Proton membrane fixing device used for dual-face coating

A technology of fixing device and coating device, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., and can solve problems such as high environmental requirements, membrane electrode hole defects, and depressions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following specific examples illustrate the present invention in further detail.

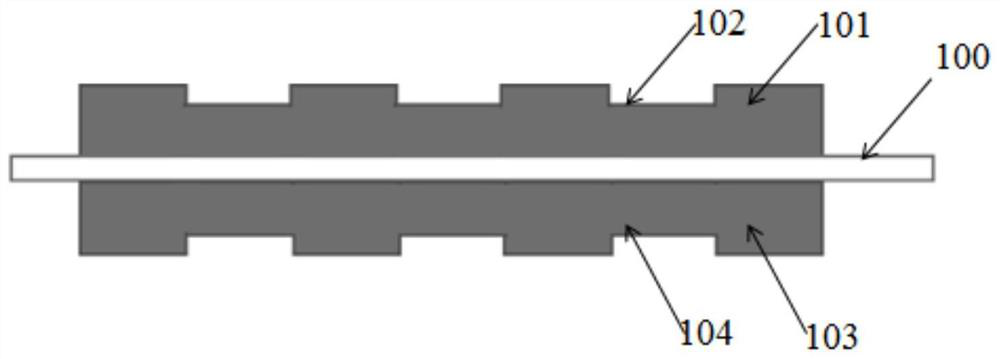

[0037] Such as figure 1 Shown is a schematic diagram of defects in the catalyst layer on the proton membrane in the prior art, which has been described in the background technology and will not be repeated.

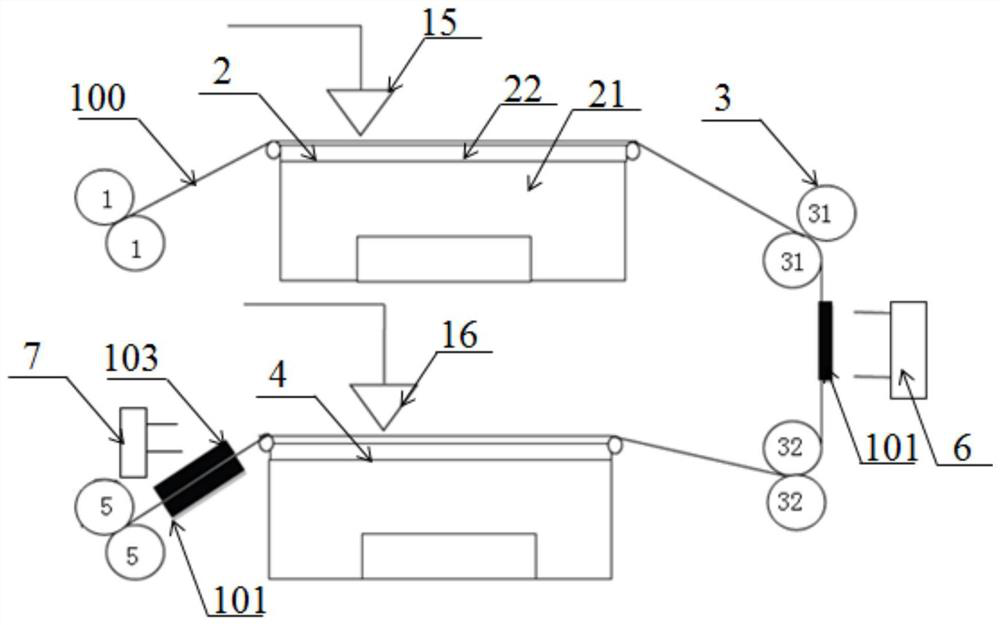

[0038] Such as figure 2As shown, a proton membrane fixing device for double-sided coating provided by the present invention includes a first traction roller group 1, an anode fixing device 2, an overturning device 3, and a cathode fixing device arranged in sequence along the advancing direction of the proton membrane 4. The second pulling roller set 5 , and the anode coating head 15 arranged above the anode fixing device 2 , and the cathode coating head 16 arranged above the cathode fixing device 4 . The anode fixing device 2 and the cathode fixing device 4 are correspondingly arranged on the same horizontal side of the turning device 3 up and down ( figure 2 middle left side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com