Beneficiation method for recycling sulfur and gold from cyaniding tailings

A technology of cyanide tailings and ore dressing method, applied in flotation, solid separation, etc., can solve the problems of high cost, waste of resources, low recovery rate of sulfur and gold elements, etc., achieve high recovery rate, ensure recovery rate, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

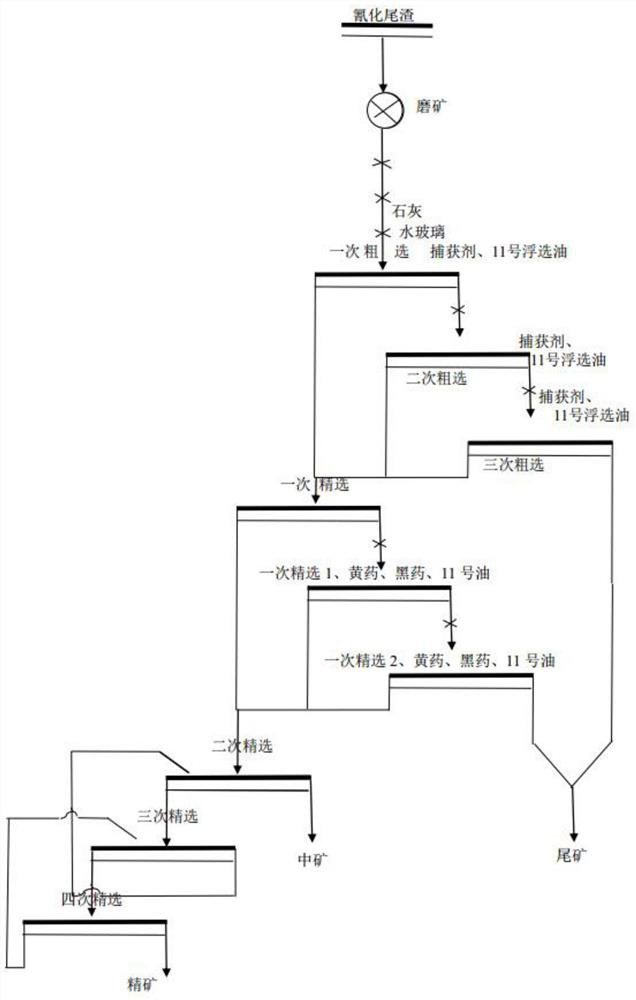

[0048] Such as figure 1 As shown, the present embodiment provides a kind of beneficiation method of reclaiming sulfur gold from cyanide tailings, comprising the following steps:

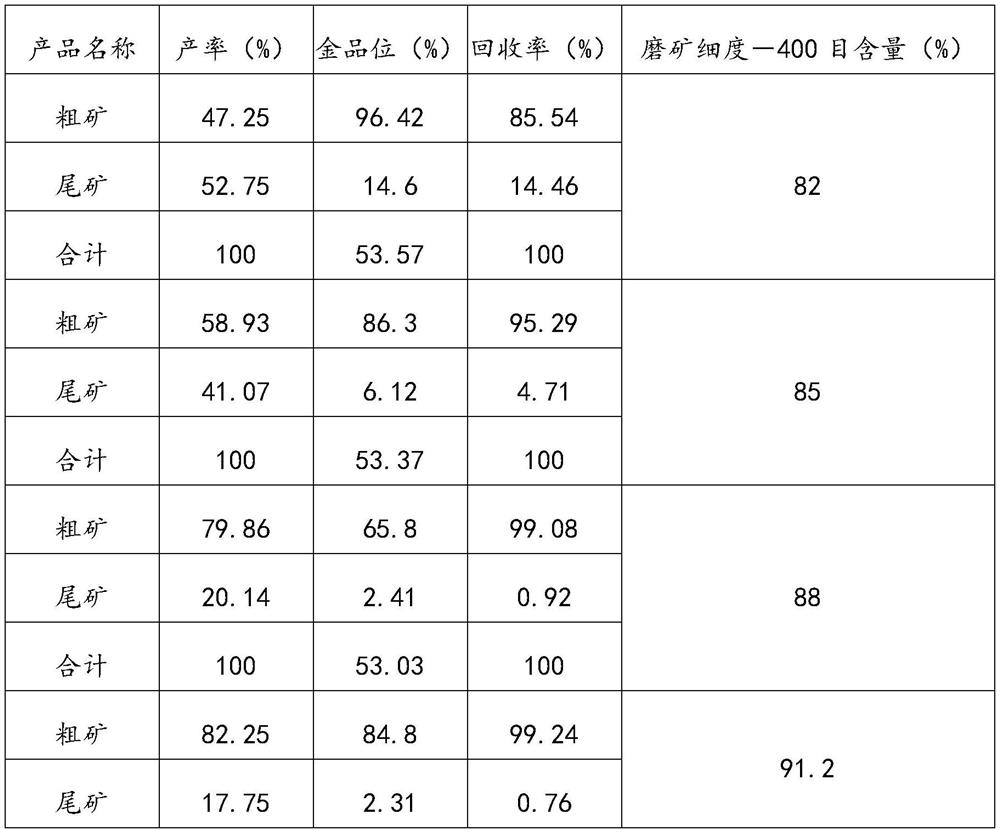

[0049] S1. Take the cyanide tailings composed of pyrite, hematite, galena, quartz, muscovite or albite, and grind the cyanide tailings with a ball mill for 30 minutes to obtain crushed ore. The grinding fineness of the crushed ore material is 400 mesh, and the ratio of slag to the total mass is 88%.

[0050] S2. Add lime to the crushed ore obtained in step S1 at a ratio of 0.82kg / t, stir for 1 minute after adding, then add water glass at a ratio of 1.5kg / t, stir for 30min, check the pH value, and then add sulfuric acid to adjust pH, adjusted to a pH value of 6.5, stirring to prepare a slurry with a concentration of 35%.

[0051]S31, add xanthate in the ratio of 600g / t to the pulp obtained in step S2, get the required xanthate and mix it with water to make a solution of xanthate with a concentration...

Embodiment 2

[0062] Such as figure 1 As shown, the present embodiment provides a kind of beneficiation method of reclaiming sulfur gold from cyanide tailings, comprising the following steps:

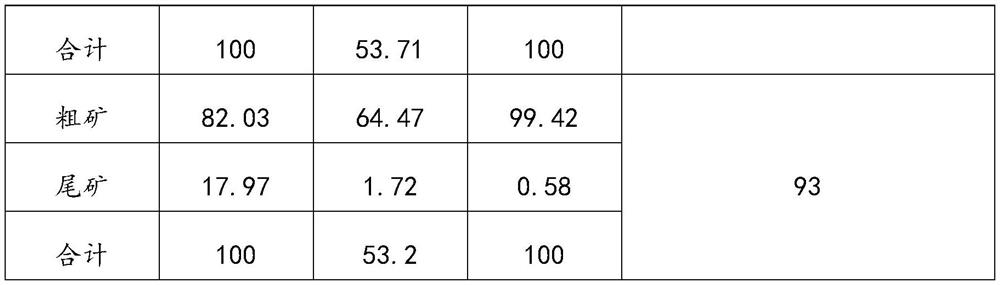

[0063] S1. Take the cyanide tailings composed of pyrite, hematite, galena, quartz, muscovite or albite, and grind the cyanide tailings with a ball mill for 30 minutes to obtain crushed ore. The grinding fineness of the crushed ore material is 400 mesh, and the ratio of slag to the total mass is 93%.

[0064] S2. Add lime to the crushed ore obtained in step S1 at a ratio of 0.82kg / t, stir for 1 minute after adding, then add water glass at a ratio of 1.5kg / t, stir for 30min, check the pH value, and then add sulfuric acid to adjust pH, adjusted to a pH value of 6.5, stirring to prepare a slurry with a concentration of 35%.

[0065] S31. Add xanthate in the ratio of 900g / t to the pulp obtained in step S2, mix the required xanthate with water to prepare xanthate solution with a concentration of 5%, take...

Embodiment 3

[0076] Such asfigure 1 As shown, the present embodiment provides a kind of beneficiation method of reclaiming sulfur gold from cyanide tailings, comprising the following steps:

[0077] S1. Take the cyanide tailings composed of pyrite, hematite, galena, quartz, muscovite or albite, and grind the cyanide tailings with a ball mill for 30 minutes to obtain crushed ore. The grinding fineness of the crushed ore material is 400 mesh, and the ratio of slag to the total mass is 90%.

[0078] S2. Add lime to the crushed ore obtained in step S1 at a ratio of 0.82kg / t, stir for 1 minute after adding, then add water glass at a ratio of 1.5kg / t, stir for 30min, check the pH value, and then add sulfuric acid to adjust pH, adjusted to a pH value of 6.5, stirring to prepare a slurry with a concentration of 35%.

[0079] S31, add xanthate in the ratio of 700g / t to the pulp obtained in step S2, get the required xanthate and mix it with water to make a 5% solution of xanthate, take xanthate sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com