MicroLED preparation method based on three-dimensional mask substrate

A mask and three-dimensional technology, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of time-consuming, small size of Micro LED, and shift of light emission wavelength, and achieve the goals of solving wavelength drift, improving detection efficiency, and low defect density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

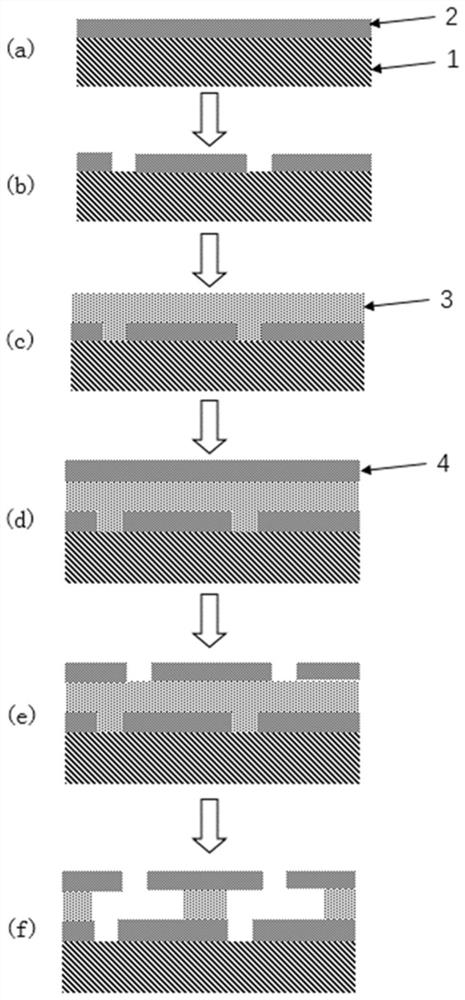

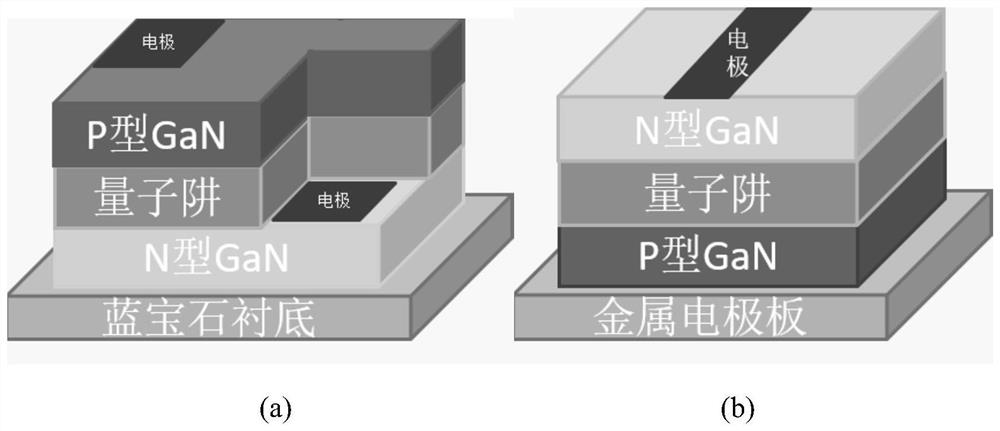

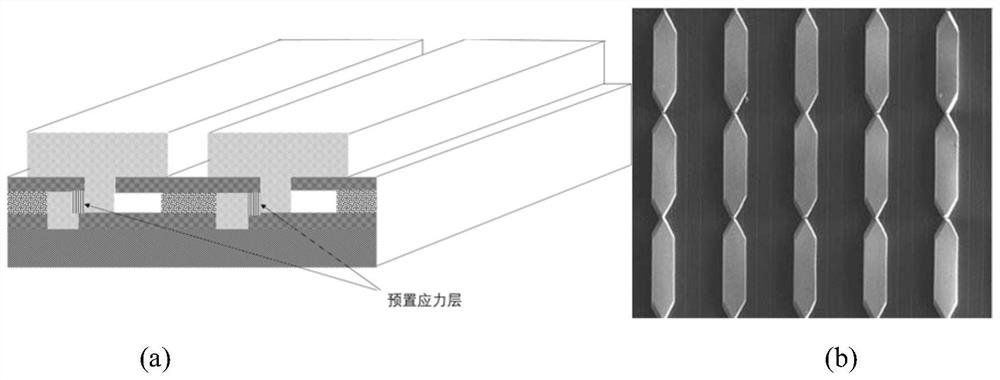

[0046] In order to make the above objects, features and advantages of the present invention more obvious and easy to understand, the present invention will be further described in detail below by taking GaN among III-nitride materials as an example through specific embodiments and accompanying drawings.

[0047] In the present invention, the three-dimensional mask substrate technology used can firstly provide GaN materials with ultra-high crystal quality for the device structure epitaxy of Micro LEDs, thereby solving the demand for high crystal quality in Micro LEDs and overcoming many problems caused by insufficient crystal quality. caused problems. In the second aspect, the three-dimensional mask technology has the characteristics of easy peeling, and the peeled monomer has small protrusions, which is convenient for absorbing and grabbing MicroLEDs during the mass transfer process, which can well meet the needs of MicroLEDs for easy peeling and transfer. . In the third aspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com