Repeated sealing packaging film for food, and preparation method thereof

A technology for packaging film and food, which is applied in the field of re-sealing packaging film for food and its preparation, and can solve the problems of reduced re-sealing performance of packaging film, inability to perform second or third sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

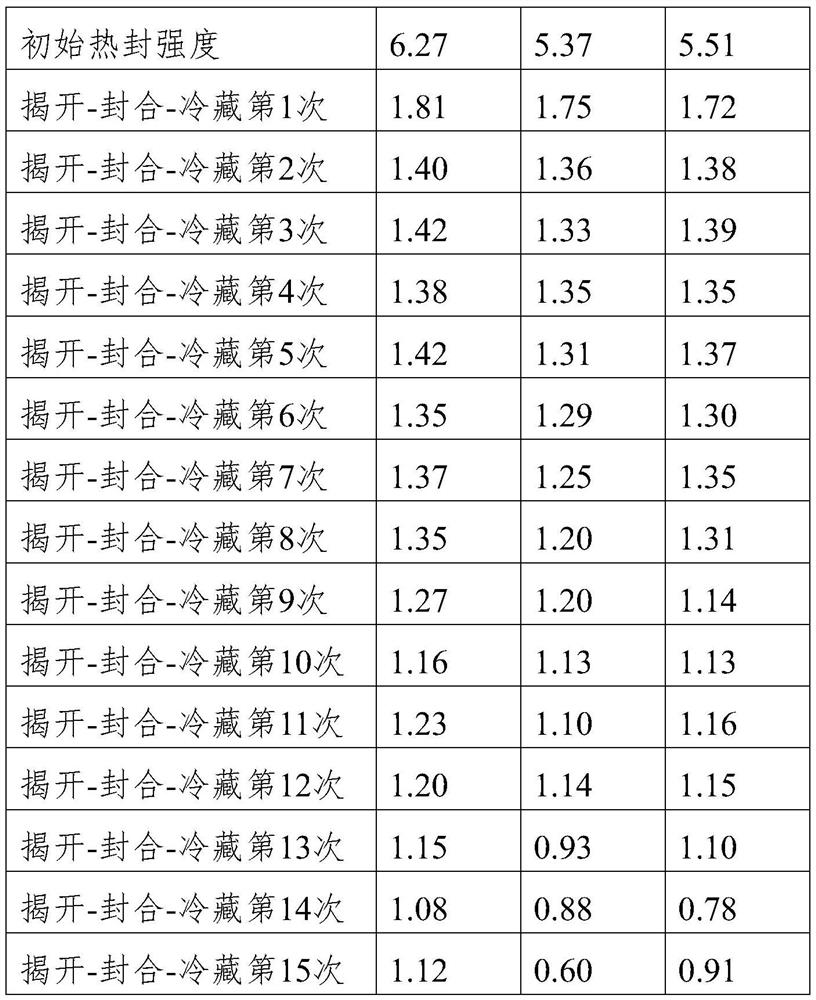

Embodiment 1

[0018] The present invention is a resealing packaging film for food, which comprises an outer layer, a middle layer, a cold adhesive layer and a heat-sealing layer stacked sequentially from outside to inside, and the outer layer and the middle layer include 45 parts by weight Parts of LLDPE, 25 parts of LDPE, 15 parts of HDPE, 4 parts of antioxidant; The cold adhesive layer includes 8 parts of natural rubber, 9 parts of SIS, 9 parts of SBS, 9 parts of EVA and 6-15 parts of nitrile rubber with an acrylonitrile content of 18-20%, 15 parts of tackifying resin, 10 parts of methyl methacrylate, 9 parts of butyl methacrylate, 11 parts of coupling agent modified calcium carbonate hollow particles, 16.5 parts of copolyester gum, 1.5 parts of ethylene thiourea, 4 parts of zinc oxide, 1.5 parts of phthalate softener, 1 part of microcrystalline wax, 1 part of N, N-zinc dibutylsulfurized aminobenzoate; the heat-sealing layer includes 54 parts by weight of LLDPE, 45 parts of LDPE, 1.2 part...

Embodiment 2

[0021] The present invention is a resealing packaging film for food, comprising an outer layer, a middle layer, a cold adhesive layer and a heat-sealing layer stacked sequentially from outside to inside, and the outer layer and the middle layer include 42 Parts of LLDPE, 23 parts of LDPE, 12 parts of HDPE, 3 parts of antioxidant; the cold adhesive layer includes 7 parts of natural rubber in parts by weight, 6 parts of SIS, 6 parts of SBS, 7 parts of EVA and 13 parts of nitrile rubber with acrylonitrile content of 18-20%, 12 parts of tackifying resin, 18 parts of butyl methacrylate, 10 parts of coupling agent modified calcium carbonate hollow particles, 15 parts of Copolyester glue, 1 part of ethylene thiourea, 2 parts of zinc oxide, 1.5 parts of phthalate softener, 1 part of propyl gallate, 1 part of ethyl phenyl dithioamino Zinc formate; the heat-sealing layer includes 52 parts by weight of LLDPE, 43 parts of LDPE, 1.1 part of anti-blocking agent, and 0.3 part of slippery age...

Embodiment 3

[0024] The invention is a resealing packaging film for food, which comprises an outer layer, a middle layer, a cold adhesive layer and a heat-sealing layer stacked sequentially from outside to inside, and the outer layer and the middle layer include 48 Parts of LLDPE, 28 parts of LDPE, 19 parts of HDPE, 5 parts of antioxidant; the cold adhesive layer includes 9 parts by weight of natural rubber, 6 parts of SIS, 6 parts of SBS, 12 parts of EVA and 15 parts of acrylonitrile content are nitrile rubber of 18-20%, 18 parts of tackifying resin, 20 parts of methyl methacrylate, 10-12 parts of coupling agent modified calcium carbonate hollow particles, 15 parts -18 parts of copolyester gum, 1-2 parts of ethylene thiourea, 2-6 parts of zinc oxide, 2 parts of phthalate softener, 1 part of propyl gallate, 0.5 parts of N, N-zinc dibutylsulfurized aminobenzoate, 0.5 parts of zinc ethylphenyl dithiocarbamate; the heat-sealing layer includes 50-58 parts by weight of LLDPE, 40-50 parts of LDP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com