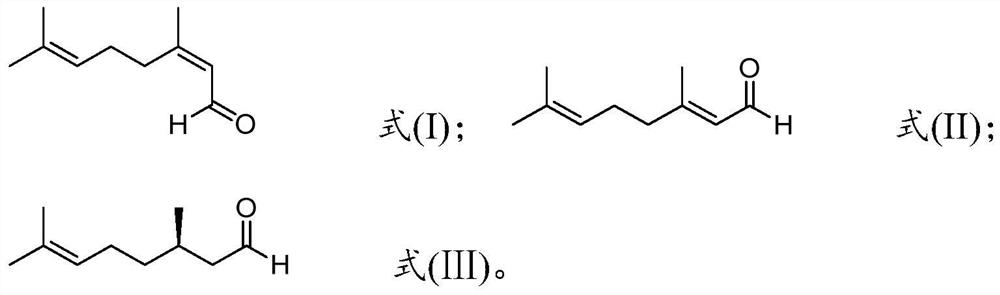

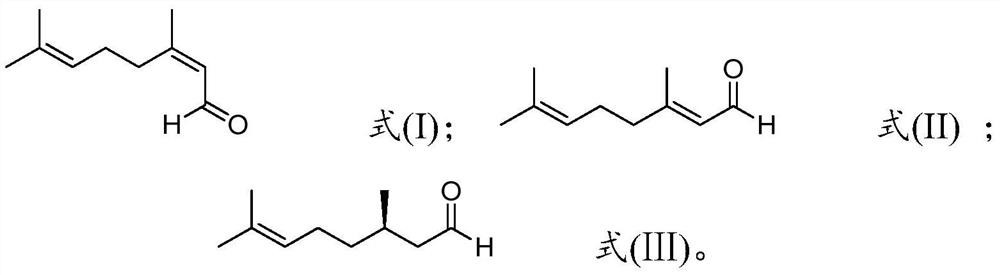

Method for preparing R-citronellal

A technology of citronellal and transition metals, applied in the field of R-citronellal preparation, can solve the problems of complex process operation, complex process, harsh recovery and application conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

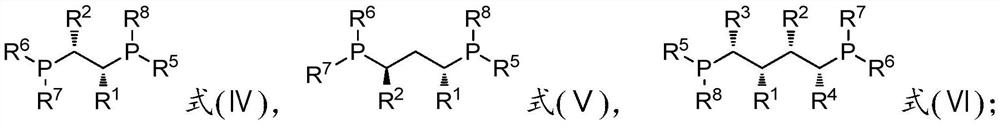

Method used

Image

Examples

Embodiment 1

[0064] Add 8.9 grams of montmorillonite (montmorillonite K10) and 1 gram of nanosilver (20- 40 nanometers), after stirring at 30° C. for 1 hour, the montmorillonite and nano-silver were removed by filtration through a closed filter.

[0065] 7.5mg Rh(CO) 2 acac (0.029mmol) and 18.6mg (S,S)-chiraphos (0.436mmol) were dissolved in the above 8836g geranial (the molar ratio of geranial / neral double bond isomer=99:1); The molar calculation of rhodium atom in, substrate / catalyst molar ratio=2000000), join in the reactor, by injecting hydrogen, reaction pressure is adjusted to 80 bar (reaction pressure, bar), be warming up to 90 ℃ (reaction temperature) After reacting for 8 hours (reaction time), the conversion rate and optical purity measured by gas chromatography are listed in Table 1.

Embodiment 2-9

[0067] Examples 2-9 were carried out with reference to Example 1, except for the selection of aluminosilicate, nano-silver, reaction temperature, reaction pressure and reaction time, see Table 1 for details.

[0068] Table 1

[0069]

Embodiment 10

[0071] Add 1 gram of montmorillonite K10 to 8836g of neral aldehyde (the molar ratio of neral / geranial double bond isomers=99:1) under nitrogen atmosphere, stir at 10°C for 20 hours, pass The airtight filter removes the montmorillonite by filtration.

[0072] 7.5mg Rh(CO) 2 acac (0.029mmol) and 13mg (R, R)-chiraphos (0.030mmol) were dissolved in the above 8836g neral (the molar ratio of neral / geranial double bond isomer=99:1; Rhodium atom meter, substrate / catalyst molar ratio=2000000), was added in the reaction kettle, the reaction pressure was adjusted to 80 bar by injecting hydrogen, after the temperature was raised to 90°C for 8 hours, the conversion rate was measured by gas chromatography to be 53 %, the cumulative conversion number is 1,056,000, and the optical purity is 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com