Organic-inorganic hybrid perovskite powder and preparation method and application thereof

A perovskite and inorganic technology, applied in the field of organic-inorganic hybrid perovskite powder and its preparation, can solve the problem that the aging of the perovskite precursor mixture cannot be effectively controlled, the composition of the perovskite powder is single, and the stability needs to be improvement and other problems, to achieve the effects of controllable stoichiometric ratio, high repeatability of film quality, and improved optoelectronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

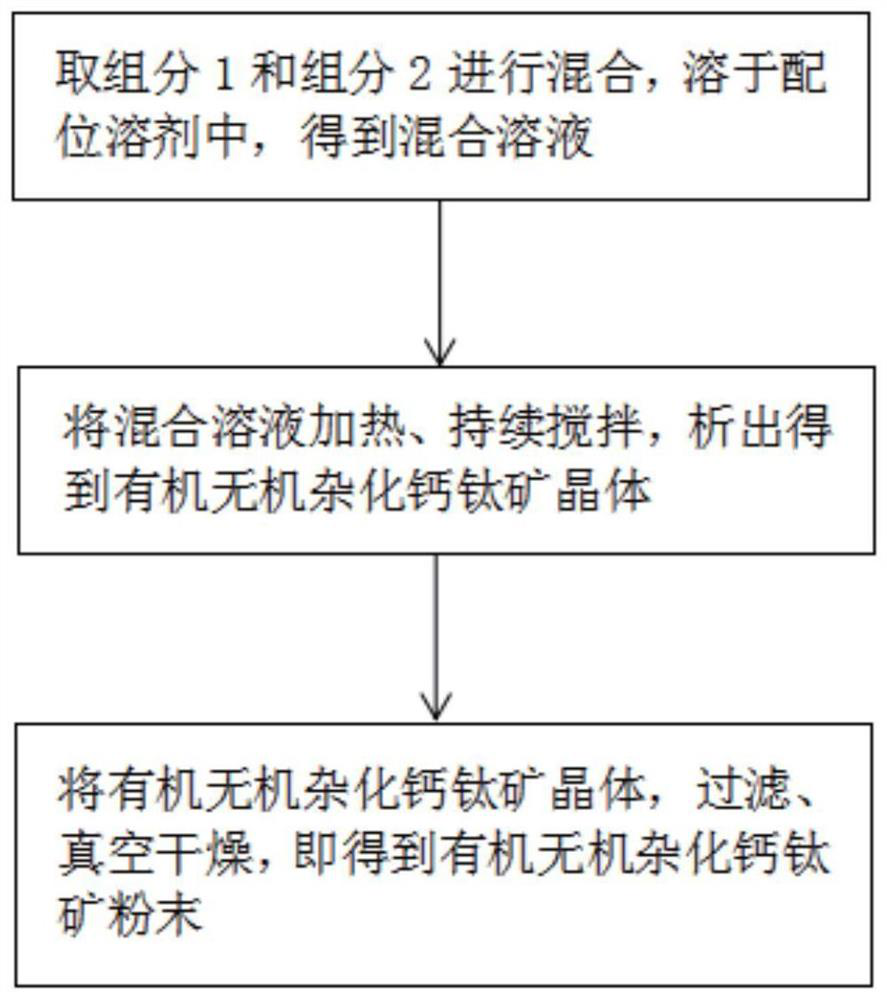

Method used

Image

Examples

Embodiment 1

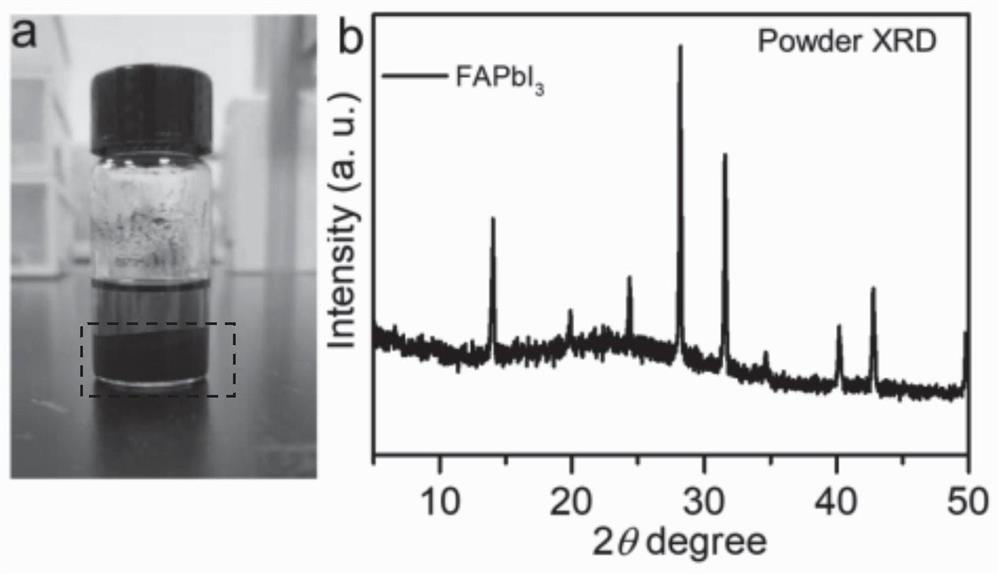

[0037] (1) 1 mmol FAI (formamidine iodide; HC (NH 2 ) 2 1) and 1.05mmol PbI 2 (Lead iodide) was dissolved in 0.5-2mL diethanol methyl ether solvent, and stirred continuously for 1h to obtain a mixed solution, which was then transferred to a round-bottomed flask.

[0038] (2) Place the above-mentioned round-bottomed flask in an oil bath at 80-120° C., and keep stirring. After 10-120 minutes of reaction, black organic-inorganic hybrid perovskite crystals FAPbI precipitated at the bottom of the round-bottomed flask 3 .

[0039] (3) The organic-inorganic hybrid perovskite crystal FAPbI obtained by precipitation 3 Filter to remove the diethanol methyl ether, dry the residual solvent on the surface of the crystal with filter paper, and dry it in a vacuum oven at 120°C to obtain the organic-inorganic hybrid perovskite powder FAPbI of this example 3 . The yield is calculated to be 80-90%.

[0040] (4) the organic-inorganic hybrid perovskite powder FAPbI of the present embodimen...

Embodiment 2

[0046] (1) 1mmol MAI (methylamine iodide; CH 3 NH 3 1) and 1.05mmol PbI 2 (Lead iodide) was dissolved in 1-2 mL of ethanolamine solvent, and stirred continuously for 1 h to obtain a mixed solution, which was then transferred to a round-bottomed flask.

[0047] (2) Place the above-mentioned round-bottomed flask in an oil bath at 80-120° C., and keep stirring. After 10-120 minutes of reaction, black organic-inorganic hybrid perovskite crystal MAPbI precipitated at the bottom of the round-bottomed flask 3 .

[0048] (3) The organic-inorganic hybrid perovskite crystal MAPbI obtained by precipitation 3 Filter to remove ethanolamine, dry the residual solvent on the crystal surface with filter paper, and dry in a vacuum oven at 120°C to obtain the organic-inorganic hybrid perovskite powder MAPbI of this example 3 . The yield is calculated to be 80-90%.

[0049] (4) the organic-inorganic hybrid perovskite powder MAPbI of the present embodiment 3 Dissolve in a mixed solution of...

Embodiment 3

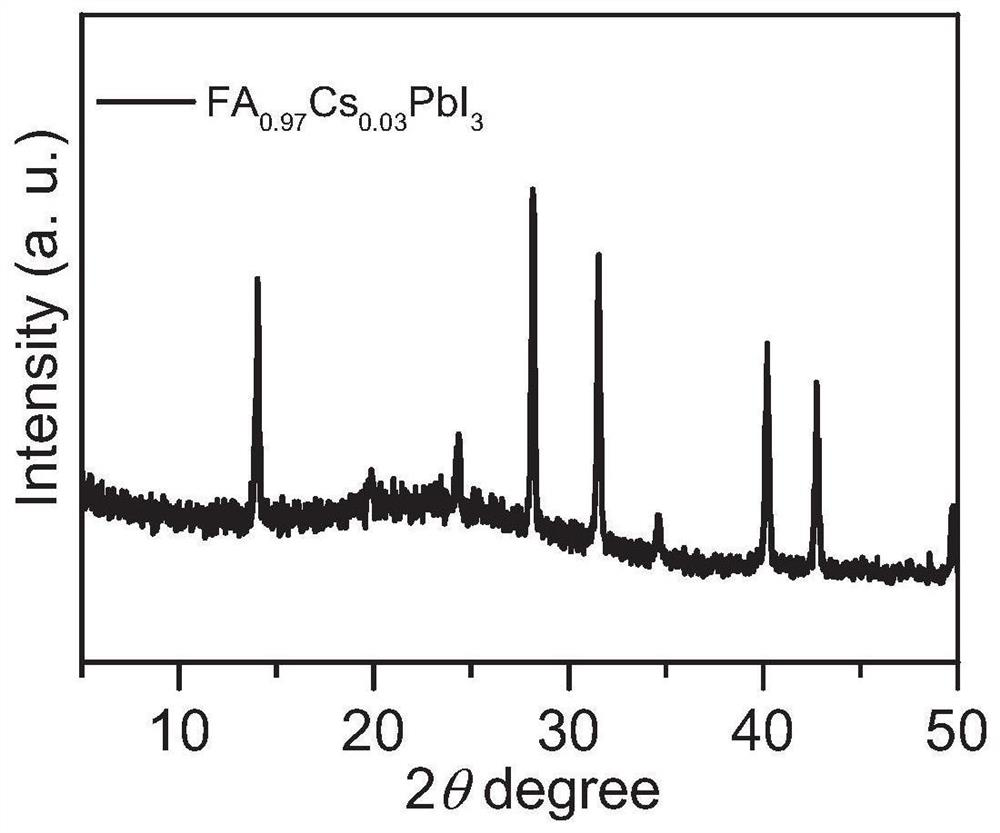

[0052] (1) Mix 1mmol FAI (formamidine iodide) and 1.05mmol PbI 2 (Lead iodide) was dissolved in 1-2 mL of dimethyl carbonate solvent, and stirred continuously for 1 h to obtain a mixed solution, which was then transferred to a round-bottomed flask.

[0053] (2) Place the above-mentioned round-bottomed flask in an oil bath at 80-120° C., and keep stirring. After 10-120 minutes of reaction, black organic-inorganic hybrid perovskite crystals FAPbI precipitated at the bottom of the round-bottomed flask 3 .

[0054] (3) The organic-inorganic hybrid perovskite crystal FAPbI obtained by precipitation 3 Filter to remove dimethyl carbonate, dry the residual solvent on the crystal surface with filter paper, and dry in a vacuum oven at 120°C to obtain the organic-inorganic hybrid perovskite powder FAPbI of this example 3 . The yield is calculated to be 80-90%.

[0055] (4) the organic-inorganic hybrid perovskite powder FAPbI of the present embodiment 3 Dissolve in a mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com