Sodium-carbon dioxide battery, anode for sodium-based battery and preparation method of sodium-carbon dioxide battery

An anode and battery technology, applied in the field of new energy materials, can solve problems such as large contact interface resistance, internal short circuit, safety issues, etc., and achieve the effects of stable electrochemical performance, large specific surface area, and increased conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] This specific embodiment also includes the above-mentioned preparation method for the anode on the sodium-based battery, comprising the following steps:

[0030] S1. Dissolving the supporting electrolyte in an ether solvent to prepare an electrolyte solution with a concentration of 0.1 to 1 mol / L; the supporting electrolyte includes sodium perchlorate, sodium trifluoromethanesulfonate, sodium bistrifluoromethanesulfonylimide, One or more of sodium hexafluorophosphate;

[0031] S2, dissolving biphenyl and metal sodium in the electrolyte solution in step S1 to obtain an alkali solution with a sodium concentration of 0.1-1mol / L;

[0032] S3. Add conductive carbon to the alkali solution prepared in step S2 according to 0.1-5% of the mass fraction of the alkali solution and stir for 2-3 hours to obtain the anode.

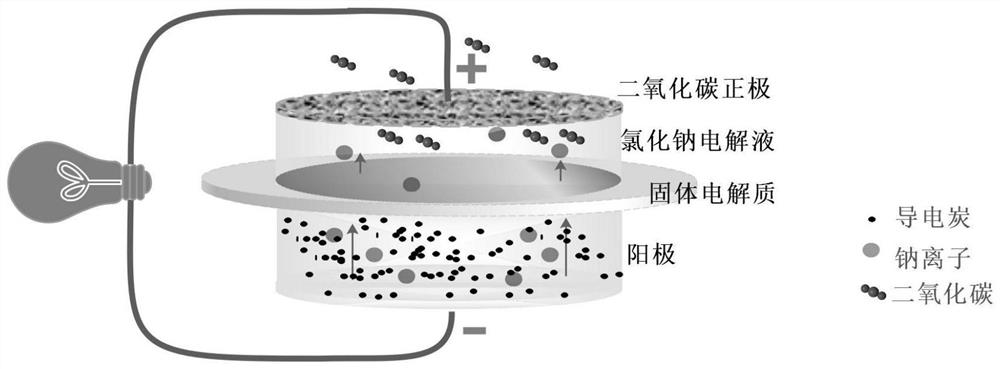

[0033] combine figure 1 , this specific embodiment also includes a sodium carbon dioxide battery, which includes the above-mentioned anode or the above-mentione...

Embodiment 1

[0038] In an inert atmosphere glove box, first use sodium perchlorate as a supporting electrolyte and dissolve it in tetraethylene glycol dimethyl ether, and stir until the supporting electrolyte is completely dissolved to obtain a 0.1mol / L sodium perchlorate electrolyte; : 1 Take biphenyl and sodium metal respectively, first dissolve biphenyl in the above-mentioned sodium perchlorate electrolyte, add sodium metal after dissolving completely to obtain 0.1mol / L dark green alkali solution, add 1wt after all dissolving % conductive carbon black, stirred for 2 hours to obtain a semi-liquid anode.

[0039] Such as figure 1 As shown, from the negative electrode to the positive electrode, the semi-liquid anode, β-Al 2 o 3 A sodium-aluminate fast ion conductor solid electrolyte, a sodium chloride electrolyte, and a carbon dioxide positive electrode are used to assemble a sodium-carbon dioxide battery.

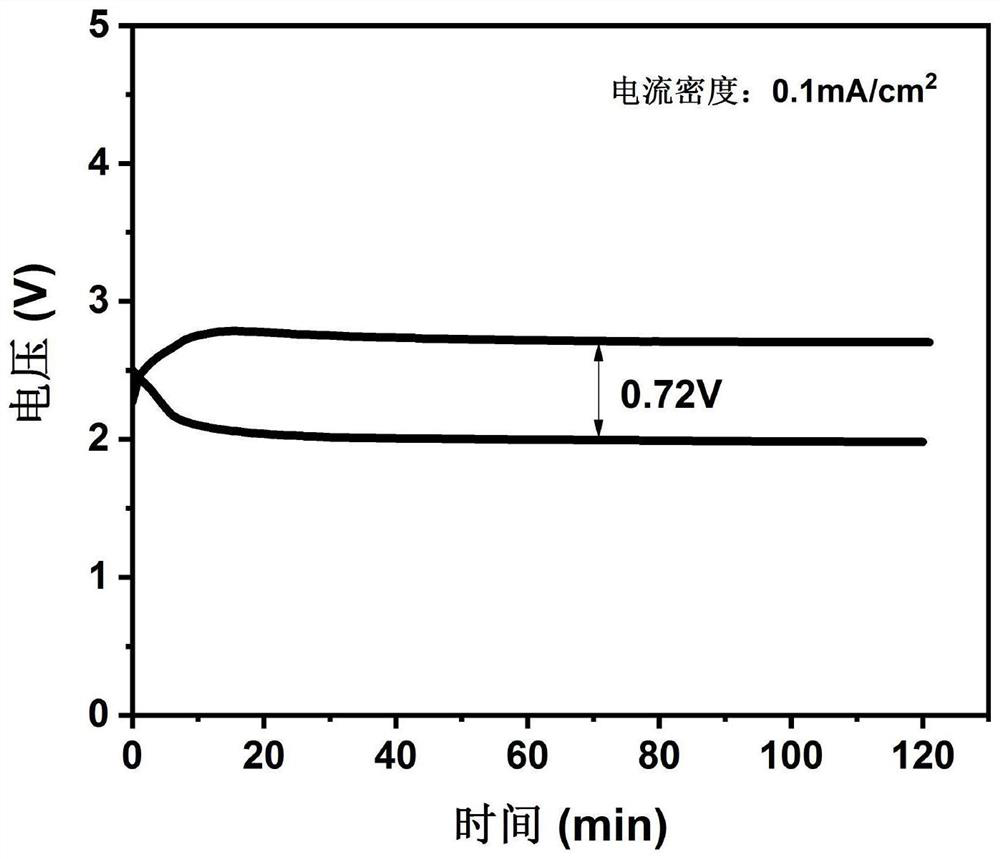

[0040] The sodium carbon dioxide battery assembled in this example is pure CO a...

Embodiment 2

[0042] In an inert atmosphere glove box, at first take sodium perchlorate as supporting electrolyte and be dissolved in ethylene glycol dimethyl ether, stir until supporting electrolyte is all dissolved, obtain the sodium perchlorate electrolyte of 0.1mol / L; Molar ratio 1: 1 Weigh biphenyl and metal sodium respectively, first dissolve biphenyl in the above-mentioned sodium perchlorate electrolyte, and then add metal sodium to obtain a 1mol / L dark green alkali solution after completely dissolving, then add 5wt% of Conductive carbon black, stirred for 2 hours, can obtain double (electronic and ion) conductive medium semi-liquid anode.

[0043] Such as figure 1 As shown, from the negative electrode to the positive electrode, the sodium carbon dioxide battery is assembled sequentially from the bottom to the top according to the semi-liquid anode, the sulfide fast ion conductor solid electrolyte, the sodium chloride electrolyte, and the carbon dioxide positive electrode.

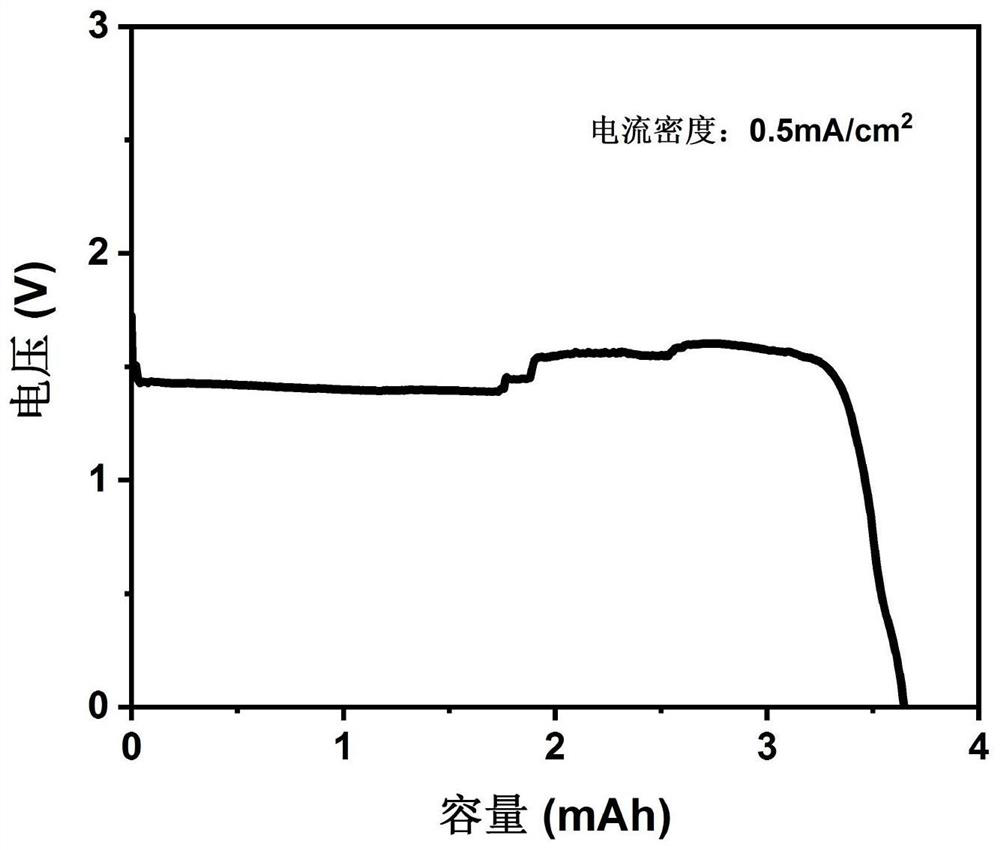

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com