Efficient oxygen evolution electrocatalyst and preparation method thereof

An electrocatalyst and oxygen evolution technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

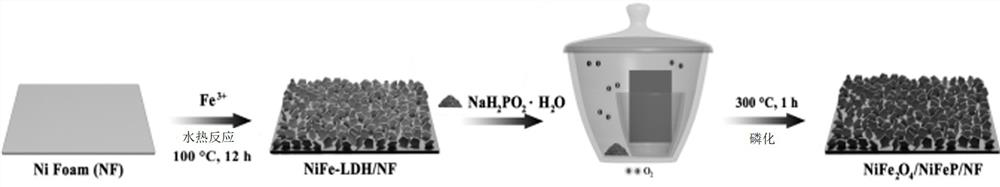

[0028] In this example, nickel foam (NF) was cut into a size of 2 cm × 3 cm × 1 mm. The preparation method of the high-efficiency oxygen evolution electrocatalyst in this example includes the synthesis of NiFe-LDH on NF and the synthesis of NiFe-LDH on NF 2 o 4 / NiFeP synthesis.

[0029] 1) Synthesis of NiFe-LDH on NF;

[0030] NiFe-LDH grown on NF was synthesized by hydrothermal method. NF was used after sequential ultrasonic cleaning in ethanol, deionized water, acetone, deionized water, HCl solution (pH 3) and deionized water for 15 minutes. First, 7.5 mmol urea and 0.375 mmol Fe(NO 3 ) 3 ∙9H 2O was dissolved in 30 mL deionized water and stirred for 3 h. The resulting solution was sonicated for 3 min and transferred to a 50 mL Teflon-lined stainless steel autoclave, and the cleaned NF was immersed in it. Then seal the autoclave, heat at 100° C. for 12 h, and cool to room temperature naturally after the reaction. Finally, it was washed three times in deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com