Flue gas recirculation oxygen-enriched incineration sludge and muddy water cooperative treatment method

A technology of flue gas recirculation and sludge incineration, applied in water/sludge/sewage treatment, biological water/sewage treatment, combustion methods, etc., can solve the NIMBY effect and the unfavorable development of the sludge drying and incineration technology route. factors, the large amount of flue gas generated, etc., to achieve the effect of reducing treatment costs, reducing the difficulty of flue gas treatment, and reducing nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

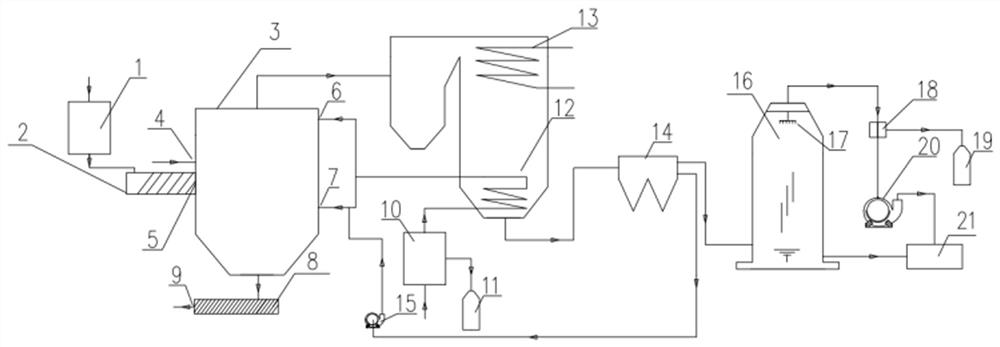

[0023] In order to make the present invention more comprehensible, in conjunction with the accompanying drawings, the preferred embodiments are further described as follows.

[0024] Such as figure 1 As shown, a flue gas recirculation oxygen-enriched incineration sludge and mud-water co-processing system includes a sludge feeding device 2, an oxygen-enriched fluidized bed incinerator 3, an oxygen generating device 10, a flue gas treatment device, and carbon dioxide capture device 18, characterized in that

[0025] The oxygen-enriched fluidized bed incinerator 3 includes a sludge inlet 5, an auxiliary fuel inlet 4, an air inlet, and an air outlet positioned at the top of the oxygen-enriched fluidized bed incinerator, and the sludge inlet passes through a sludge feeding device and The wet sludge receiving bin is connected, the air outlet is connected to the waste heat boiler, and a primary air preheater is installed in the waste heat boiler, and the air inlet is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com