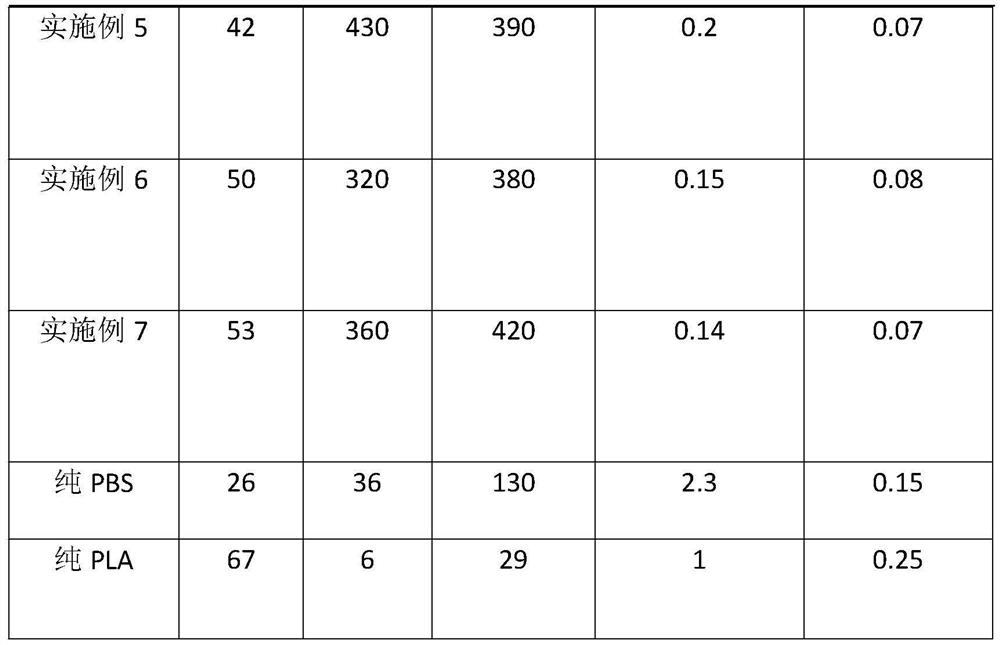

[0030] After weighing PBS and the polyester prepared in Example 2 according to the mass ratio of 4:1, mix them in a mixer at room temperature for 10 minutes, then add them to an extruder, heat them to extrude and granulate, and the extruder and injection molding machine The temperature is 170°C, and the finished product is obtained.

[0031] The properties of the product prepared in Example 3 are shown in Table 1, wherein the tensile properties are tested according to GB / T 1040-92, using type I splines, and the tensile speed is 50mm / min; the impact properties are tested according to ASTM D256.

[0032] Measured by Labthink VAC-V2 gas permeation tester, the temperature is 23°C, the humidity is 50%, the diameter of the film is 97mm, and the test area is 38.5cm 2 , the average value of three tests was taken, and the oxygen and carbon dioxide transmission rates of the film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com